Aluminum Coil - Continuous Casting Aluminium Coil AA1050 0.2mm-3mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Continuous Casting Aluminium Coil is widly used in building materals in the world. This strip can be rolled down to aluminium coil,sheet,circle ect. Compare to other alloy, the alloy AA1050 is much more cheaper. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

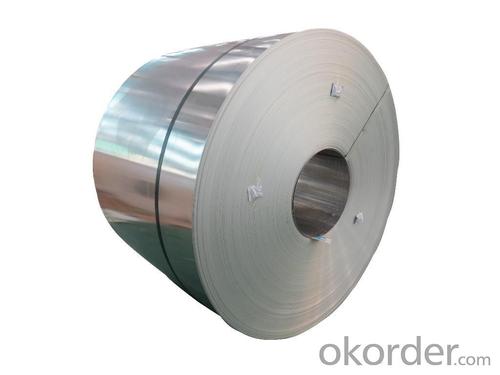

3. Image

4. Products Specifcation

| Alloy | Temper | Thickness | Coil ID | Coil Weight |

| AA1050 | H14 | 0.2mm-3mm | 505mm | 2-2.5 tons |

5. FAQ

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: They say aluminum can be found in deodorants.And this aluminum is absorbed by the skin and block pores.Does the amount of aluminum affect the rate of how it dries up?

- Al does not have the ability to retain heat for very long. Therefore theroretically, the greater the amount of Al the faster the substance would dry.

- Q: What is the composition of aluminum coils?

- Aluminum coils are typically composed of a pure aluminum core, which is surrounded by a protective coating or cladding material on both sides. The cladding material can vary and may include alloys such as aluminum-manganese, aluminum-magnesium, or aluminum-zinc, depending on the specific application and desired properties.

- Q: What are the different elongation values of aluminum coils?

- The elongation values of aluminum coils can vary depending on the specific alloy and temper of the aluminum. However, on average, aluminum coils typically have elongation values ranging from 8% to 30%.

- Q: Can aluminum coils be used in high-pressure or high-temperature environments?

- High-pressure or high-temperature environments typically do not recommend the use of aluminum coils. Although aluminum is known for its high thermal conductivity and resistance to corrosion, it has limitations when exposed to extreme conditions. When it comes to high-pressure environments, aluminum coils may lack the necessary strength and durability required to withstand the forces exerted by pressurized systems. Aluminum has a lower tensile strength compared to metals like steel or titanium, making it more vulnerable to deformation or failure under high pressure. Therefore, it is generally advisable to use materials with higher strength and pressure ratings in such situations. Likewise, aluminum coils have a relatively low melting point compared to metals such as steel or copper. Aluminum's melting point is approximately 660 degrees Celsius (1220 degrees Fahrenheit), which makes it susceptible to damage or failure in high-temperature environments. For applications where the temperature exceeds the melting point of aluminum, it is recommended to use materials with higher temperature resistance. However, it is important to note that there are specialized alloys and coatings available that can enhance the high-temperature and high-pressure capabilities of aluminum. These modifications can improve its strength, heat resistance, and corrosion resistance, making it suitable for certain applications in extreme conditions. Nevertheless, it is crucial to carefully consider the specific requirements and limitations of the intended environment before deciding to use aluminum coils. Seeking advice from experts and considering alternative materials may be necessary to ensure the safety and efficiency of the system.

- Q: How are aluminum coils used in the production of window frames?

- Aluminum coils are commonly used in the production of window frames due to their numerous advantages. These coils are typically made of high-quality aluminum alloy, which provides strength, durability, and resistance against corrosion. To begin the production of window frames, aluminum coils are first unrolled and cut into the desired lengths. These coils are available in various thicknesses, allowing manufacturers to produce window frames of different sizes and specifications. The aluminum coils are then shaped into the required profiles using specialized machines. These profiles can be extruded, bent, or rolled into different shapes, such as rectangular or curved, depending on the design of the window frame. This flexibility in shaping allows for the creation of custom window frames to meet specific architectural requirements. Once the profiles are formed, they are joined together using different techniques like welding or mechanical fasteners. The lightweight nature of aluminum makes it easy to handle during the assembly process, reducing overall production time and costs. Additionally, aluminum coils can be treated with various surface finishes, such as anodizing or powder coating, to enhance their aesthetics and provide further protection against weathering and wear. These finishes also offer a wide range of color options, allowing window frame manufacturers to match the frames with the overall design of the building or the homeowner's preferences. Using aluminum coils in window frame production offers several advantages. Aluminum is a highly sustainable material as it can be recycled repeatedly without losing its properties. It is also lightweight, making the installation process easier and reducing the load on the structure. Moreover, aluminum is a good thermal conductor, which helps in improving energy efficiency by minimizing heat transfer. In conclusion, aluminum coils play a crucial role in the production of window frames. Their strength, durability, flexibility, and aesthetic options make them a preferred choice for manufacturers. Whether it is for residential or commercial applications, aluminum coils provide high-quality window frames that meet industry standards and enhance the overall appearance and performance of buildings.

- Q: What is the typical lead time for manufacturing aluminum coils?

- The lead time for manufacturing aluminum coils can vary depending on several factors, such as the order's specific requirements, the complexity of the manufacturing process, and the manufacturer's current demand and capacity. Typically, the lead times for aluminum coil production range from a few weeks to several months. For standard aluminum coil orders that fall within the manufacturer's regular production capabilities in terms of specifications and quantities, the lead time is usually shorter, around 4-8 weeks. This timeframe includes the sourcing of raw materials, processing, and quality control checks. However, for custom or specialized aluminum coil orders that necessitate specific dimensions, finishes, or additional processing steps like coating or embossing, the lead time can be longer. These types of orders may require additional time for design and engineering, tooling setup, and testing. Consequently, the lead time for these orders can extend to approximately 8-12 weeks or even longer. It is important to consider that lead times can also be affected by external factors like the availability of raw materials, transportation delays, or unforeseen production issues. Therefore, it is advisable to communicate with the manufacturer to obtain an accurate estimate of the lead time for specific aluminum coil orders.

- Q: I'm trying to cast aluminum using plaster and i was wondering if any one know how much the plaster has to be baked and how to tell if the plaster is dried fully and ways to do it. thx

- When okorder /... Aluminum melts at about 1200 F. Silver at about 1700 F. So this would work fine. You would need a Kiln to heat the investment up to these temps - in a pinch a ceramic kiln would work. If you don't get all the moisture out the mold could explode from steam pressure - be careful - read some books or visit some backyard casting sites. Aluminum is also cast using sand casting techniques.Good luck.

- Q: Can aluminum coils be used for structural purposes?

- No, aluminum coils are typically not used for structural purposes as they lack the necessary strength and rigidity required for structural applications.

- Q: Can aluminum coils be recycled multiple times?

- Yes, aluminum coils can be recycled multiple times. Aluminum is a highly recyclable material, and the recycling process does not degrade its quality. This means that aluminum coils can be melted down and reformed into new coils multiple times without any loss in their performance or properties. Recycling aluminum not only helps to conserve natural resources but also saves energy compared to producing new aluminum from raw materials. Therefore, aluminum coils are a sustainable and environmentally friendly choice that can be recycled multiple times.

- Q: Can aluminum coils be used in the manufacturing of furniture?

- Yes, aluminum coils can be used in the manufacturing of furniture. Aluminum is a lightweight and durable material, making it ideal for furniture production. It is commonly used in the construction of outdoor furniture, as it is resistant to rust and corrosion. Aluminum coils can be formed into various shapes and sizes to create different furniture pieces. Additionally, aluminum can be easily customized and finished with different coatings or paint to match any desired aesthetic. Overall, aluminum coils are a versatile and practical choice for furniture manufacturing.

Send your message to us

Aluminum Coil - Continuous Casting Aluminium Coil AA1050 0.2mm-3mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords