7075 PE/PVDF Coated Aluminum Coils Mill Finish

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

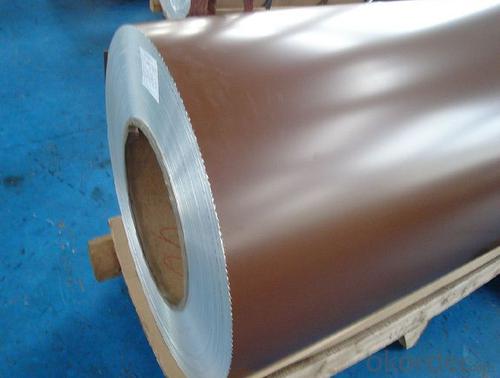

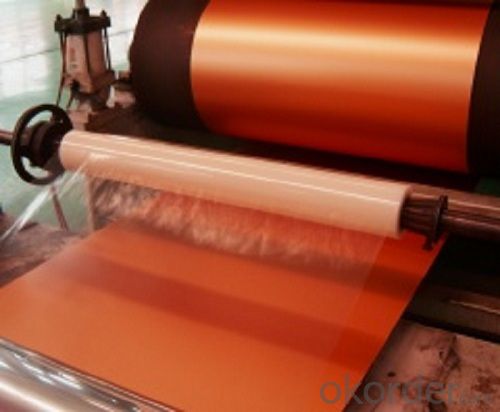

PE/PVDF Coated Aluminum Coil Mill Finish

l Product Introduction

Coated aluminum coils are widely applied to aluminum ceiling, roofing, fireproof roller shutter, doors, wall panel, facade cladding, etc.

l Product Specification:

| PE/PVDF coated aluminum coil | material 1060/3003/3004/3105 |

| painting Thickness | Single-coated ( 4-20 microns ); double-coated ( 25-28 micron ); 3 -coated ( 35-38 micron ) |

| width | within 1660mm |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advanced payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Color coated aluminium coil is one of the popular product in the market of CNBM. With advanced technology and equipment, CNBM has sold its hight quality color coated aluminium coil to the world.

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: Why are the aluminum coils sticky after annealing?

- There is oil or the annealing time is too long!

- Q: I have found many articles claiming that the aluminum content in soy (baby) formula is very high.What I am wondering is- does regular old soy milk for adult consumption also have very high aluminum content?I am extensively researching all possible ways to relieve my 14 month olds terrible constipation. He is not allergic to milk- he was on a milk-based formula. We VERY slowly switched over to whole cow's milk- which turned out to once again be terribly constipating. It was suggested I give lactose-free milk a try- which has seemed to help a little bit- it was working OK for a few days- but he did have quit the hard (and painful) bowel movement a couple days ago. We are trying other options- juices, he's active, we are trying to get enough fiber into this picky eater's diet. I am just researching the possibility of soy milk if this problem persists.I am not willing to give it to him if the aluminum content is even a small possibility. I am not finding much info about adult soy milk. Anyone??

- Soy is known to have a lot of hormones in it. Not good for a growing baby. A study even showed that female infants that were fed soy formula went into puberty a lot sooner than girls that were fed breastmilk or regular formula.

- Q: What does 1060 of the 1060 Aluminum rolls stand for?

- Can aluminium rolls be classified into nine categories? One series is the 1060 series, which represents the 1050106010701000 series aluminum plate, also known as pure aluminum. In all the series, the 1000 series belongs to a series with the largest amount of aluminum.

- Q: Aluminum alloy coil quotation = = how much is the price?

- Different alloy materials, different prices, but also with the thickness and width of a direct relationship!

- Q: what properties etc makes us use aluminium as the material behind cans...And why does it have the properties?

- Aluminium only became popular in the sixties. Prior to that it was steel cans. You had to have a church key to open them. Aluminium is cheaper to recycle and make than steel. It always comes down to money and costs.

- Q: What are the different color options for anodized aluminum coils?

- Anodized aluminum coils offer a wide range of color options to choose from. The anodization process involves immersing the aluminum in an electrolyte solution and applying an electric current to create a protective oxide layer on the surface. This oxide layer can be dyed in various colors, allowing for customization and aesthetic enhancement. Some common color options for anodized aluminum coils include silver, black, bronze, gold, copper, and champagne. These colors are achieved by using different dye solutions during the anodization process. Additionally, there are also various shades and finishes available within each color category, providing further versatility and choice. The color options for anodized aluminum coils are not limited to solid colors only. It is also possible to create patterns, gradients, or even custom designs by applying masking techniques or utilizing advanced printing technologies. This allows for even more creative freedom and the ability to match specific branding or design requirements. Furthermore, anodized aluminum coils offer excellent color retention and durability. The anodized oxide layer not only provides protection against corrosion and wear but also acts as a base for the dyed color, resulting in long-lasting and vibrant finishes. In summary, the different color options for anodized aluminum coils are extensive and diverse, ranging from traditional metallic finishes to bold and unique shades. This variety allows for endless possibilities in architectural, industrial, and decorative applications, ensuring that there is a suitable color option for every project.

- Q: This question asks for methods to take care of and preserve aluminum coils, ensuring their longevity and functionality.

- <p>To maintain aluminum coils, follow these steps: Keep them clean by wiping off any dust or debris. Store them in a dry environment to prevent corrosion. Avoid stacking heavy objects on top to prevent deformation. Regularly inspect for any signs of damage or wear. Use appropriate handling equipment to avoid scratches or dents. Apply a protective coating if exposed to harsh conditions. Ensure proper ventilation during storage to prevent condensation. By following these practices, you can prolong the life and maintain the quality of aluminum coils.</p>

- Q: Automotive aluminum coil, using GB H22, what brand, what are the main ingredients?

- 5754-H22 aluminum sheet has the characteristics of medium strength, good corrosion resistance, weldability and easy processing. It is a typical alloy in Al-Mg (mg Al alloy) alloy.

- Q: Aluminum coil area, with aluminum sheet area, how is not the same?

- Direct measurement length and width calculation area of aluminium plate;The aluminum coil can measure the volume of the aluminum coil and then calculate the area by dividing the thickness. You can also measure the mean diameter, calculate the perimeter, multiply the number of laps, the width, and calculate the area.

- Q: How do aluminum coils compare to copper coils?

- Aluminum coils are generally lighter and less expensive than copper coils, but they have lower thermal conductivity and may require larger coil sizes. Copper coils, on the other hand, have superior heat transfer properties, making them more efficient for cooling or heating applications.

Send your message to us

7075 PE/PVDF Coated Aluminum Coils Mill Finish

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords