7075 Aluminum Coil - Aluminium Foil / Aluminum Film Supplied from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Foil

1) Alloy | AA1050, AA1060, AA1070, AA1100, AA3003, AA3004, AA3105, AA5005, AA5052, AA8011, AA8079 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum |

7) Coil Inner diameter | 76mm, 152mm, or as required |

2. Application of Aluminum Foil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts.

3. Feature of Aluminum Foil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate of Aluminum Foil:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

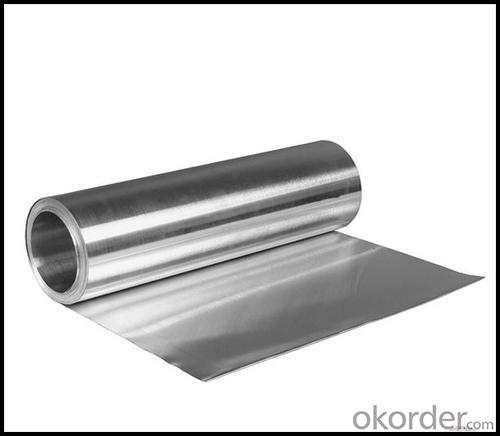

5. Image of Aluminum Foil

6. About Our Company

CNBM International Corp., established in 2004, is the business entity for trade and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 30 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

4)What are your payment terms?

We accept L/C, D/A, D/P, T/T, West Union,etc.

- Q: Can aluminum coils be used in cryogenic applications?

- Indeed, cryogenic applications can utilize aluminum coils. Highly regarded for its remarkable thermal conductivity, aluminum proves to be an appropriate substance for heat transfer in environments with low temperatures. Moreover, aluminum exhibits a minimal coefficient of thermal expansion, enabling it to endure the drastic temperature fluctuations inherent in cryogenic applications while avoiding notable alterations in dimensions. Nevertheless, it is important to acknowledge that aluminum coils might necessitate specific design or treatment to guarantee their resilience against exceedingly frigid temperatures and mitigate any potential concerns like brittleness or embrittlement.

- Q: This question is asking for a comparison of various types of aluminum coils, highlighting their unique characteristics and uses.

- <p>Aluminum coils are differentiated by their thickness, alloy composition, surface treatment, and temper. Common types include 1000 series coils with high purity, 3000 series known for formability, 5000 series for corrosion resistance, and 6000 series for strength. Thickness varies from thin gauges used in packaging to thick ones for construction. Surface treatments can include anodizing, painting, or lacquering for enhanced properties. Temper refers to the hardness and strength, with 'H' for hard and 'O' for soft tempers. Each type serves specific industries, such as automotive, aerospace, construction, and packaging.</p>

- Q: What are the disadvantages of using aluminum coils?

- There are several disadvantages of using aluminum coils in various applications. Firstly, aluminum coils tend to have a lower heat transfer coefficient compared to other materials like copper. This means that they may not be as efficient in transferring heat, which can negatively impact the performance and energy efficiency of cooling or heating systems. Additionally, aluminum coils are more prone to corrosion compared to copper coils. This is especially true in environments with high humidity or exposure to harsh chemicals. Corrosion can lead to leaks in the coil, reducing its lifespan and potentially causing damage to the system. Another disadvantage of aluminum coils is their relatively lower tensile strength compared to other materials. This means that they may be more susceptible to damage or failure under excessive pressure or stress. This can be a concern in applications where the coils are subject to high pressure or frequent movement. Furthermore, aluminum coils can be more expensive compared to other materials like copper. While aluminum itself is a cheaper material, the manufacturing processes involved in producing aluminum coils and the additional coatings required to improve its performance can increase the overall cost. Lastly, aluminum coils may require more maintenance and cleaning compared to other materials. Due to their tendency to accumulate dust, dirt, and debris more easily, regular cleaning is necessary to maintain their performance and prevent clogging or blockages. Overall, while aluminum coils have their advantages such as being lightweight and resistant to corrosion in certain environments, it is important to consider these disadvantages when choosing the appropriate coil material for specific applications.

- Q: I was told today that taking aluminium inside your body greatly increases the chance of getting alzheimers as they destroy cells. What foods contain aluminium?

- i dont think any foods will contain substantial quantities of aluminium as its not a metal commonly found in bioinorganic chemistry. Aluminium salts could potentially be found in water, also using aluminium pans could potentially lead to aluminium consumption. hope this helps

- Q: I have a diamond back bike with an aluminum frame. will it rust if i ride or put it in the frame? is it bad for the bike?

- Aluminum does not rust, it will oxidize if exposed to the open air if the paint is scratched off. The oxidation will protect against any more damage and is stopped in it's tracks. Other aluminum parts will not rust but the mounting hardware may if it's made from low quality materials. On nuts and bolts you can put some chain oil on the tip of a rag and wipe these parts down every one in a while. On things like cables I use Tri Flow, it lubricates and protects against rust.

- Q: What are the various categories of aluminum coils based on their characteristics and applications?

- <p>Aluminum coils are categorized based on their thickness, alloy composition, surface treatment, and temper. The main types include: 1) Thickness-based: thin gauge, medium gauge, and thick gauge coils. 2) Alloy composition: 1000 series (99% aluminum), 3000 series (aluminum-manganese), 5000 series (aluminum-magnesium), 6000 series (aluminum-silico-magnesium), and 7000 series (aluminum-zinc). 3) Surface treatment: mill finish, anodized, painted, and coated. 4) Temper: O (annealed), H (strain hardened), W (solution heat treated), and T (thermally treated to various strengths). Each type serves specific industries such as construction, automotive, packaging, and aerospace.</p>

- Q: Inquiry about the feasibility of using a laser for cutting aluminum coils.

- <p>Yes, you can use a laser to cut aluminum coils. Laser cutting is a versatile process that can be used on a variety of materials, including aluminum. However, it's important to note that the type of laser and the specific settings should be appropriate for aluminum. Fiber lasers or CO2 lasers are commonly used for metal cutting, including aluminum. The process requires careful control of the laser's power, speed, and focus to achieve clean and precise cuts. Additionally, because aluminum is a reflective metal, special considerations such as the use of a protective cover gas and proper nozzle management are necessary to prevent damage to the laser equipment and to ensure the quality of the cut.</p>

- Q: What are the common problems faced with aluminum coils?

- Aluminum coils encounter various issues that commonly arise. The foremost predicament is corrosion, which poses a significant threat to aluminum coils, especially when they come into contact with moisture. Consequently, rust or other types of corrosion may develop, thereby weakening the coil and impacting its performance. Another prevalent problem is coil damage, which can be easily incurred during handling or transportation. This can result in coils becoming bent or dented, thus compromising their efficiency and lifespan. In severe cases, leaks or cracks may even manifest, leading to the leakage of refrigerant or coolant. Clogging is an additional concern that can manifest in aluminum coils. Over time, dust, dirt, and debris can accumulate on the coil, thereby obstructing airflow and diminishing the coil's efficiency. This can lead to subpar cooling or heating performance, heightened energy consumption, and increased wear and tear on the system. Furthermore, aluminum coils are susceptible to leaks. These leaks may stem from physical damage, corrosion, or manufacturing defects. Once a coil develops a leak, refrigerant or coolant may escape, consequently impacting the overall performance of the HVAC system. Lastly, improper installation or maintenance practices can also give rise to issues with aluminum coils. If the coil is not installed accurately or if regular maintenance is overlooked, problems such as inadequate airflow, inefficient cooling or heating, and heightened energy consumption may occur. To circumvent these common problems, it is imperative to adequately maintain aluminum coils by regularly cleaning them, inspecting for signs of damage or corrosion, and ensuring proper installation and handling. Consistent maintenance and timely repairs can mitigate the occurrence of these problems and guarantee the longevity and efficiency of the aluminum coils.

- Q: What are the different surface finishes for pre-painted aluminum coils?

- Pre-painted aluminum coils offer a variety of surface finishes to enhance their appearance, durability, and resistance to external factors. The most commonly used finish is Polyester (PE), which provides good durability, weather resistance, and color retention. It is available in a wide range of colors and gloss levels. Another popular option is Polyvinylidene Fluoride (PVDF) finish, known for its excellent resistance to weathering, UV radiation, and chemicals. It maintains color and gloss for extended periods, making it ideal for architectural applications. Polyurethane (PU) finish is preferred for its resistance to abrasion, chemicals, and weathering. It offers a smooth and glossy appearance and is available in various colors. PU finish is commonly used in outdoor applications that require high durability. Epoxy (EP) finish is known for its excellent chemical resistance and adhesion. It is often used in industrial applications where corrosion resistance is crucial. It can be combined with other coatings to enhance its performance. Acrylic (AC) finish provides good weather resistance and color retention. It is commonly used in architectural applications where aesthetics and durability are important. Acrylic finish offers a glossy appearance and a wide range of colors. These examples demonstrate the range of surface finishes available for pre-painted aluminum coils. The choice of finish depends on specific requirements, including desired appearance, durability, and resistance to external factors.

- Q: I have a mig welder, and I would like to learn to weld aluminum. I have been told that I must buy an aluminum wire spool gun, because the standard mig wire feeder gun will not work with aluminum wire. I don't understand why my standard wire feeder will not work. It feeds wire just like a spool gun. Why do I need to spend money on a spool gun just to weld aluminum? If a spool gun is truly necessary, where can i find one for a reasonable price? Thanks for your help!

- This Site Might Help You. RE: Is an aluminum wire spool gun really necessary to weld aluminum with my Mig welder? I have a mig welder, and I would like to learn to weld aluminum. I have been told that I must buy an aluminum wire spool gun, because the standard mig wire feeder gun will not work with aluminum wire. I don't understand why my standard wire feeder will not work. It feeds wire just like a...

Send your message to us

7075 Aluminum Coil - Aluminium Foil / Aluminum Film Supplied from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords