Aluminum Coils Price - PE/PVDF Painted Aluminum Coil for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Description of PE/PVDF Painted Aluminum Coil for Construction

| Alloy No. | Thickness (mm) | Width (mm) | Temper | |

| A1050,A1060, A1070,A1100,A1235,A1245 | 0.2-3.0 | 20-2200 | O,H12,H22,H14,H24,H16,H26,H18 | |

| 4.0-12.0 | 1000-2200 | H111,H112 | ||

| A3003,A3004,A3105 | 0.2-4.0 | 20-2200 | O,H12,H22,H14,H24,H16,H26,H18 | |

| 4.0-12.0 | 1000-2200 | H111,H112 | ||

| A5052,A5083,A5754,A5005 | 0.2-4.0 | 20-2200 | O,H12,H22,H14,H24,H16,H26,H18 | |

| 4.0-12.0 | 1000-2200 | H111,H112 | ||

| A6061,A6082,A6063 | 0.8-3.0 | 20-2200 | O | |

| A8011,A1145,A1235 | 0.005-0.2 | 20-2200 | O,,H18,H24 | |

| ID | 76mm,152mm,200mm,300mm,505mm | |||

| Packing : Export wooden pallets, wooden case | ||||

| Standards:ASTM-B209. EN573-1, GB/T3880.1-2006 | ||||

| Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set | ||||

2. Application of PE/PVDF Painted Aluminum Coil for Construction

Mainly used insigns, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect

3. Feature of PE/PVDF Painted Aluminum Coil for Construction

1.High temperature resistant

2.Weathering resistant

3.Scrubbing resistant

4.Sound insulation

5.Acid or alkali proof

6. Fireproof

7.Light weight material is easy to construct and install

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

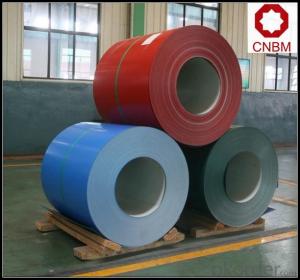

5. Image of PE/PVDF Painted Aluminum Coil for Construction

5. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How are aluminum coils joined together to form larger panels?

- Coil joining or coil-to-panel joining is the technique employed to combine aluminum coils into larger panels. To accomplish this, aluminum coils are fed into a coil joining machine, specifically designed for seamless connection of multiple coils. To initiate the process, the individual coils are inserted into the machine. The machine then unwinds the coils and brings them together, aligning them side by side. Typically, the edges of the coils slightly overlap to ensure a secure and uninterrupted connection. Once aligned, the machine implements various methods to bond the coils together. One prevalent approach involves the application of heat and pressure. By heating the overlapping edges of the coils, the aluminum softens and fuses together. Simultaneously, pressure is applied to ensure a robust bond. Alternatively, mechanical fasteners can be utilized to join the aluminum coils. In this case, the machine punches holes through the overlapping edges and inserts fasteners, such as screws or rivets, for a secure hold. Following the joining process, the machine continues to feed the connected coils forward, facilitating continuous production of larger panels. Excess material from the overlapping edges is typically trimmed off, resulting in a sleek and seamless panel. Overall, precision and specialized machinery are essential for the process of joining aluminum coils to create larger panels. The resulting panels possess durability, lightweight properties, and find widespread application in industries such as construction, automotive, and aerospace.

- Q: What causes tower after cutting aluminum coil

- Insulation aluminum coil will appear when the cooling bending phenomenon, reason is generally under the conditions of air cooling, the heat transfer coefficient of the aluminum coil insulation parts in contact with the air were flat, but because the wall thickness or different shapes, different parts of the heat dissipation rate is not balanced, resulting in thick wall or hollow tube heat faster than the thin Department of slow, resulting in insulating aluminum roll cooling occurs to the hollow part.

- Q: Can aluminum coils be used for signage purposes?

- Signage purposes can indeed utilize aluminum coils. Aluminum, as a lightweight and versatile material, finds common use in the signage industry. It possesses exceptional resistance to corrosion, rendering it suitable for both indoor and outdoor applications. Aluminum coils are easily cut and molded into diverse shapes and sizes, enabling the creation of customized signage designs. Moreover, aluminum exhibits high durability and can endure harsh weather conditions, ensuring longevity for signage. Coils can be painted or coated with various finishes to achieve desired aesthetics, while simultaneously safeguarding against fading and scratching. Ultimately, aluminum coils remain a favored choice for signage due to their versatility, durability, and aesthetic appeal.

- Q: The specification of thermal insulating aluminum coil

- 4-0 In general, the chemical engineering products for thermal insulation is 0. According to the International standard, the thickness tolerance is +-5%.02MM. according to industrial standard, it is +-0. The production crafts are embossed and plain sheet.

- Q: What industries commonly use aluminum coils?

- Aluminum coils are commonly used in a variety of industries including automotive, aerospace, construction, HVAC (heating, ventilation, and air conditioning), electrical, packaging, and transportation.

- Q: I have a aluminum sign that I store in the garage and it got a couple specks of rust on it which I don't like because I use it for my DJ shows. How can I get rid of the rust before it gets too bad without painting over it?

- Aluminum dont rust!! If theres rust on it then its not alum, or it was laying against something steel that was rusty and the rust got onto the alum.. If it's the ladder it should wipe off pretty easy with a clean rag and alittle elbow grease.. Or you can use window cleaner, wd-40, or even tooth paste on a rag to wipe it off.

- Q: Can aluminum coils be used for HVAC condenser coils?

- Indeed, HVAC condenser coils can utilize aluminum coils. In recent times, aluminum coils have gained significant popularity owing to their myriad benefits over conventional copper coils. With their lighter weight and enhanced durability, aluminum coils exhibit superior resistance to corrosion. Additionally, they boast exceptional heat transfer properties that enable efficient refrigerant cooling. Furthermore, aluminum coils prove to be more cost-effective and environmentally sustainable in comparison to copper coils. All in all, opting for aluminum coils for HVAC condenser coils is a viable and advantageous choice.

- Q: Are aluminum coils suitable for pharmaceutical vial caps?

- Pharmaceutical vial caps can indeed be made from aluminum coils. When it comes to pharmaceutical packaging, aluminum is highly favored thanks to its exceptional barrier properties. These properties effectively shield the vials' contents from moisture, oxygen, and other harmful substances. Aluminum coils can be easily molded into caps of various sizes and shapes, accommodating different types of vials. Another advantage is that aluminum is a lightweight material, which makes transportation and handling hassle-free. Additionally, aluminum is resistant to corrosion, ensuring that the vial caps remain intact throughout storage and usage. In summary, due to their barrier properties, versatility, and durability, aluminum coils are a suitable option for pharmaceutical vial caps.

- Q: Is it possible to create a flowerpot using an aluminum coil?

- <p>Yes, you can use an aluminum coil to make a flowerpot. Aluminum is lightweight, durable, and can be easily shaped, making it a suitable material for crafting flowerpots. To create a flowerpot, you would need to cut the coil to the desired size, shape it into a pot form, and possibly add drainage holes. Ensure the aluminum is cleaned and treated to prevent any potential harm to the plants due to chemical reactions with the soil.</p>

- Q: i am thnking of building my own aluminum john boat and using the propulsion from a jetski to power it, i was wondering if anyone had taken on a project like this and had a few pieces of advice to offer while i am still in the planning stages. the biggest concern i have right now involves the tunnel for the intake, should i use the original fiberglass from the jetski or build up a tunnel out of aluminum for it?

- I have built from both aluminum and steel. It sounds interesting and I would suggest using the fiberglass set up as all the clearances are set so you could just bond it to the aluminum. You can bond a fiberglass structure to aluminum by both bolting it up and bedding it down with something like 3M 5200.

Send your message to us

Aluminum Coils Price - PE/PVDF Painted Aluminum Coil for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords