Trane Aluminum Coil - Continuous Casting Aluminium Strip in Coils AA1050

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

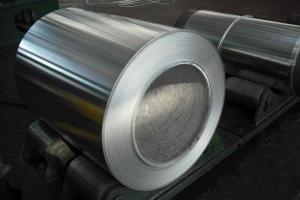

Continuous Casting Aluminium Strip in Coil is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4.Products Specification

| Alloy | Final Usage | Coil ID | Coil Weight | Thickness |

| AA1050 | Aluminium coil/circle | 610mm +/-10mm | Min 5 tons | 3-8mm |

5. FAQ

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Are aluminum coils suitable for architectural façade systems?

- Yes, aluminum coils are suitable for architectural façade systems. Aluminum is a highly versatile and durable material that can be easily shaped and manipulated to meet the specific design requirements of a building's façade. It is lightweight, corrosion-resistant, and can withstand harsh weather conditions, making it an ideal choice for long-lasting exterior applications. Additionally, aluminum coils can be coated with various finishes, such as paint or anodizing, to enhance their aesthetic appeal and provide additional protection against fading or chipping. The flexibility and versatility of aluminum coils make them an excellent option for architectural façade systems, allowing for creative and unique designs while maintaining durability and performance.

- Q: Are there any limitations on the surface treatment of aluminum coils?

- Yes, there are limitations on the surface treatment of aluminum coils. These limitations can vary depending on the specific surface treatment method being used. Factors such as the type of coating or finish being applied, the thickness of the coating, and the compatibility of the treatment with the aluminum alloy can all impose limitations on the surface treatment process. Additionally, environmental and regulatory considerations may also play a role in determining the allowable surface treatments for aluminum coils.

- Q: What’s the standard of tensile strength and ductility of aluminum coil 3003?

- Detailed description can help resolve problems quickly. Performance and status is a related. As aluminum coil is usually semi-hard, the tensile strength is greater than or equals 150, ductility is greater than or equals 12.

- Q: a) Although Aluminium is a reactive metal, it is used to make door frames and window frames.b) Although Aluminium conducts heat, it is used to make blankets, which are good thermal insulators.

- a) Aluminium forms oxide on its surface thus protecting it. This protective oxides help the inner part being corroded / reacted . Its highly maliable and dectile property is also good. Thats why !!!!!!!! b) For making thermal insulators, i think, thin layers (maliability) of aluminium is using, where in between the layers the trapped air which is a poor thermal conductors, which gives the property.

- Q: Is it possible to construct a portable speaker or speaker docking station using aluminum coils?

- <p>Yes, you can use aluminum coils in the construction of a portable speaker or speaker docking station, but they are not the primary component. Aluminum coils can be used in the speaker's electromagnetic parts, such as in the voice coil of the speaker driver or in the transformer of a docking station. However, the main components of a speaker include a diaphragm, voice coil, magnet, and enclosure, while a docking station would require a connector for the device, an amplifier, and possibly additional circuitry. The aluminum coil's role is to facilitate the magnetic field interaction with the voice coil, which converts electrical signals into sound waves. It's essential to consider the entire design and other necessary components when building such devices.</p>

- Q: Can aluminum coils be used in vacuum applications?

- Yes, aluminum coils can be used in vacuum applications. Aluminum is a commonly used material in vacuum systems due to its excellent properties such as low outgassing, high thermal conductivity, and good corrosion resistance. These properties make aluminum coils suitable for various vacuum applications, including but not limited to, vacuum chambers, vacuum pumps, cryogenic systems, and particle accelerators. However, it is important to note that aluminum can be reactive with certain gases or chemicals, so it is essential to consider the specific requirements and compatibility of the vacuum application before using aluminum coils.

- Q: Can aluminum coils be used in the production of cans?

- Yes, aluminum coils can be used in the production of cans. Aluminum is widely used in the manufacturing of cans due to its excellent properties such as lightweight, durability, and corrosion resistance. In the production process, aluminum coils are typically formed into sheets and then cut into the desired size and shape of the can. These sheets are then coated, printed, and formed into cans using various techniques. The use of aluminum coils ensures the production of high-quality cans that are suitable for packaging various beverages and food products.

- Q: wikipedia says welding aluminum by means of stick welding is possible but i have always been told TIG is the only way to weld aluminum. what do i need in order to stick weld aluminum? BTW i have a Lincoln Electric AC 225 Stick Welder

- Aluminum Stick Welding

- Q: Are aluminum coils suitable for heat exchangers?

- Yes, aluminum coils are suitable for heat exchangers. Aluminum has excellent thermal conductivity, corrosion resistance, and lightweight properties, making it an ideal material for heat transfer applications. Aluminum coils can efficiently transfer heat between fluids in heat exchangers, making them a popular choice in various industries.

- Q: Can aluminum coils be painted?

- Yes, aluminum coils can be painted. However, it is important to follow proper surface preparation and use a suitable paint that is compatible with aluminum to ensure a long-lasting and durable finish.

Send your message to us

Trane Aluminum Coil - Continuous Casting Aluminium Strip in Coils AA1050

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords