Aluminum Roofing Coil - PVDF Painted Aluminum Coil Competitive Price and Best Manufacturer and Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of PVDF Painted Aluminum Coil Competitive Price and BEST Manufacture and factor

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of PVDF Painted Aluminum Coil Competitive Price and BEST Manufacture and factor

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of PVDF Painted Aluminum Coil Competitive Price and BEST Manufacture and factor

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

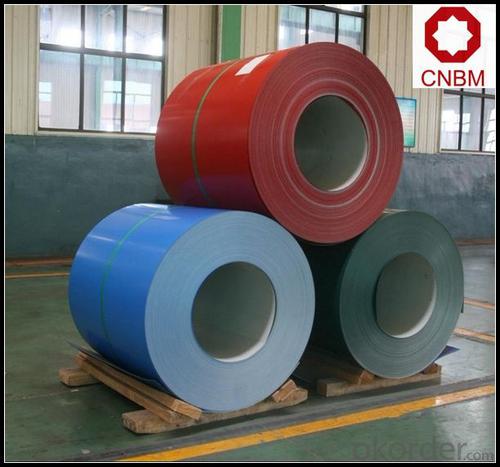

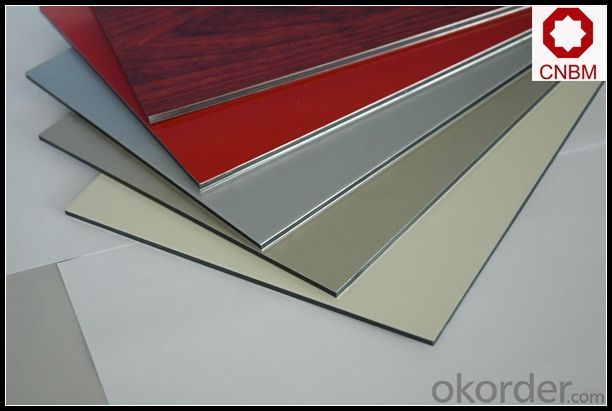

5. Image of PVDF Painted Aluminum Coil Competitive Price and BEST Manufacture and factor

6. Package and shipping of ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What happens when you mix Aluminum (or magnesium) with calcium carbonate? Can you write a chemical equation please?

- Neither aluminium nor magnesium will react with calcium carbonate. The suggested displacement reaction would only occur if aluminium or magnesium were more electropositive than calcium. Electrode potential data shows that this is not the case. Calcium is more electropositive than both aluminium and magnesium.

- Q: This question asks for the method to cut an aluminum coil into smaller sections.

- <p>To cut an aluminum coil into smaller pieces, you can use a metal cutting band saw, which is designed for cutting metal materials. Ensure the blade is sharp and the speed is appropriate for aluminum. Secure the coil in a vice or a cutting table to prevent movement during cutting. Wear safety goggles and gloves. Turn on the saw and slowly feed the coil through the blade, applying steady pressure. After cutting, smooth any rough edges with a file or sandpaper. Always follow safety precautions and manufacturer's instructions for your specific cutting tool.</p>

- Q: Can aluminum coils be used for architectural facades?

- Indeed, architectural facades can make use of aluminum coils. The lightweight, durable, and versatile nature of aluminum makes it a favored option for such purposes. With the ability to mold aluminum coils into diverse shapes and sizes, one can create unique and visually pleasing facades. Furthermore, aluminum demonstrates resistance to corrosion, rendering it suitable for outdoor use. Moreover, aluminum allows for easy coating or finishing, enabling an improved aesthetic appeal and protection against environmental factors. All in all, aluminum coils offer an economically viable and environmentally friendly alternative for architectural facades.

- Q: What are the acoustic properties of buildings using aluminum coils?

- Buildings using aluminum coils for their acoustic properties can benefit from enhanced sound insulation and noise reduction. Aluminum coils have good sound absorption capabilities, helping to minimize the transmission of sound waves through walls, ceilings, and other surfaces. Additionally, the lightweight nature of aluminum coils allows for easy installation and can help reduce the overall weight of the building structure.

- Q: How are aluminum coils protected against scratches and damage?

- Aluminum coils can be safeguarded from scratches and damage through various methods. One effective approach involves applying a protective coating or film to the surface of the coil, serving as a barrier against potential sources of damage like abrasion or impact. Another means of protection is through the utilization of coil coating. This involves cleaning, pre-treating, and coating the coil with a layer of protective paint or resin. This not only enhances the coil's appearance but also provides a safeguard against scratches and other types of damage. Moreover, during the manufacturing and handling process, aluminum coils are frequently wrapped or packaged using materials that offer cushioning and protection. This prevents scratches or dents that may occur during transportation or storage. Lastly, proper handling and storage practices are crucial in preserving the integrity of aluminum coils. Exercising care when handling the coils, employing suitable equipment and techniques, can effectively minimize the risk of scratching or causing other damage. Storing the coils in a clean and dry environment further aids in preventing potential harm. In conclusion, the combination of protective coatings, coil coating processes, proper handling, and storage practices ensures that aluminum coils remain well-protected from scratches and damage, thus maintaining their quality and appearance.

- Q: Can aluminum coils be used for electrical enclosures?

- Yes, aluminum coils can be used for electrical enclosures. Aluminum is a commonly used material for enclosures due to its excellent conductivity, lightweight nature, and resistance to corrosion. It provides good protection against electromagnetic interference and can effectively dissipate heat. Additionally, aluminum coils can be easily formed and fabricated into various shapes and sizes, making them suitable for electrical enclosures in different applications.

- Q: How do aluminum coils contribute to the electrical conductivity of products?

- Aluminum coils contribute to the electrical conductivity of products due to their excellent electrical conductivity property. When electrical current is passed through aluminum coils, they allow the flow of electrons with minimal resistance, enabling efficient transmission of electricity and enhancing the overall conductivity of the product.

- Q: I am a college student living in a private apartment and I use up lots of aluminium foils to cook and eat. I use aluminium foils as plates because I am too lazy to clean plates. I want to know how environment-unfriendly i am for doing so. How bad am I compared to the guy who keeps on drinking from cans without recycling them?

- Aluminium foil is less than 0.2mm thick but typically 0.02mm so a piece 300mm x 100mm has a total volume of 3 x 1 x 2 x 10^2 mm^3 that is 600 mm^3 The density of Al is 2700 kg/m^3 so the mass of your foil is 2700 x 600 /10^9 kg = 0.00162 kg = 1.62 g Modern aluminium cans weigh about 15g I take it you aren't studying either physics or mathematics or you would easily have workd it out!

- Q: Can aluminum coils be used for insulation purposes?

- No, aluminum coils cannot be used for insulation purposes as aluminum is a conductor of heat and does not possess insulating properties.

Send your message to us

Aluminum Roofing Coil - PVDF Painted Aluminum Coil Competitive Price and Best Manufacturer and Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords