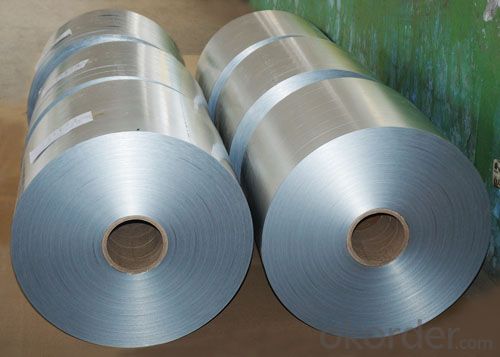

Aluminum in Coil Form - 5052 Temper H32 0.8mm to 1mm Thick 1000mm Width Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

5052 Temper H32 0.8mm 1mm Thick 1000mm Width Aluminum Coil

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above

3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment.

6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications.

Description

item | 1050 1060 1100 3003 Aluminum coil | |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc | |

Material | 1060,1050,1100 3003,3103,3004,3005,3105 5052, 5454,5754 | |

Size | Thickness | 0.5mm-3.5mm |

Width | 800-1500mm | |

Weight/Roll | About 1.5MT/3MT | |

Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. | |

Surface | Bright, polished, hair line, brush, checkered, embossed, etc | |

Trade terms | Price term | ,FOB, CNF, CIF, etc |

Payment Term | TT,L/C | |

MOQ | 2MT | |

20 GP Capacity | About 20-25MT | |

Delivery time | 1.The products will delivery immediately after receiving the payment. 2.According to the order quantity, prompt delivery. | |

Export to | Ireland,Singapore,Indonesia,Ukraine,Spain,Canada,USA,Brazil,Thailand,Korea,Iran,India,Egypt,Kuwait, Oman,Viet Nam, South Africa, Dubai, Russia, etc | |

Package | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | |

Application | 1)Further making utensil.2)Solar reflective film3)The appearance of the building4)Interior decorating:ceilings,walls,etc.5)Furniture cabinets6)Elevator decoraction7)Signs,nameplate,bags making.8)Decoration inside and outside the car9)Household appliances:refrigerators,microwave ovens,audio equipment,etc.10)The consumer electronics:mobile phones,digital cameras,MP3,etc. | |

- Q: Why is the hard drive made of aluminum? Why is steel not used, despite being cheaper?

- Aluminum does not rust or corrode under normal circumstances and if anodized it is already oxidized and covered with the second hardest naturally occurring material on earth alumina , in its gem form it is known as ruby or sapphire.

- Q: Please tell me the the size of the piece of aluminum that you give the weight messurements.

- aluminums gravity is 2.70 and weighs 1.423 troy ozs per cubic inch a note specific gravity of any metal or alloy is weight in grams of one cubic centimeter. also most metals use troy weights and to find troy weight of one cubic inch of any metal or alloy multiply specific gravity by a constant of 0.52686

- Q: How are aluminum coils protected against chemical exposure?

- Various methods are employed to safeguard aluminum coils from chemical exposure. One prevalent approach involves applying a protective coating or finish to the coil's surface. This coating serves as a barrier, shielding the aluminum from potentially harmful chemicals and preventing direct contact and corrosion. Another technique is anodization, whereby the aluminum surface is treated electrolytically to create a layer of oxide. This oxide layer not only provides excellent resistance against chemical exposure but also enhances the overall durability of the coils. Anodized aluminum coils find extensive use in industries like construction, automotive, and aerospace, where chemical resistance is of utmost importance. Additionally, aluminum coils can be safeguarded by employing specific alloys designed to withstand chemical corrosion. These alloys incorporate additional elements, such as copper or magnesium, which bolster the aluminum's resistance to chemical attack. By carefully selecting the appropriate alloy composition, manufacturers can ensure that the aluminum coils are better equipped to endure chemical exposure. In summary, protecting aluminum coils from chemical exposure necessitates a combination of protective coatings, anodization, and the use of corrosion-resistant alloys. These measures play a vital role in prolonging the lifespan of the coils and maintaining their performance even in harsh chemical environments.

- Q: Are aluminum coils suitable for architectural roofing systems?

- Yes, aluminum coils are suitable for architectural roofing systems. Aluminum is a popular choice for roofing due to its numerous advantages. Firstly, aluminum is lightweight, which makes it easier to handle during installation and reduces the load on the building's structure. Additionally, aluminum is highly durable and corrosion-resistant, making it a long-lasting option for architectural roofing systems. It also has excellent thermal properties, reflecting heat and reducing energy consumption. Moreover, aluminum coils can be easily shaped and formed into various profiles and designs, allowing for flexibility in architectural styles. Lastly, aluminum is a sustainable material as it is recyclable, making it an environmentally friendly choice for roofing systems. Overall, aluminum coils are a suitable and practical option for architectural roofing systems, providing durability, versatility, and energy efficiency.

- Q: Can aluminum coils be used for electrical conductors?

- Yes, aluminum coils can be used for electrical conductors. Aluminum is a highly conductive metal that is commonly used in electrical applications. It has a high electrical conductivity, second only to copper, making it a suitable material for conducting electricity. Aluminum coils are often used in various electrical devices and installations, such as transformers, motors, generators, and power transmission lines.

- Q: Can aluminum coils be used in automotive body panels?

- Automotive body panels can indeed utilize aluminum coils. Being both lightweight and corrosion-resistant, aluminum proves to be a suitable material for automotive purposes. The employment of aluminum coils in body panels yields numerous benefits, such as enhanced fuel efficiency owing to the reduced vehicle weight, improved handling and maneuverability, and increased durability. Moreover, aluminum boasts high recyclability, rendering it an environmentally conscious alternative for automotive production. Numerous automakers have already begun integrating aluminum coils into their vehicles, and this trend is anticipated to persist as the industry aims for lighter and more environmentally sustainable automobiles.

- Q: What are the potential health hazards associated with the use of old aluminum coils?

- <p>Using old aluminum coils can pose health risks due to potential leaching of aluminum into food or beverages. Long-term exposure to aluminum may lead to cognitive impairments and neurological issues. Additionally, old coils may have accumulated dirt, bacteria, or other contaminants that could cause infections or digestive problems. It's important to regularly inspect and replace aluminum cookware to ensure safety.</p>

- Q: Can aluminum coils be used in electrical or electronic applications?

- Aluminum coils find utility in electrical and electronic applications. This material, known for its high conductivity, offers various advantages over alternatives like copper in coil applications. Their lightweight nature renders aluminum coils appropriate for weight-sensitive applications. Furthermore, they possess excellent thermal conductivity, ensuring efficient dissipation of heat. Moreover, aluminum coils exhibit resistance to corrosion, making them durable and suitable for outdoor or high-humidity settings. Nonetheless, it is crucial to acknowledge that aluminum's electrical conductivity is lower than that of copper. Hence, the coil's design and dimensions must be meticulously considered to ensure optimal performance.

- Q: Are there any safety concerns when handling aluminum coils?

- Yes, there are safety concerns when handling aluminum coils. Aluminum coils can be sharp and may cause cuts or injuries if mishandled. Additionally, aluminum coils may contain sharp edges or burrs which can pose a risk of injury. It is important to handle them with proper protective equipment such as gloves and ensure safe lifting techniques to avoid any accidents.

- Q: Is it possible to utilize a magnetic stirrer to determine the magnetic characteristics of an aluminum coil?

- <p>No, you cannot use a magnetic stirrer to test the magnetic properties of an aluminum coil. Aluminum is a non-magnetic material, meaning it does not respond to magnetic fields in the way magnetic materials like iron, nickel, or cobalt do. A magnetic stirrer operates by creating a rotating magnetic field to stir substances, but since aluminum is non-magnetic, it will not be affected by the stirrer's field. To test magnetic properties, you would need to use materials that are ferromagnetic or paramagnetic, or employ other methods such as a magnetometer for measuring magnetic fields.</p>

Send your message to us

Aluminum in Coil Form - 5052 Temper H32 0.8mm to 1mm Thick 1000mm Width Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords