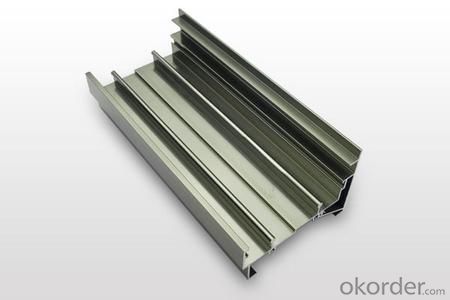

Aluminum Door Profiles for Aluminum Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium alloys with a wide range of properties are used in engineering structures. Alloy systems are classified by a number system (ANSI) or by names indicating their main alloying constituents (DIN and ISO).

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

One important structural limitation of aluminium alloys is their fatigue strength. Unlike steels, aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loadings. This implies that engineers must assess these loads and design for a fixed life rather than an infinite life.

Another important property of aluminium alloys is their sensitivity to heat. Workshop procedures involving heating are complicated by the fact that aluminium, unlike steel, melts without first glowing red. Forming operations where a blow torch is used therefore require some expertise, since no visual signs reveal how close the material is to melting. Aluminium alloys, like all structural alloys, also are subject to internal stresses following heating operations such as welding and casting. The problem with aluminium alloys in this regard is their low melting point, which make them more susceptible to distortions from thermally induced stress relief. Controlled stress relief can be done during manufacturing by heat-treating the parts in an oven, followed by gradual cooling—in effect annealing the stresses.

The low melting point of aluminium alloys has not precluded their use in rocketry; even for use in constructing combustion chambers where gases can reach 3500 K. The Agena upper stage engine used a regeneratively cooled aluminium design for some parts of the nozzle, including the thermally critical throat region.

Another alloy of some value is aluminium bronze (Cu-Al alloy).

- Q: This question asks for an overview of the various dimensions and forms of aluminum profiles that are specifically used in the construction of windows and doors.

- <p>Aluminum profiles for windows and doors come in a variety of sizes and shapes to accommodate different architectural designs and functional requirements. Common profiles include rectangular tubes for frame construction, square or rectangular profiles for sashes, and L-shaped profiles for corners. Sizes can range from thin, lightweight profiles suitable for residential use to heavy-duty, large-scale profiles for commercial applications. Shapes can be customized to fit specific window styles such as casement, sliding, or fixed, with dimensions varying from a few millimeters to several centimeters in width and thickness. The profiles are designed to provide structural integrity, weather resistance, and aesthetic appeal, with the ability to be combined in various configurations to create the desired window or door system.</p>

- Q: Do aluminum profiles have good thermal insulation properties?

- No, aluminum profiles do not have good thermal insulation properties. Aluminum is a highly conductive material, which means it allows heat to easily transfer through it. This conductivity makes aluminum profiles less effective in preventing heat transfer and thermal insulation compared to other materials such as wood or vinyl. To enhance the thermal insulation properties of aluminum profiles, they are often combined with thermal breaks or insulating materials to reduce heat loss or gain.

- Q: Can aluminum profiles be recycled and reused for interior wall cladding purposes?

- <p>Yes, aluminum profiles can be recycled and reused in interior wall cladding applications. Aluminum is a highly recyclable material, and its recycling process does not degrade its properties, making it an excellent choice for sustainable construction. Recycled aluminum profiles can be used to create new wall cladding systems, reducing waste and the environmental impact of mining and processing new aluminum. This practice not only conserves natural resources but also contributes to energy savings and a lower carbon footprint.</p>

- Q: What are the safety regulations concerning the use of aluminum profiles in construction?

- <p>Yes, there are safety regulations related to the use of aluminum profiles in construction. These regulations vary by country and region but generally include requirements for material strength, durability, and resistance to environmental factors. Standards such as ASTM B221 for aluminum and aluminum alloy extruded bars, rods, and profiles, and ISO 6361 for aluminum and aluminum alloy extruded profiles, provide guidelines on dimensions, tolerances, and mechanical properties. Compliance with local building codes and regulations is crucial, which may include fire resistance, load-bearing capacity, and corrosion resistance. Additionally, proper installation practices and adherence to manufacturer's specifications are essential to ensure safety and structural integrity.</p>

- Q: What are the reasons for the large number of products in the aluminum profile cutting machine after opening?

- When sawing, lubrication is insufficient, check the lubrication system, and the other may be aluminum material is not good

- Q: Can aluminum profiles be used in cleanroom environments?

- Yes, aluminum profiles can be used in cleanroom environments. Aluminum is a lightweight and versatile material that possesses many desirable qualities for cleanroom applications. It is non-corrosive, non-magnetic, and has a high strength-to-weight ratio, making it suitable for constructing cleanroom structures such as walls, partitions, and equipment racks. Aluminum profiles can be easily assembled and disassembled, allowing for flexible cleanroom configurations and future modifications. They can also be integrated with other materials like glass, acrylic, or stainless steel to meet specific cleanroom requirements. Additionally, aluminum profiles can be anodized or coated to enhance their cleanliness and resistance to contamination. Anodization provides a protective layer on the surface of the aluminum, making it more resistant to scratches and wear. Coatings such as epoxy or powder coatings can further improve the durability and cleanliness of the profiles. Overall, aluminum profiles offer numerous advantages for cleanroom applications, including their lightweight nature, strength, corrosion resistance, and flexibility in design.

- Q: Explain if aluminum profiles can be utilized in constructing energy-efficient building systems and if so, how they contribute to energy efficiency.

- <p>Yes, aluminum profiles can be used to create energy-efficient building systems. They are lightweight yet strong, which reduces the energy required for construction. Aluminum profiles also have excellent thermal conductivity, allowing them to be used in double-glazed windows and doors, improving insulation and reducing heat loss. Additionally, aluminum can be easily recycled, reducing the energy needed for new materials. Their high reflectivity can also help in reducing heat absorption, further contributing to energy efficiency.</p>

- Q: Which is the highest price of aluminum profile 60616063?

- 6063 general construction profiles, that is industrial profiles

- Q: How do aluminum profiles perform in earthquake-resistant structures?

- There are numerous advantages of using aluminum profiles in earthquake-resistant structures. Firstly, aluminum is a lightweight material, meaning it possesses a high strength-to-weight ratio. This quality enables aluminum profiles to provide exceptional structural integrity while minimizing the overall weight of the building. This becomes particularly important in areas prone to earthquakes as it reduces the forces exerted on the structure during seismic events. Furthermore, aluminum exhibits high ductility, allowing it to deform significantly without losing its strength. This property enables aluminum profiles to absorb and dissipate seismic energy, effectively reducing potential damage to the structure. Additionally, the ductility of aluminum ensures its ability to withstand the lateral forces and vibrations generated during an earthquake, providing enhanced stability to the building. Moreover, aluminum profiles possess outstanding corrosion resistance, making them ideal for earthquake-resistant structures in coastal regions or areas with high humidity. This corrosion resistance guarantees the durability and longevity of the structure, even in harsh environmental conditions. Additionally, aluminum profiles can be easily fabricated and assembled, offering versatility in design and construction. This flexibility allows architects and engineers to optimize the structural performance of the building, taking into account the specific seismic requirements of the region. In conclusion, due to their lightweight nature, high strength-to-weight ratio, ductility, corrosion resistance, and ease of fabrication, aluminum profiles excel in earthquake-resistant structures. These characteristics make aluminum profiles a dependable choice for ensuring the safety and stability of buildings in areas prone to seismic activity.

- Q: Are aluminum profiles suitable for decorative applications?

- <p>Yes, aluminum profiles are commonly used for decorative purposes. They offer a sleek, modern look and are lightweight, durable, and resistant to corrosion. They can be anodized or powder coated in various colors to match different design aesthetics. Aluminum profiles are versatile and can be used in architectural features, furniture, and various other decorative elements.</p>

Send your message to us

Aluminum Door Profiles for Aluminum Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords