Aluminum Coil Metal Lowes - Aluminium Foil (HHF, Waterproof Foil) / Aluminum Film from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Foil/ Waterproof foil

1) Alloy | AA1050, AA1060, AA1070, AA1100, AA3003, AA3004, AA3105, AA5005, AA5052, AA8011, AA8079 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum |

7) Coil Inner diameter | 76mm, 152mm, or as required |

2. Application of Aluminum Foil/ Waterproof foil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts.

3. Feature of Aluminum Foil/ Waterproof foil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate of Aluminum Foil/ Waterproof foil:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

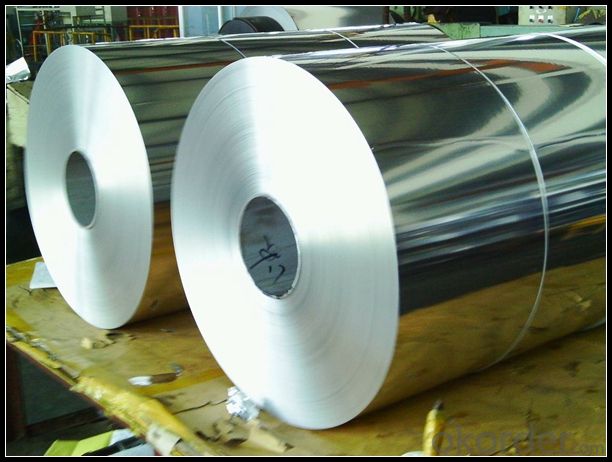

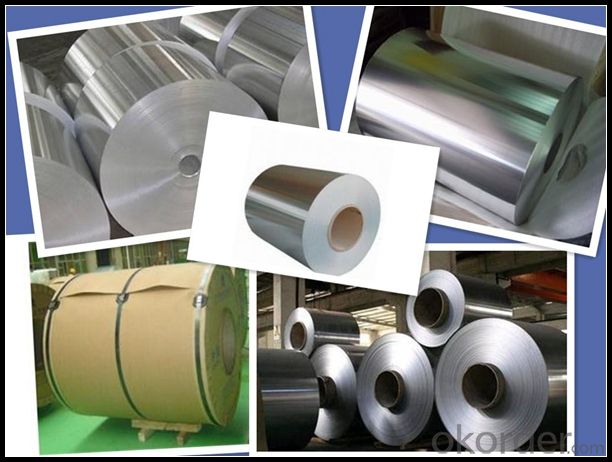

5. Image of Aluminum Foil/ Waterproof foil

6. About Our Company

CNBM International Corp., established in 2004, is the business entity for trade and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 25 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe etc

4)What are your payment terms?

We accept L/C, D/A, D/P, T/T, West Union,etc.

- Q: What are the potential applications of embossed aluminum coils?

- Embossed aluminum coils have a wide range of potential applications due to their unique properties and versatility. Some of the potential applications of embossed aluminum coils include: 1. Decorative purposes: Embossed aluminum coils are commonly used in interior and exterior architectural design applications. They can be used for wall cladding, ceiling panels, decorative facades, and other decorative elements. The embossed patterns on the coils add a visually appealing texture and depth to the surfaces, enhancing the overall aesthetic appeal of the space. 2. Packaging industry: Embossed aluminum coils are widely used in the packaging industry. They can be used for manufacturing packaging materials such as cans, boxes, lids, and closures. The embossed patterns on the coils not only enhance the visual appeal of the packaging but also provide additional strength and rigidity to the structure, making it more durable and resistant to damage. 3. Heat transfer applications: Embossed aluminum coils are also used in heat transfer applications. The embossed patterns on the coils create turbulence in the fluid flow, increasing the heat transfer efficiency. This makes them suitable for use in heat exchangers, evaporators, condensers, and other heat transfer equipment. 4. Automotive industry: Embossed aluminum coils find applications in the automotive industry. They are used in the manufacturing of car body panels, trims, and decorative elements. The embossed patterns on the coils can provide a unique and stylish appearance to the vehicles, making them stand out in the crowd. 5. Electrical industry: Embossed aluminum coils are commonly used in the electrical industry for various applications. They can be used for manufacturing electrical enclosures, switchboards, and control panels. The embossed patterns on the coils improve the structural integrity and provide better protection against external factors such as moisture, dust, and corrosion. 6. Furniture industry: Embossed aluminum coils are also used in the furniture industry. They can be used for manufacturing furniture components such as table tops, cabinet doors, and decorative trims. The embossed patterns on the coils add a touch of elegance and sophistication to the furniture, making it visually appealing. Overall, embossed aluminum coils have a wide range of potential applications in various industries, including architecture, packaging, heat transfer, automotive, electrical, and furniture. Their unique properties and versatility make them a preferred choice for many applications where aesthetics, strength, and durability are important.

- Q: Pretty please can someone show me the steps on how to do this one?Calculate the mass in grams of iodine (I2) that will react completely with 43.7 g of aluminum (Al) to form aluminum iodide

- Aluminum Iodide is AlI3 - one aluminum atom bonded to three Iodine atoms. Look up the atomic weight of Aluminum. Look up the atomic weight of Iodine. Al / 43.7g =3 X Iodine / mass Mass of Iodine required = 43.7 X Atomic weight of Iodine X 3 / Atomic weight of Aluminum

- Q: Can aluminum coils be used in transformer windings?

- Transformer windings can indeed utilize aluminum coils. Aluminum is a widely employed material for transformer windings because its resistivity is low, conductivity is high, and it is cost-effective compared to copper. It possesses numerous advantages, including being lighter in weight, having superior thermal conductivity, and yielding lower manufacturing expenses. However, there are certain considerations to keep in mind when using aluminum coils in transformer windings. For instance, a larger cross-sectional area is necessary to compensate for its lower conductivity when compared to copper. Furthermore, special techniques may be required to prevent galvanic corrosion when aluminum comes into contact with other metals within the transformer. All in all, aluminum coils can serve as a viable substitute for copper coils in transformer windings, providing benefits in terms of efficiency and cost.

- Q: What does 1060 of the 1060 Aluminum rolls stand for?

- At present, most of the circulation in the market is 1050 and 1060 series. 1000 series aluminium plate to determine the minimum aluminum content in this series according to the amount of the last two Arabia figures, such as the 1050 series of the last two Arabia number 50, according to the international brand naming principles, content must reach 99.5% to the top for qualified products. China's aluminum alloy technology standard (gB/T3880-2006) is also clearly defined, 1050 aluminum content of 99.5%., the same reason, 1060 series aluminum plate aluminum content must reach more than 99.6%.

- Q: My favorite deodorant contains aluminum. It smells really good and it works really well.My mom doesn't like me using it because it contains aluminum.So I got aluminum free. It doesn't smell at all (I can't seem to find fragrant aluminum free deodorant) and it doesn't work as well, for some reason.I want to keep using the one with aluminum, but will it be harmful to me in the future?

- aluminum is an antiperspirant so it stops you from sweating. if you don't have a wetness problem you could just use regular deodorant check out Jason's natural products or kiss my face cosmetics

- Q: What are the various applications and purposes for which aluminum coils are utilized?

- <p>Aluminum coils have a wide range of applications due to their lightweight, corrosion resistance, and malleability. They are commonly used in construction for roofing and siding, in the automotive industry for car parts and body panels, in the packaging industry for cans and foils, and in electrical applications for wiring and transformers. Aluminum coils are also used in the manufacturing of heat exchangers, cooking utensils, and various consumer products. Their versatility makes them an essential material in many industries.</p>

- Q: Why does the hollow aluminium rolling shutter door fall off for a long time?

- The series of HO profiles is heated by Doyle's Aluminum Alloy bar by extrusion forming production, use the 6063 Aluminum Alloy material, has excellent plasticity, corrosion resistance, toughness, easy polishing, film. Aluminum Alloy thermal cooling fast, excellent seismic performance, the design of hollow base not only greatly reduce the heat conduction, but also effectively reduces the acoustic resonance effect, suitable for hot summer and warm winter area and some noise pollution area.

- Q: What is the primary function or use of a spring steel wire coil?

- <p>A spring steel wire coil is primarily used for its high elasticity and strength. It is designed to return to its original shape after being deformed, which makes it ideal for applications requiring resilience and durability. Common uses include the manufacturing of various types of springs, such as compression springs, torsion springs, and extension springs, found in automotive suspensions, mechanical devices, and industrial equipment. The coil's properties also make it suitable for applications in furniture, electronics, and other industries where a reliable and consistent force is needed.</p>

- Q: Can aluminum coils be recycled multiple times without losing their properties?

- Aluminum coils possess the remarkable ability to be recycled countless times while retaining their inherent characteristics. With aluminum being an exceptionally recyclable substance, the process of recycling coils entails melting the metal to its liquid state and subsequently reshaping it into fresh coils or other aluminum products. This cycle can be perpetually repeated without compromising the aluminum's quality or attributes. Remarkably, recycling aluminum consumes a mere 5% of the energy required for manufacturing new aluminum from raw materials, rendering it an environmentally conscious choice. Moreover, the properties of aluminum, including its strength, durability, and resistance to corrosion, remain unaltered throughout the recycling procedure, ensuring that the recycled coils can be employed for numerous applications just like their original counterparts. Consequently, recycling aluminum coils not only conserves valuable resources but also contributes to waste reduction and fosters sustainability.

- Q: Is it possible to utilize a grinder for cutting aluminum coils?

- <p>Yes, you can use a grinder to cut aluminum coils, but it's important to use the right type of grinder and accessories. An angle grinder with a cutting wheel or a metal cutting disc is suitable for this task. Ensure the grinder is equipped with a safety guard and that you're wearing appropriate safety gear, such as goggles and gloves. Be cautious as aluminum can be slippery and the grinder can generate a lot of heat, which may require frequent cooling to prevent the disc from burning out. It's also advisable to work in a well-ventilated area due to the fine particles produced during cutting.</p>

Send your message to us

Aluminum Coil Metal Lowes - Aluminium Foil (HHF, Waterproof Foil) / Aluminum Film from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords