Anodized AA8XXX Mill Finished Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA8xxx Mill Finished Aluminum Sheets Used for Construction Description

AA8xxx Mill Finished Aluminum Sheets Used for Construction is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA8xxx is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2.Main Features of AA8xxx Mill Finished Aluminum Sheets Used for Construction

1)Excellent weather-proof durability

2)Anti-ultraviolet

3)High erosion resistance

4)Stable color and gloss

5)Good mechanical processing performance

6)Abrasion resistance

7)Anti-impact

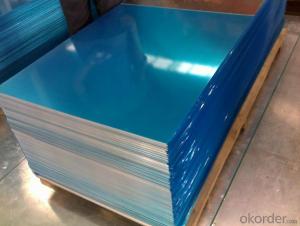

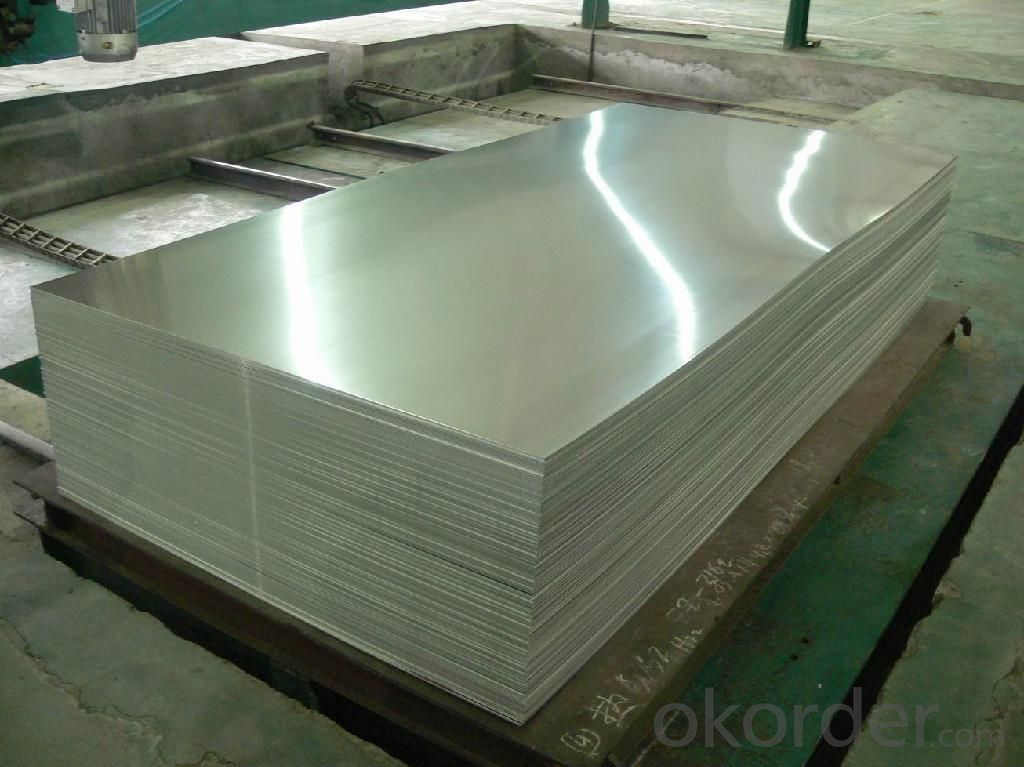

3.AA8xxx Mill Finished Aluminum Sheets Used for Construction Images

4.AA8xxx Mill Finished Aluminum Sheets Used for Construction Specification

Alloy | AA8xxx |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: I have to wire solar DC photovoltaic panels and have always used at least an 8 gauge wire. Recently, I installed a solar electric fence and they recommended special electric fence wire that can handle 10,000 volts. It looks aluminum. The fence techs told me copper is only rated for 600 volts. And the power will leak through the insulation. They also say copper will corrode and created insulated spots. Does this mean that aluminum doesn't corrode and is it superior to copper? Is is all a lobbying scam to force us to buy copper? Can I use the electric fence wire in my solar wiring?

- I believe the fence techs are mistaken. On an electric fence, the wire is basically bare, and the periodic 10 kV shocks are very low current. Aluminum is cheap, and once it develops surface oxidation, will last. Copper would last, too - it would just cost more. For photovoltaic panels, copper is almost always the wire of choice. At #8 or larger, use stranded, of course. Copper has less resistance, which will be important in low-voltage PV. Also, aluminum wire cannot be simply put into fittings designed for copper; it must use special fittings designed for aluminum, or connected to copper with a wire nut and antioxidant.

- Q: Is it possible to utilize aluminum sheets for creating signs or banners?

- <p>Yes, you can use aluminum sheets to make signs or banners. Aluminum is a popular choice due to its durability, lightweight, and resistance to weather conditions. It can be easily cut, shaped, and printed on, making it ideal for outdoor signage. Additionally, aluminum sheets can be coated or laminated to enhance their visual appeal and protect against scratches and fading.</p>

- Q: What is the typical hardness of aluminum sheets?

- The hardness of aluminum sheets can differ based on the particular alloy and temper, resulting in a range of 40 to 70 on the Brinell hardness scale (HB). This level of hardness facilitates the ease of forming, machining, and fabricating aluminum sheets, rendering them applicable in various industries such as aerospace, automotive, construction, and manufacturing. Notably, the hardness of aluminum sheets can be enhanced further by undergoing heat treatment processes like annealing or hardening, allowing them to meet specific demands and enhance their mechanical properties.

- Q: Can the aluminum sheets be used for manufacturing automotive radiators?

- Indeed, automotive radiators can be manufactured using aluminum sheets. The lightweight nature of aluminum, along with its exceptional heat transfer qualities and resistance to corrosion, make it a favored material for automotive radiators. The malleability of aluminum sheets allows for effortless shaping and sizing to meet the specific requirements of radiator construction. Furthermore, aluminum radiators outperform traditional copper radiators in terms of cooling efficiency. Consequently, employing aluminum sheets for the production of automotive radiators is a feasible and beneficial choice.

- Q: How do aluminum plates drill?

- There are many drilling equipment for aluminium sheets,First, the engraving machine can be big or small, and can shape strange.

- Q: Would a chemical reaction happen between a piece of copper and a liquid solution containing a compound of aluminum? Why or why not? FIRST BEST ANSWER GETS POINTS!

- Since Al is more reactive than Cu, no reaction would occur. A reaction would occur only if you had a piece of Al and a solution containing Cu2+ ions. The more active metal replaces the other metal in solution and the less active metal plates out.

- Q: How to press multilayer aluminum sheets (aluminum sheet's thickness: 0.2mm) together and keep them inseperate after pressing?

- resistance welding is a welding method that pressing the materials to be welded in an area between two poles and switching on current. the current will go through the contact surface and agjacent area, producing resistance heat effect which will heatthe materials into melting or plastic state and make the materials be welded together.

- Q: Are aluminum sheets suitable for architectural roofing?

- Yes, aluminum sheets are suitable for architectural roofing. Aluminum is a lightweight material that is resistant to corrosion, making it an ideal choice for roofing applications. It is also highly durable and can withstand harsh weather conditions, including extreme temperatures, UV radiation, and strong winds. Additionally, aluminum sheets are available in a variety of colors and finishes, allowing for flexibility in design and aesthetics. Moreover, aluminum is a sustainable and environmentally friendly material as it can be recycled indefinitely without losing its properties. Overall, aluminum sheets provide excellent performance and versatility, making them a popular choice for architectural roofing.

- Q: Are 101 aluminum sheets suitable for food-grade applications?

- No, 101 aluminum sheets are not suitable for food-grade applications.

- Q: Can aluminum sheets be used for elevator interiors?

- Yes, aluminum sheets can be used for elevator interiors. Aluminum is a popular material choice for elevator interiors due to its various advantageous properties. It is lightweight, durable, and resistant to corrosion, making it suitable for long-term use in elevator applications. Aluminum sheets can be easily fabricated and shaped to fit the dimensions and design requirements of elevator interiors. Additionally, aluminum can be finished with different types of coatings or finishes, such as anodizing or powder coating, to enhance its appearance and provide additional protection. Overall, aluminum sheets are a viable option for elevator interiors and are commonly used in the industry.

Send your message to us

Anodized AA8XXX Mill Finished Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords