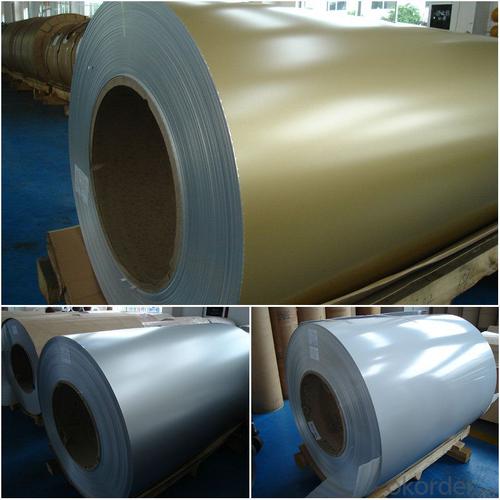

Aluminum Coil Price Per Pound - Color Prepainted Aluminum Panel Sheet 3105h44

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Color coated aluminum magnesium alloy Al-Mn

First, the raw materials:

Al-Mn-Mg aluminum alloy is in generalbased on the addition of manganese and magnesium components, and its productsthan the average tensile strength and elongation strength aluminum, doubled,and its corrosion resistance to oxidation has been further enhanced in Metalindustry is known as rust aluminum. Therefore, Al-Mn-Mg alloy 3004 with arust-proof characteristics and high strength, wide range of uses.

Second,the Al-Mn-Mg alloys the characteristics of color coated aluminum

Colorcoated aluminum magnesium alloy Al-Mn alloy is used for the 3004 state of theAl-Mn-Mg aluminum alloy substrate, after de-ester, cleaning, passivation layerprocessing, and then painting on this basis, the international most advancedlevel of KANAR500 and HYLAR5000 Series Fluorocarbon (PVDF) resin coating, thecolor coated aluminum manganese alloy known international companies use theU.S. PPG, Sweden and the United States Weishi Bo Beca companies paint company,its products by the natural light exposure, Florida testing, with more than 20years of weathering quality assurance. Color coated aluminum magnesium alloyAl-Mn advantages of raw materials, its products have a high strength, corrosionresistance, high weather resistance and other characteristics, and according totheir own customers were asked to choose a different color palette, you cancolor integration, can co-exist to gorgeous effect.

Third,Al-Mn-Mg alloys the use of color coated aluminum

Ourcompany specializes in aluminum color coated aluminum manganese alloy has beenwidely used in large factories, exhibition halls, stadiums, airports, trainstation roof and ceiling decorative envelope system board. Thickness of thealuminum can choose different color coated aluminum magnesium alloy ofmanganese, by cutting, pressing, punching, bending and other follow-up moldingprocess for large span, the larger the overall roof, wall decorative panelsused in construction; You can also cut into small panels by bending, stampingmold, etc., for indoor decorative roof plate; also with polyurethane foam,bonded aluminum honeycomb composite construction for energy-saving decorativewall plates.

Fourth,the development prospects

As the field of building decoration materials, the continuous improvementrequirements, as poor performance of color coated steel corrosion, rust, yellowrust after a large amount of the deficiency of serious impact on the building'soverall appearance, the urgent need to develop a color plate with bothstrength, but also overcome the shortcomings of color-coated steel, while thereare long-term durability of new materials, building decoration, used inairports, commercial buildings, train stations, subways, hospitals and otherarchitectural decoration. The Al-Mn-color coated aluminum magnesium alloymaterials precisely meet these requirements, with the expanding domesticdemand, strengthen public infrastructure under the principle of color coatedaluminum magnesium alloy of manganese will become an increasingly widespreaduse of aluminum, a good prospect.

Embossed color coatedaluminum coil

the company can produce the aluminum coil pattern are: classic orange peel pattern,and variation orange peel pattern (also called as bugs’ pattern). Thicknessspecification is 0.2mm ~ 0.6mm, width less than 1600mm. The materials used arefluorocarbon coated aluminum, polyester coated aluminum coil, aluminum roll,light aluminum, brushed aluminum rolls.

By embossing the surface of aluminum coil elegant, streamlined good, solidsense. Embossed aluminum coil aluminum coil can not only increase the thicknessof the aluminum coil thickness of 0.1 ~ 0.25mm. At the same time can enhance thestrength of aluminum coil, stiffness, and does not affect the original surfacelayer of the aluminum coil with the performance.

Embossed aluminum coil, wide range of uses. Mainly used for indoor and outdoordecoration, freezer, refrigerator, decorative aluminum products, bags, centralair conditioning and ventilation nozzles, and mechanical equipment enclosuresand so on. Is a new decorative material.

Thecompany has two production lines embossed aluminum coil: one for the simpleformula: put through Unwinder mechanical embossing roll winder windingembossed, convenient and quick. Another is the compound: that is embosseddirectly into the device placed in the coating line, coating and embossingsynchronization, when the coating needs of embossed aluminum coil, through thehydraulic transmission, the embossing machine, under the pressure rollerengagement, aluminum coating line directly in the embossing roll, fast, lowcost, no turnover.

Thickness range

0.2mm—0.6mm

Width range

800mm—1590mm

Technical parameters

Aluminum thickness | Coating thickness | MEK | T-bend | Impact | Adhesion | Pencil hardness | Boiling water proof |

0.20-0.60mm | ≥18±1um | ≥100times | ≤3T | 50kg.cm | 0grade | ≥HB | no change within 2 hours |

Performance and Application

Embossed aluminum coil for roofing is coatedwith high-performance polyester paints. And its each performance index is up toor exceeds the national standard. With its glorious colors, little chromatism,strong impact and easy machinability, the product serves as a premium materialin roofing, electric appliances, etc.

Export sea worthy packing,coilOD and through coil ID covered with water proof polythene film to avoidcondensation and white rusting,over the polythene film the coils covered withhard cardboard.Coils should be place on wooden pallets.Coils ID contain hardinner cardboard sleeve.

Used for manufacture decorative materials, such as aluminum veneers, ACP aluminum composite panels, honeycomb panels, aluminum roofing, lighting decoration, household electrical appliances, food package(such as pop can cover and ring-pull),and furniture etc.:

1) Exterior applications: wall cladding, facades, roofs and canopies, tunnels, column covers or renovations;

2) Interior applications: wall cladding, ceilings, bathrooms, kitchens and balconies;

3) Advertisement and market applications: display platforms, signboards, fascias and shop fronts;

4) Transport and industrial applications

- Q: Can aluminum coils be used in the production of kitchen utensils?

- Kitchen utensils can indeed incorporate aluminum coils in their production. Aluminum is a favored material for kitchen utensils owing to its lightweight nature, durability, and ability to conduct heat. Aluminum coils are effortlessly malleable, allowing them to take on various forms and designs for utensils like pots, pans, baking trays, and even cutlery. Moreover, aluminum possesses resistance against corrosion, making it a suitable choice for contact with food and liquids. Nevertheless, it is essential to keep in mind that aluminum utensils may require a non-stick coating or a protective layer to prevent any adverse reactions with acidic or alkaline foods. Ultimately, owing to their adaptability and practicality, aluminum coils are extensively employed in the production of kitchen utensils.

- Q: Explain how aluminum coils function to shield against electromagnetic interference.

- <p>Aluminum coils protect against electromagnetic interference (EMI) through a process known as electromagnetic shielding. Aluminum, being a conductive material, can reflect and absorb EMI, preventing it from penetrating the protected area. When an aluminum coil is used as a shield, it creates an electric field that interacts with the EMI, either reflecting the interference back or absorbing it, thus reducing its impact on sensitive electronic equipment. The high conductivity of aluminum also allows it to distribute the EMI evenly across its surface, minimizing the effect of any single point of entry. This shielding is crucial in various applications, such as in electronic devices and communication systems, to ensure reliable performance and data integrity.</p>

- Q: A nitrate is added with sodium hydroxide, then a piece of aluminum foil. After warming the mixture, ammonia gas is released.A source tells me that aluminum reduces nitrate ion into the ammonium ion. How is this done?

- Aluminum is an active metal and wants to be ionized. Al -- Al(3+) + 3e(-) ?n basic media, tetrahydroxoaluminate complex will be formed: Al(3+) + 4OH(-) -- Al(OH)4(-) ======================================... Al + 4OH(-) -- Al(OH)4(-) + 3e(-) Nitrate is reduced to ammonia in basic media, ammonium in acidic media: N(5+) + 8e(-) -- N(3-) NO3(-) + 8e(-) + 10H(+) -- NH4(+) + 3H2O in basic media, we add base (OH-) to both sides: NO3(-) + 8e(-) + 11OH(-) + 10H(+) -- NH4(+) + 3H2O + 11OH(-) NO3(-) + 8e(-) + OH(-) + 10H2O --- NH3 + 4H2O + 10OH(-) ======================================... NO3(-) + 8e(-)+ 6H2O -- NH3 + 9OH(-) Now, to the balancing of these two redox half reactions: Al + 4OH(-) -- Al(OH)4(-) + 3e(-) NO3(-) + 8e(-)+ 6H2O -- NH3 + 9OH(-) ============================= 8Al + 32OH(-) -- 8Al(OH)4(-) + 24e(-) 3NO3(-) + 24e(-) + 18H2O -- 3NH3 + 27OH(-) ================================== 8Al + 3NO3(-) + 32OH(-) + 18H2O -- 8Al(OH)4(-) + 3NH3 + 27OH(-) //////////////////////////////////////... 8Al + 3NO3(-) + 5OH(-) + 18H2O -- 8Al(OH)4(-) + 3NH3 Hope this helps.

- Q: Are there any specific maintenance requirements for aluminum coils?

- Yes, there are specific maintenance requirements for aluminum coils. Aluminum coils are commonly used in HVAC systems and require regular cleaning and maintenance to ensure optimal performance and longevity. Some of the maintenance requirements for aluminum coils include: 1. Cleaning: Regular cleaning of aluminum coils is necessary to prevent the buildup of dirt, dust, and other contaminants. This can be done using a soft brush or a vacuum cleaner with a brush attachment. It is important to clean both the fins and the surface of the coils to ensure proper airflow. 2. Inspection: Regular inspection of aluminum coils is essential to identify any signs of damage or corrosion. Look for any bent fins, leaks, or signs of wear and tear. If any issues are detected, they should be addressed immediately to prevent further damage. 3. Coil Protection: Applying a protective coating to aluminum coils can help prevent corrosion and extend their lifespan. There are various coatings available in the market specifically designed for aluminum coils, which can provide an additional layer of protection against environmental factors. 4. Air Filter Maintenance: The air filters in HVAC systems play a crucial role in maintaining the cleanliness of the coils. It is important to regularly clean or replace the air filters to prevent the accumulation of dust and debris on the coils. Clogged filters can restrict airflow and reduce the efficiency of the system. 5. Regular Maintenance Schedule: Creating a regular maintenance schedule is essential to ensure that all necessary maintenance tasks are performed on time. This can include cleaning, inspection, and any other specific requirements recommended by the manufacturer. It is important to consult the manufacturer's guidelines and recommendations for specific maintenance requirements for aluminum coils, as they may vary depending on the type of system and application. Following these maintenance requirements can help ensure that aluminum coils function efficiently and have a longer lifespan.

- Q: What are the necessary safety measures to take when handling aluminum oxide coated aluminum coils?

- <p>When working with aluminum oxide coating on aluminum coils, it's crucial to follow safety precautions. Always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a dust mask to prevent inhalation of dust particles. Ensure proper ventilation to avoid dust accumulation. Handle the material carefully to prevent any skin contact with the coating. Keep the area clean and free from any flammable materials to avoid fire hazards. Be aware of the specific health risks associated with aluminum oxide exposure, and follow the manufacturer's guidelines for safe handling. Regularly inspect equipment for any signs of wear or damage that could lead to accidents.</p>

- Q: I'm having trouble with another chem problemAluminum sulfide reacts w/water to form aluminum hydroxide and hydrogen sulfide. Write the balanced chemical equation for this reaction and find how many grams of aluminum hydroxide are obtained from 14.2 g of aluminum sulfide.I already found the balanced equation but I need help on finding how many grams of aluminum hydroxide are obtained from 14.2 g of aluminum sulfide. Can someone please explain how it's done?

- No way!! because of the fact inspite of the bat, the helmet and the shin guards the undergo is plenty larger than a human and is going to basically get mad from the bat and kill you. Nope $800,000 isn't something for that!

- Q: Why does the hollow aluminium rolling shutter door fall off for a long time?

- The series of HO profiles is heated by Doyle's Aluminum Alloy bar by extrusion forming production, use the 6063 Aluminum Alloy material, has excellent plasticity, corrosion resistance, toughness, easy polishing, film.

- Q: Can aluminum coils be painted or coated with other materials?

- Yes, aluminum coils can be painted or coated with other materials. This process is commonly done to enhance the appearance, protect against corrosion, or improve thermal insulation properties of the coils.

- Q: Are there any recycling programs for used aluminum coils?

- Yes, there are recycling programs available for used aluminum coils. Many recycling centers and scrap yards accept aluminum coils for recycling, as aluminum is a highly recyclable material.

- Q: Are aluminum coils suitable for interior design applications?

- Yes, aluminum coils are suitable for interior design applications. Aluminum is a versatile material that offers a wide range of benefits for interior design projects. Firstly, aluminum is lightweight, making it easy to handle and install. This is especially advantageous for projects that require large-scale installations or suspended ceilings. Additionally, aluminum coils are highly durable and resistant to corrosion, ensuring their longevity and making them suitable for high-traffic areas. Furthermore, aluminum can be easily customized and shaped to meet specific design requirements, allowing for endless design possibilities. The material is also available in a variety of finishes, such as brushed, polished, or anodized, which can enhance the aesthetic appeal of any interior space. Moreover, aluminum is a sustainable and eco-friendly option, as it is easily recyclable and has a low carbon footprint compared to other materials. Overall, aluminum coils are a practical and aesthetically pleasing choice for interior design applications.

Send your message to us

Aluminum Coil Price Per Pound - Color Prepainted Aluminum Panel Sheet 3105h44

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords