Aluminum Decorative Sheets - AA5XXX Mill-Finished Aluminum Sheets for Construction in Las Vegas

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

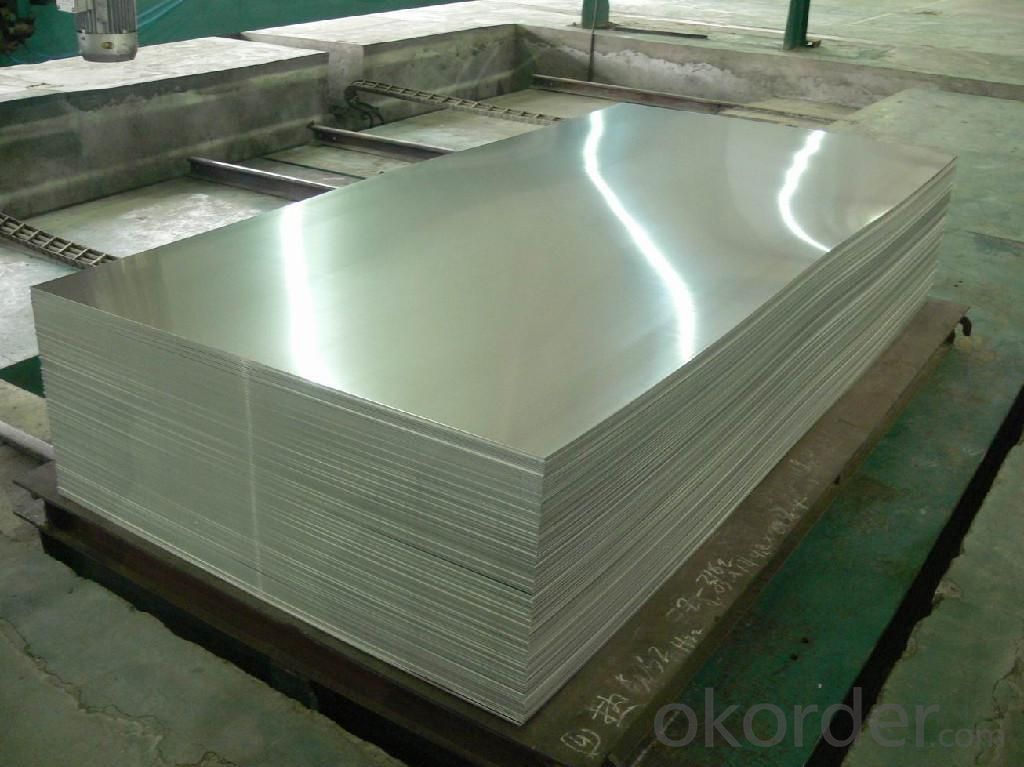

1.Structure of AA5xxx Mill-Finished Aluminum Sheets Used for Construction Description

AA5xxx Mill-Finished Aluminum Sheets Used for Construction is cut from aluminum coils 5xxx. The aluminum content of aluminum sheets 1xxx C.C quality is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA5xxx Mill-Finished Aluminum Sheets Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AA5xxx Mill-Finished Aluminum Sheets Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

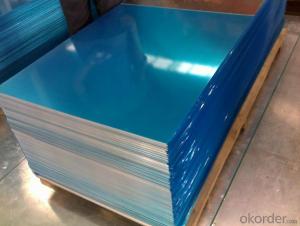

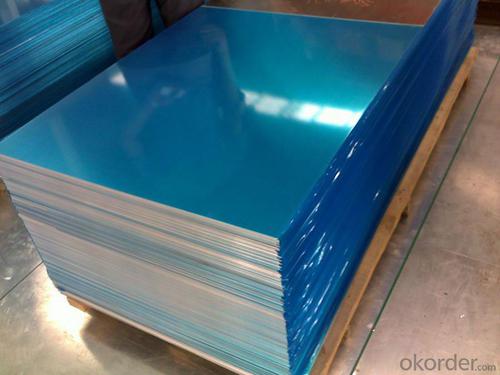

3.AA5xxx Mill-Finished Aluminum Sheets Used for Construction Images

4.AA5xxx Mill-Finished Aluminum Sheets Used for Construction Specification

Alloy | AA5xxx (AA5754,AA5083 etc) |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA5xxx Mill-Finished Aluminum Sheets Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA5xxx Mill-Finished Aluminum Sheets Used for Construction.

B.When will you deliver the products?

AA5xxx Mill-Finished Aluminum Sheets Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: Can aluminum sheets be used for cookware?

- Yes, aluminum sheets can be used for cookware. Aluminum is a popular choice for cookware due to its excellent heat conductivity and lightweight nature. However, it is often used as a core material with other coatings or layers added to enhance its durability and prevent chemical reactions with acidic foods.

- Q: What is the main influence of the spacing?What are the main effects of spacing?

- Thermal explosion is related to a lot of factors. As to how much impact the lining board has on the thermal explosion, it's really impossible to speak of it. I think it has very little influence

- Q: What are the different surface finishes available for aluminum sheets?

- There are several different surface finishes available for aluminum sheets, each offering distinct characteristics and aesthetic appeal. Some of the commonly used surface finishes for aluminum sheets include: 1. Mill Finish: This is the most basic surface finish and is achieved by leaving the aluminum in its as-rolled condition, without any additional treatment. It has a smooth and shiny appearance, but may have minor imperfections and is not as durable as other finishes. 2. Anodized Finish: Anodizing is an electrochemical process that creates a protective layer on the surface of the aluminum sheet. This finish enhances corrosion resistance, improves durability, and provides a wide range of color options. Anodized finishes can have a matte or glossy appearance. 3. Brushed Finish: This finish is achieved by brushing the aluminum sheet with a fine abrasive material, creating a textured pattern. This finish is commonly used for decorative purposes and provides a unique and attractive appearance. 4. Polished Finish: Polishing the aluminum sheet using abrasive materials creates a smooth and reflective surface. This finish is often used for decorative purposes and gives a high-end, mirror-like appearance to the aluminum. 5. Embossed Finish: Embossing is a process that creates raised or recessed patterns on the surface of the aluminum sheet. This finish is commonly used for decorative purposes, as it adds texture and visual interest to the material. 6. Powder Coated Finish: Powder coating involves applying a dry powder to the aluminum sheet and then curing it under heat. This finish provides a durable and weather-resistant coating, and is available in a wide range of colors and textures. 7. Patterned Finish: Patterned finishes are achieved by imprinting different patterns or designs on the surface of the aluminum sheet. This finish is often used for architectural applications and adds visual interest to the material. These are just a few examples of the different surface finishes available for aluminum sheets. The choice of finish depends on the desired appearance, functionality, and application requirements.

- Q: Are aluminum sheets suitable for electrical transformers?

- Indeed, electrical transformers can certainly make use of aluminum sheets. Aluminum, being a highly conductive material, presents numerous benefits when employed in transformers. Primarily, its electrical resistance is lower in comparison to other materials such as copper, enabling efficient transmission of electrical energy. Consequently, this leads to reduced energy losses and enhanced overall performance. Furthermore, aluminum possesses the advantage of being lightweight, rendering it easier to handle and install. Moreover, it is also more economical than copper, thus making it the preferred option for extensive transformer applications. All in all, aluminum sheets offer a dependable and effective resolution for electrical transformers.

- Q: This question asks for a comparison of aluminum sheets with other materials regarding their cost and performance.

- <p>Aluminum sheets are generally cost-effective and offer excellent performance compared to many other materials. They are lightweight, which reduces material and transportation costs. They also have high strength-to-weight ratios, making them durable and resistant to corrosion. In terms of performance, aluminum sheets are versatile, used in various industries such as construction, automotive, and aerospace. They conduct heat and electricity well, which is beneficial for applications requiring thermal or electrical conductivity. However, they may be more expensive than some plastics or cheaper metals like steel on a per-unit basis, but their lower weight and durability often offset this cost over time.</p>

- Q: To an idiot, this may seem like a stupid question: its just aluminum. But it may not be.However seeing that I am only a high school student and don't have access to aluminum power (which is what I desire for an independent experiment) so I'd like to grind consumer grade aluminum foil down bases of Mohs scale of Hardness.My concern is that aluminum foil is Aluminum oxide which is a 9 (10 being diamond, 1 being talcum powder) and this would be horribly difficult to grind.If it is Alumina, that's only a 3.5.If it does happen to be aluminum oxide, can you think of a way to remove the Oxygen. Would nitric acid work.

- Thermite or meth?

- Q: How much weight/people can a 12ft aluminum boat hold?and if anyone knows how much weight can a 6.5hp motor push around

- there okorder / Weight Capacity 335 lb / 151kg Max. Person Capacity 2 Max. HP Capacity 3 hp / 2kw Max. Person Weight Capacity 295 lb / 133kg Hull Gauge .050 / 1.27mm Package Length 18' / 5.49m Seats 3 the 6.5hp ob will push the capacity weight of the boat with out a problem, but may not be able to bring the boat onto a plane. hope this helps

- Q: Are aluminum sheets suitable for use in electrical applications?

- Aluminum sheets are indeed appropriate for utilization in electrical applications. The reason for this appropriateness lies in aluminum's remarkable ability to conduct electricity. Its exceptional conductivity enables the efficient transmission of electrical current. In fact, aluminum sheets are frequently employed in electrical applications including power transmission lines, electrical wiring, and electrical enclosures. Furthermore, aluminum's lightweight nature facilitates easier handling and installation. It also possesses resistance against corrosion, ensuring prolonged durability and reliability within electrical systems. Nevertheless, it is crucial to acknowledge that aluminum exhibits lower conductivity in comparison to copper. Consequently, compensating for this disparity may require the use of larger gauge sizes. In summary, aluminum sheets serve as a feasible and cost-effective choice for a variety of electrical applications.

- Q: Can aluminum sheets be used for reflectors?

- Indeed, reflectors can utilize aluminum sheets. Renowned for its remarkable reflectivity properties, aluminum emerges as an optimal substance for a multitude of reflector applications. Its exceptional reflectivity empowers it to deftly redirect and bounce light, rendering it fitting for deployment in diverse devices such as illumination apparatus, solar panels, telescopes, and other instruments that necessitate precise and effective light reflection. Moreover, aluminum's lightweight nature, durability, and resistance to corrosion render it a pragmatic selection for reflectors that must endure formidable environmental circumstances.

- Q: Are aluminum sheets suitable for storage tanks?

- Yes, aluminum sheets can be suitable for storage tanks depending on the specific requirements and purpose of the tank. Aluminum is a lightweight and corrosion-resistant material, making it an excellent choice for various storage applications. It offers good structural integrity and durability, with the ability to withstand harsh environments and weather conditions. Additionally, aluminum has a high strength-to-weight ratio, which means it can handle heavy loads while remaining relatively lightweight. However, it is important to consider the contents of the storage tank and consult with experts to ensure that aluminum is the appropriate material choice for the specific storage requirements.

Send your message to us

Aluminum Decorative Sheets - AA5XXX Mill-Finished Aluminum Sheets for Construction in Las Vegas

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords