Aluminum Coils for Sale for ACP, Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

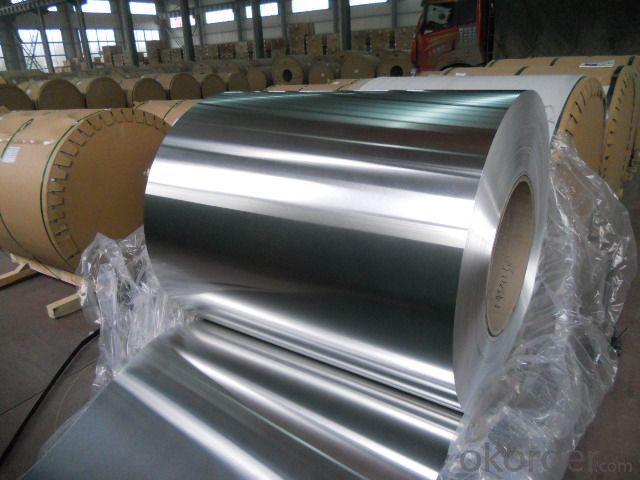

Aluminum Coil for ACP, Aluminum Composite Panel

lProduct Information

| Item | aluminum coil for ACP, Aluminum Composite Panel |

| Alloy Grade | 1100, 3003, 5005 |

| Thickness | 0.3mm~ 3mm |

| Width | 30mm~1850mm |

| Exported Area | USA, UAE, Europe, Asia, Middle East, Africa, South America |

| Min trial order | 2.5 ton each size |

| Tolerance | +2/0mm,thickness tolerance :+0.02/-0.02mm (or according to customers' request) |

lPackaging & Delivery Details

Packaging: Standard seaworthy packing

Delivery: About 25 days after received your advance

lCompany Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building

material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

CNBM has been involved in aluminium products for about a decade. With advanced technology and equipment, our products have been sold to the worldwide including America, Europe, as well as South Asia, etc.

lProduct Images

lCertificates

lFAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

- Q: What are the common sizes and thicknesses of aluminum coils?

- Common sizes and thicknesses of aluminum coils vary depending on the specific application and industry. However, there are some standard sizes and thicknesses that are commonly used across various industries. In terms of size, aluminum coils typically range from around 12 inches to 72 inches in width. This range allows for flexibility in accommodating different production processes and equipment. The length of the coils can vary as well, but it is often in the range of 1000 to 6000 feet. As for thickness, aluminum coils come in various gauges, which are commonly measured in inches or millimeters. The most commonly used thicknesses for aluminum coils are between 0.019 inches (0.48 mm) and 0.125 inches (3.18 mm). These thicknesses are suitable for a wide range of applications, including roofing, construction, automotive, and manufacturing. It is important to note that these are general guidelines, and the specific size and thickness requirements may vary depending on the intended use of the aluminum coils. Additionally, custom sizes and thicknesses can also be manufactured to meet specific project requirements.

- Q: What is the mass of 3.45 moles of Aluminum sulfate?Can u explain how?

- Aluminum sulfate is Al2S3, so you got two atoms of aluminum and three of oxygen. Hence the molar mass of aluminum sulfate is: 2X16 (two times molar mass of oxygen) + 3X32 (three times molar mass of sulfur). Keep in mind that the molar mass of an elements equals its mass number. We have 128 grams per mole or 128 pounds per lb-mol. Since you have 3.45 moles of Al2S3 you just have to do 3.45 times 128 = 441.6 grams

- Q: How are aluminum coils protected against UV exposure during storage?

- Aluminum coils are typically protected against UV exposure during storage through the application of a protective coating or the use of UV-resistant packaging materials. Aluminum coils are highly susceptible to UV degradation, which can result in discoloration, surface damage, and reduced performance. Therefore, manufacturers and distributors take special precautions to ensure that the coils are shielded from harmful UV rays. One common method is the application of a protective coating on the surface of the coils. This coating acts as a barrier between the aluminum material and UV radiation, preventing direct exposure. The coating is typically a specialized paint or lacquer that contains UV inhibitors, which absorb or reflect UV rays, thereby minimizing damage to the coils. This protective layer also helps to preserve the aesthetic appearance of the coils and extend their lifespan. In addition to coatings, aluminum coils can also be stored in UV-resistant packaging materials. These materials are designed to block or absorb UV radiation, effectively creating a shield around the coils. Common UV-resistant packaging materials include polyethylene films, which are specifically formulated to provide excellent UV protection. By storing the coils in such packaging, they are safeguarded against direct sunlight and other sources of UV radiation. It is worth noting that UV protection measures are particularly crucial during long-term storage or transportation, as the coils may be exposed to UV rays for extended periods. By implementing these protective measures, manufacturers and distributors ensure that the aluminum coils maintain their quality and performance, even when stored in environments with high UV exposure.

- Q: What are the different sizes available for aluminum coils?

- The sizes available for aluminum coils can vary depending on the manufacturer and specific requirements. However, common sizes range from narrow coils with widths as small as 0.2 inches to wider coils with widths up to 72 inches. The thickness of these coils can also vary, typically ranging from 0.006 to 0.25 inches.

- Q: How are aluminum coils tested for surface roughness?

- Aluminum coils are tested for surface roughness using various methods to ensure they meet the required quality standards. One commonly used method is the use of a surface roughness tester or profilometer. This instrument measures the roughness of the coil surface by running a stylus or probe across the surface and recording the variations in height. The surface roughness tester provides data such as Ra (average roughness), Rz (average peak-to-valley roughness), and Rt (total height roughness). These parameters help assess the surface quality of the aluminum coil and determine if it meets the desired specifications. Additionally, visual inspection is often conducted to detect any visible defects, scratches, or irregularities on the surface. This inspection can be done manually by trained operators or with the assistance of automated systems that use cameras and image analysis algorithms to detect imperfections. Another method used to evaluate surface roughness is the use of laser scanners. These scanners emit laser beams that reflect off the surface of the aluminum coil and are then measured to determine the surface profile and roughness. Laser scanners provide high-resolution, non-contact measurements, making them highly accurate and efficient for assessing surface roughness. Overall, a combination of surface roughness testers, visual inspection, and laser scanners are commonly employed to test the surface roughness of aluminum coils, ensuring they meet the required quality standards for various applications.

- Q: Are there any special considerations for handling and storing aluminum coil scraps?

- Yes, there are special considerations for handling and storing aluminum coil scraps. It is important to segregate aluminum scraps from other metals to prevent contamination. They should be stored in a dry and well-ventilated area to avoid moisture absorption and potential corrosion. Additionally, proper labeling and organization are crucial to ensure easy identification and retrieval of the scraps when needed.

- Q: How are aluminum coils packaged for transportation?

- Aluminum coils are typically packaged for transportation in a way that ensures their safety and prevents damage. The packaging process involves several steps to ensure that the coils are well-protected during handling, storage, and shipping. Firstly, the aluminum coils are usually wrapped in a protective material such as plastic or paper to safeguard them from dust, moisture, and other external factors. This wrapping helps to maintain the quality and integrity of the coils throughout the transportation process. After wrapping, the coils are then placed onto a pallet or wooden skid. This allows for easy handling with forklifts or other machinery during loading and unloading. The coils are securely strapped to the pallet to prevent any movement or shifting during transportation, minimizing the risk of damage. To provide additional protection, the coils may be placed inside a wooden or metal crate. This crate acts as a further barrier against potential impacts or rough handling that may occur during transit. The crates are carefully designed to fit the size and shape of the aluminum coils, ensuring a snug fit and preventing any unnecessary movement. Furthermore, depending on the specific requirements and distance of transportation, the coils may also be packed inside a shipping container. This offers an additional layer of protection against external elements and provides stability during long-distance transportation. Overall, the packaging process for aluminum coils prioritizes their safety and protection during transportation. The use of protective wrapping, pallets, crates, and shipping containers ensures that the coils arrive at their destination in optimal condition, ready for further processing or usage.

- Q: What are the different coil lengths available for aluminum coils?

- There are several different coil lengths available for aluminum coils, depending on the specific application and requirements. Generally, aluminum coils can be found in lengths ranging from a few feet to several hundred feet. The most common coil lengths for aluminum coils used in various industries, such as HVAC, automotive, and construction, are typically 50 feet, 100 feet, and 250 feet. However, it's important to note that custom coil lengths can also be manufactured based on the specific needs of the customer. These custom lengths can vary depending on factors like coil thickness, width, and intended use. Ultimately, the available coil lengths for aluminum coils are flexible and can be tailored to suit the needs of different industries and applications.

- Q: Can aluminum coils be used in marine applications?

- Yes, aluminum coils can be used in marine applications. Aluminum is a corrosion-resistant metal that provides excellent durability and strength, making it suitable for various marine environments. It is commonly used in boat building, marine equipment, and other marine applications due to its lightweight nature and resistance to saltwater corrosion.

- Q: Is it safe to use aluminum coil for food storage?

- <p>Using aluminum coil for storing food is not recommended. Aluminum can react with acidic or alkaline foods, potentially leaching aluminum into the food. This can be harmful to health, especially over time. Instead, opt for food-safe materials like glass, stainless steel, or BPA-free plastics for food storage to ensure safety and prevent contamination.</p>

Send your message to us

Aluminum Coils for Sale for ACP, Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords