Aluminum Extrusion Profiles Los Angeles for Motor Cylinder Shell

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Aluminium Extrusion Profiles For Motor Cylinder Shell Description

Aluminium Extrusion Profiles For Motor Cylinder Shell is one semi-finished aluminium material. It is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminium Extrusion Profiles For Motor Cylinder Shell

Aluminium Extrusion Profiles For Motor Cylinder Shell | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminium Extrusion Profiles For Motor Cylinder Shell

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminium Extrusion Profiles For Motor Cylinder Shell

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminium Extrusion Profiles For Motor Cylinder Shell

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

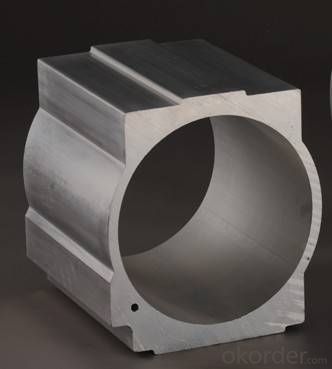

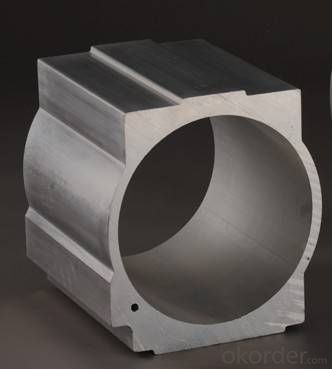

6. Image of Aluminium Extrusion Profiles For Motor Cylinder Shell

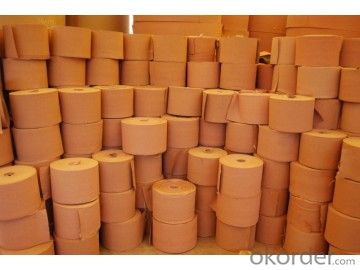

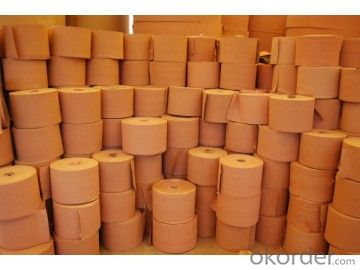

7. Package and shipping of Aluminium Extrusion Profiles For Motor Cylinder Shell

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum profiles suitable for sports equipment?

- Yes, aluminum profiles are suitable for sports equipment. Aluminum is a lightweight and durable material that offers several advantages for sports equipment manufacturing. It is known for its high strength-to-weight ratio, making it ideal for applications that require strength without adding unnecessary weight. Aluminum profiles are commonly used in the production of various sports equipment such as bicycles, golf clubs, baseball bats, tennis rackets, and even in the construction of sports stadiums and arenas. The lightweight nature of aluminum allows athletes to handle the equipment more easily, resulting in improved performance and reduced fatigue during sports activities. Additionally, the durability of aluminum ensures that the equipment can withstand the rigors of intense use and last for a longer time. The versatility of aluminum profiles also makes them suitable for sports equipment. They can be easily shaped, molded, and manipulated into various designs to meet specific performance requirements. This flexibility allows manufacturers to create equipment with the desired characteristics, such as improved aerodynamics, better balance, or enhanced shock absorption. Furthermore, aluminum profiles offer excellent corrosion resistance, which is particularly important for sports equipment that may be exposed to moisture, sweat, or harsh environmental conditions. This property ensures that the equipment remains functional and maintains its performance over time. In summary, aluminum profiles are indeed suitable for sports equipment due to their lightweight, durable, and versatile nature. With their high strength-to-weight ratio, they contribute to improved performance, reduced fatigue, and prolonged lifespan of the equipment.

- Q: Can aluminum profiles be used for shopfitting and retail displays?

- Certainly, shopfitting and retail displays can absolutely utilize aluminum profiles. Aluminum, being a versatile material, possesses the advantageous combination of lightweight properties with remarkable strength, making it an ideal choice for constructing structures and fixtures in retail spaces. The customization and fabrication of aluminum profiles are effortlessly achievable, enabling the creation of tailored designs to meet specific requirements, thus allowing for the utmost flexibility in developing diverse display and shopfitting solutions. Moreover, the sleek and contemporary aesthetic offered by aluminum profiles is frequently sought after in retail environments. Furthermore, their exceptional durability and resistance to corrosion guarantee their enduring presence in areas with high foot traffic. Overall, due to their versatility, strength, customization options, and aesthetic appeal, aluminum profiles are an exceptional selection for shopfitting and retail displays.

- Q: Are aluminum profiles suitable for use as exterior walls in residential buildings?

- <p>Yes, aluminum profiles can be used for exterior walls in residential buildings. They offer several advantages such as durability, low maintenance, and resistance to corrosion. Aluminum profiles are lightweight, which makes them easier to install compared to heavier materials. They also have good thermal conductivity, which can be managed with proper insulation to maintain energy efficiency. Additionally, aluminum can be powder-coated in various colors, offering design flexibility. However, it's important to ensure that the aluminum profiles meet building codes and standards for structural integrity and weather resistance.</p>

- Q: What are the minimum thickness specifications for aluminum alloy door and window profiles?

- 2, GB8479, 2005, "aluminum alloy door" in 5.1: aluminum alloy door force components should be determined by test or calculation. The minimum measured wall thickness shall be greater than 2.0mm without the surface treated profiles.

- Q: How do aluminum profiles perform in terms of water resistance?

- Aluminum profiles generally exhibit high water resistance due to their natural corrosion resistance and the protective oxide layer formed on their surface. This makes them highly suitable for applications exposed to water or high humidity environments. However, the performance can also depend on the specific alloy and surface treatment used.

- Q: Can aluminum profiles be used for stadium seating?

- Yes, aluminum profiles can be used for stadium seating. Aluminum profiles offer numerous advantages for stadium seating, making them a popular choice in modern stadium construction. Firstly, aluminum profiles are lightweight, which makes them easier to install and transport. This allows for faster construction times and reduces the overall weight load on the stadium structure. Secondly, aluminum profiles are highly durable and resistant to corrosion, making them suitable for outdoor applications where the seating is exposed to various weather conditions. This ensures that the stadium seating will remain in good condition for a longer time, reducing the need for frequent repairs or replacements. Additionally, aluminum profiles can be easily customized and fabricated into different shapes and sizes to meet the specific design requirements of the stadium. This flexibility allows for the creation of unique seating arrangements and configurations to optimize the spectator experience. Furthermore, aluminum profiles offer excellent strength-to-weight ratio, providing structural stability and support for the seating. This ensures the safety and comfort of spectators during events. In conclusion, aluminum profiles are a versatile and practical choice for stadium seating due to their lightweight nature, durability, customization options, and strength. They offer numerous benefits that contribute to the overall success and functionality of a stadium seating system.

- Q: Can aluminum profiles be used for retail displays?

- Indeed, retail displays can utilize aluminum profiles. These profiles possess a remarkable versatility that allows for customization to suit diverse design needs. Notably, they combine lightweight properties with superior strength, rendering them perfect for the construction of robust and enduring retail displays. Furthermore, aluminum profiles lend themselves to effortless shaping, cutting, and assembling, resulting in the creation of distinctive and captivating displays. By employing powder coating or anodization techniques, these profiles can attain a variety of colors and finishes, thereby enhancing the visual appeal of the retail environment. Moreover, through seamless integration with materials like glass, acrylic, or wood, aluminum profiles enable the production of multi-material displays. In conclusion, the remarkable flexibility, durability, and aesthetic charm of aluminum profiles establish them as an excellent choice for retail displays.

- Q: What are the dimensions of standard aluminum profiles?

- The dimensions of standard aluminum profiles can vary depending on the specific profile and its intended use. However, common dimensions for standard aluminum profiles typically range from a few millimeters to several inches in width and height, with lengths varying based on the manufacturer's specifications.

- Q: The number of aluminum profiles can be meters or KG. How exactly is it? How do you understand that?

- According to the calculated root.The general material company is used to calculate the weight or root. Few meters.

- Q: Are aluminum profiles suitable for use in exterior wall systems?

- <p>Yes, aluminum profiles are commonly used for exterior wall systems due to their durability, low maintenance, and resistance to corrosion and weathering. They offer a lightweight and strong alternative to traditional materials, and can be designed to provide thermal insulation and aesthetic appeal. Their versatility allows for various configurations and customizations, making them suitable for a wide range of architectural styles and requirements.</p>

Send your message to us

Aluminum Extrusion Profiles Los Angeles for Motor Cylinder Shell

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords