Aluminum Composite Panel Wall Cladding ACP - Aluminum Sheets Denver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

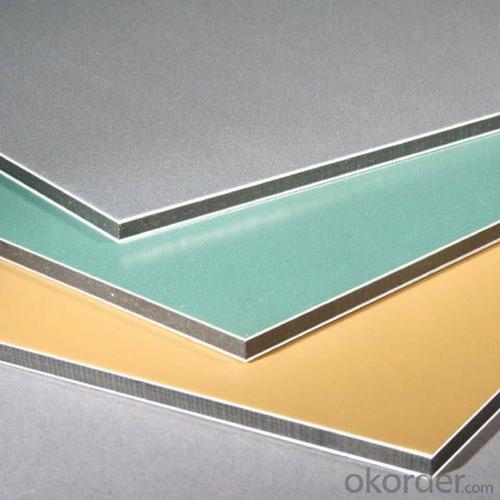

Structure of ACP Description:

Aluminum Composite Panel is a composite material made of aluminum and non-combustible mineral filled core. Though the core material does contain a small amount of combustible polyethylene, the main ingredient of the non-combustible mineral filled core does not permit the proliferation of flame and restricts smoke. It is a fire-safe material that passes mandatory requirements for exterior and interior application.It is an ideal material for external claddings, roof of pedestrian passage and other architectural applications.

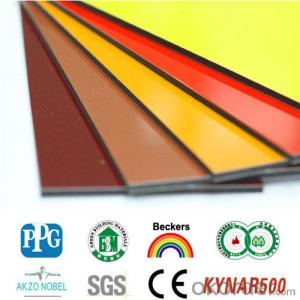

Main Features of ACP:

1) Super werther resistance

2) Light weight easy to process

3) Excellent fire resistance

4) Excellent impact strength

5) Uniform and colorful coating

6) Easy maintenance...and so on

7) Within 15 work days after receiving the first deposite payment .

Images of ACP:

ACP Specifications:

Standard size | 1220*2440*3mm and 1220*2440*4mm |

Accepted Width | Max:1580mm |

Accepted Length | Max:6000mm |

Accepted Thickness | 2mm,3mm,4mm,5mmm,6mm |

Aluminum alloy thickness | 0.10mm0.15mm0.18mm0.21mm0.25mm0.3mm0.35mm0.40mm0.45mm0.50mm |

Weight | 5 kg/m2 base on 4*0.4mm |

Nonstandard | sizes are available according your requirement |

FAQ of ACP:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 20000㎡.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Are 101 aluminum sheets magnetic?

- Negative, 101 sheets of aluminum lack magnetic properties. Aluminum, being a non-magnetic metal, does not possess the ability to allure or retain magnetic forces.

- Q: What are the different methods for punching aluminum sheets?

- There are several methods for punching aluminum sheets, including manual punching with hand tools, mechanical punching using punch presses, and CNC punching using computer-controlled machines. Each method has its own advantages and is chosen based on factors such as the required precision, volume of production, and complexity of the punched shapes.

- Q: Can aluminum sheets be used for elevator panels?

- Yes, aluminum sheets can be used for elevator panels. Aluminum is a versatile and durable material that is commonly used in construction and architectural applications, including elevator interiors. It offers several advantages such as being lightweight, corrosion-resistant, and easy to clean. Aluminum panels can be customized to fit the specific design requirements of elevator interiors and can be finished with different surface treatments or coatings to enhance their appearance and durability. Additionally, aluminum is a sustainable material as it is highly recyclable, making it an environmentally-friendly choice for elevator panels.

- Q: What is the lifespan of the aluminum sheets?

- The lifespan of aluminum sheets can vary depending on various factors such as the quality of the material, the environment they are exposed to, and the maintenance they receive. However, with proper care and maintenance, aluminum sheets can last for several decades.

- Q: What are the different methods of surface etching for aluminum sheets?

- Aluminum sheets can be surface etched using various methods, each offering unique benefits and applications. Some commonly used methods include: 1. Chemical etching: This technique involves selectively removing a thin layer of aluminum from the surface using a chemical solution. The solution typically contains acids or alkaline substances that dissolve the metal, resulting in a textured or patterned surface. Chemical etching is ideal for decorative or aesthetic purposes due to its precision and ability to achieve intricate designs. 2. Mechanical etching: Also known as abrasive blasting or sanding, this method physically removes the top layer of aluminum using abrasive materials like sandpaper or wire brushes. It can be done manually or with the help of machinery and is commonly used to create a uniform matte finish or prepare the surface for painting or coating. 3. Electrochemical etching: In this method, an electrical current is used to selectively dissolve the aluminum surface. The aluminum sheet is immersed in an electrolyte solution, and a direct current is applied through a stencil or mask to create the desired pattern. Electrochemical etching is commonly employed for marking or labeling on aluminum sheets, as it produces clear, permanent, and highly precise designs. 4. Laser etching: Laser etching involves using a high-powered laser to permanently remove the top layer of aluminum, creating precise patterns on the surface. This method is highly accurate and capable of achieving intricate designs with sharp edges. Industrial applications, such as marking serial numbers, logos, or barcodes on aluminum sheets, commonly utilize laser etching. 5. Photochemical etching: This technique employs a photosensitive material, called a photoresist, to create patterns on the aluminum surface. The aluminum sheet is coated with the photoresist, exposed to UV light through a stencil or mask, and then developed to remove the unexposed areas. The exposed aluminum is subsequently etched away using a chemical solution. Photochemical etching is frequently used for producing high-resolution designs or microstructures on aluminum sheets. When selecting the appropriate surface etching method for aluminum sheets, it is essential to consider factors such as precision, speed, cost, and complexity, as each method has its own advantages depending on the desired outcome and application.

- Q: How do you achieve a mirror-like finish on aluminum sheets?

- To achieve a flawless mirror-like appearance on aluminum sheets, a series of procedures must be undertaken to eliminate any flaws and create a sleek, reflective surface. The crucial steps involved are as follows: 1. Surface preparation: Commence by meticulously cleansing the aluminum sheet to eliminate any dirt, grease, or other contaminants. Utilize a mild detergent and water to accomplish this task. Thoroughly rinse the surface and ensure it is completely dry. 2. Sanding: Employ increasingly finer grades of sandpaper or abrasive pads to eliminate any scratches, oxidation, or unevenness on the aluminum surface. Begin with a coarser grit (around 120-180) and gradually progress to finer grits (up to 1000 or higher) to attain a smoother texture. It is essential to sand consistently in one direction to avoid visible scratches. 3. Polishing compounds: Administer a polishing compound or specialized metal polish designed explicitly for aluminum surfaces. Employ a soft cloth or a buffing wheel to apply the polish and work it into the surface. Apply gentle pressure and distribute the polish evenly by executing circular motions. Repeat this step until the desired level of shine is achieved. 4. Buffing: Utilize a buffing wheel, preferably composed of felt or cotton, to further enhance the luster. Apply a small quantity of a high-quality polishing compound to the wheel and meticulously buff the aluminum sheet in a consistent manner. Employ circular motions and maintain an unwavering, even pressure. 5. Final polishing: To attain an impeccable mirror-like finish, employ a specialized aluminum polish or a metal finishing compound. Apply a small amount onto a clean cloth and gently rub the surface using circular motions. This final step aids in eliminating slight scratches or imperfections, augmenting the brilliance of the aluminum sheet. Remember to meticulously cleanse the aluminum sheet after each step to eliminate any residue or excess polish. Furthermore, always adhere to the manufacturer's instructions when utilizing specific polishing compounds or tools as they may provide specific guidelines for optimal outcomes. By diligently following these steps, you can achieve a mirror-like finish on aluminum sheets, transforming them into highly reflective surfaces that are visually captivating and functionally efficient.

- Q: What is the typical fracture toughness of aluminum sheets?

- The typical fracture toughness of aluminum sheets can vary depending on the specific alloy and temper, but it is generally in the range of 20 to 35 MPa√m.

- Q: Can aluminum sheets be used for roofing applications?

- Yes, aluminum sheets can be used for roofing applications. Aluminum is a durable and lightweight material that offers excellent resistance to corrosion, making it suitable for use in roofing. It is commonly used in residential and commercial roofing projects due to its longevity and ability to withstand various weather conditions.

- Q: Are aluminum sheets conductive?

- Indeed, aluminum sheets possess conductivity. Being a metal, aluminum exhibits exceptional electrical conductivity. Consequently, aluminum sheets facilitate the smooth passage of electricity, rendering them suitable for an array of applications that necessitate conductivity, including electrical wiring, power transmission lines, and electronic devices.

- Q: Can aluminum sheet be used for automotive applications?

- Indeed, aluminum sheet finds its application in the automotive industry. Offering a combination of lightness and strength, aluminum serves as a highly advantageous material. Car bodies, hoods, doors, and various structural components are extensively manufactured using aluminum. The preference for aluminum sheets in these applications stems from their exceptional strength-to-weight ratio, resistance against corrosion, and durability. Moreover, aluminum exhibits ease in forming, enabling the attainment of intricate shapes and designs. The utilization of aluminum in automotive applications further contributes to enhanced fuel efficiency and reduced emissions due to its reduced weight. Ultimately, the manifold advantageous characteristics of aluminum sheets render them a suitable choice for automotive applications.

Send your message to us

Aluminum Composite Panel Wall Cladding ACP - Aluminum Sheets Denver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords