Pvc Aluminum Coil - High Quality Aluminum Coil/Aluminum Plate from Chinese Factory

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Coil

1) Alloy | AA1050, AA1060, AA1070, AA1100, AA3003, AA3004, AA3105, AA5005, AA5052, AA8011, AA8079 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum |

7) Coil Inner diameter | 76mm, 152mm, or as required |

2. Application of Aluminum Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts.

3. Feature of Aluminum Coil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificates:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

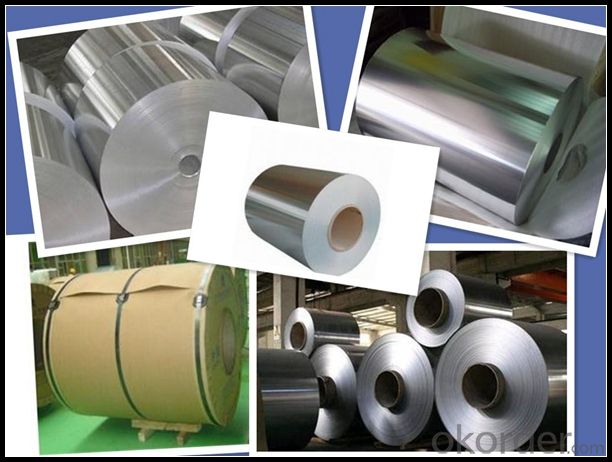

5. Image of Aluminum Coil

6. About Our Company

CNBM International Corp., established in 2004, is the business entity for trade and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 30 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

4)What are your payment terms?

We accept L/C, D/A, D/P, T/T, West Union,etc.

5)What is the MOQ?

3 Tons

- Q: Can aluminum coils be used in the production of aluminum composite walls?

- Aluminum composite walls can utilize aluminum coils for production purposes. To construct these walls, a layer of polyethylene is typically sandwiched between two aluminum sheets. Initially, the aluminum coils undergo processing to transform into flat aluminum sheets, which then function as the outer layers of the composite wall. During the manufacturing process, the coils are unravelled and flattened to achieve the desired width and thickness of the aluminum sheets. These sheets possess superior strength, durability, and resistance to weather conditions, making them an ideal choice for aluminum composite walls. Moreover, the utilization of aluminum coils enables efficient and cost-effective production since they can be easily processed and moulded into the required dimensions.

- Q: What are the differences between aluminum coil 3003h24 and 3a21h14?

- The mechanical property references of rolled plate 3003 H24and 3A21 H14 are as follows: 3003 H24--Rm/MPa≧140-180;Rp0.2/MPa≧115;A(%)≧1-5(thickness 0.2mm-4.5mm)3A12 H14--Rm/MPa≧145-215;A(%)≧6

- Q: Can aluminum coils be used for electrical conductivity purposes?

- Using aluminum coils for electrical conductivity purposes is not possible. Although aluminum is a decent conductor of electricity, it is not appropriate for coils that are specifically intended for electrical conductivity. Aluminum has a higher resistance in comparison to materials like copper or silver, which are frequently used for electrical conductivity purposes. Furthermore, aluminum has a lower melting point than copper, therefore utilizing it in coils for high electrical currents can result in overheating problems. Consequently, it is more typical to use materials such as copper or silver for electrical conductivity purposes, particularly in situations where high conductivity and low resistance are necessary.

- Q: What are the common surface preparation methods for aluminum coils?

- The common surface preparation methods for aluminum coils include cleaning, degreasing, etching, and conversion coating.

- Q: Can aluminum coils be used for food processing equipment?

- Food processing equipment can indeed utilize aluminum coils. The reason behind the popularity of aluminum in this context lies in its remarkable thermal conductivity, resistance to corrosion, and lightweight properties. The food industry heavily relies on aluminum for a variety of applications, including heat exchangers, evaporators, and condensers. Specifically engineered to effectively transfer heat and uphold a consistent temperature, aluminum coils prove to be ideal for food processing equipment that demands precise temperature control. Moreover, aluminum is a non-toxic material, guaranteeing that it does not contaminate the processed food. Consequently, aluminum coils establish themselves as a dependable and secure choice for food processing equipment.

- Q: Why there is always impression and indentation on the backup roller of aluminum coil rolling mill with 4 rollers.

- It is either the external or the bearing problem in designing and installing.

- Q: What are the different coil pattern options for aluminum coils?

- There are several different coil pattern options available for aluminum coils, depending on the specific application and desired aesthetic. Some common coil pattern options include: 1. Stucco Pattern: This pattern features a textured, raised surface that resembles the appearance of stucco. It provides increased durability and a non-slip surface, making it suitable for applications such as flooring or outdoor surfaces. 2. Diamond Pattern: This pattern consists of small diamond-shaped embossed designs, providing a visually appealing and slip-resistant surface. It is commonly used in applications such as stair treads, walkways, and decorative panels. 3. Wood Grain Pattern: This pattern replicates the appearance of natural wood grain, making it an attractive option for various architectural and interior design purposes. It is often used in applications such as wall cladding, ceiling panels, and furniture. 4. Checkered Pattern: Also known as the checker plate pattern, it features a grid of raised diamonds or squares. This pattern offers excellent slip resistance and is commonly used in applications where safety is a priority, such as ramps, industrial flooring, and staircases. 5. Plain Smooth Pattern: This pattern has a smooth, flat surface without any embossed designs or patterns. It is a versatile option suitable for a wide range of applications, including roofing, gutters, and general fabrication. 6. Ribbed Pattern: This pattern consists of parallel lines or ribs running along the length of the coil. It provides added strength and rigidity, making it commonly used in applications such as truck bodies, trailers, and industrial equipment. These are just a few examples of the various coil pattern options available for aluminum coils. The choice of pattern ultimately depends on the specific requirements of the project, such as functionality, durability, and aesthetic preferences.

- Q: Can aluminum coils be formed into different shapes?

- Yes, aluminum coils can be formed into different shapes through various processes such as bending, rolling, or stamping.

- Q: What are the various applications and purposes of aluminum coil in different industries?

- <p>Aluminum coil is widely used in numerous applications due to its lightweight, corrosion resistance, and high strength. It is commonly used in construction for roofing and siding, in the automotive industry for body panels and heat exchangers, and in the packaging industry for food and beverage cans. Aluminum coil is also utilized in electrical applications such as transformers and wiring, and in the manufacturing of everyday items like foil and cookware. Its versatility makes it a popular material in various industries.</p>

- Q: A certain ionic compound is made entirely of aluminum and oxygenWhat is the formula for this compound?

- Aluminium Oxide: Al2O3 The ions: Al3+ .............. O2- When they bond: It is ionic as it takes place by the transfer of electrons from Aluminium(metal) to Oxygen(Non-metal). Hence, the bond is: Al2O3, Aluminium Oxide or alumina.

Send your message to us

Pvc Aluminum Coil - High Quality Aluminum Coil/Aluminum Plate from Chinese Factory

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords