Aluminum Coil China - Direct from Aluminum Coil Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

aluminium coil

good quality

competitive price

short delivery time

long mutual beneficial business cooperation

Detailed informations

1.Alloy:AA1050,AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5005, AA5052, AA5754, AA5083, AA8011

2.Temper : H12, H14, H16, H18, H22, H24, H26, H32,HO, F

3. Thickness : 0.02mm – 10mm

4. Width : 10mm- 2000mm

5. Standard : ISO9001:2000, SGS , GB/T17748-1999, ASTM, EU standard .

6. Inner diameter : 150mm , 405mm ,500mm 505mm , 508mm

7. Coil weight : 1.5tons – 5.0 tons

8. Surface Quality : be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks,

Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

9. Shipment: By bulk vessel or By container

Applicating:

general using, Roofing, siding panels, shutters, warehouse and pre-fabricated houses, partitions, doors, home appliances, steel furniture,etc.

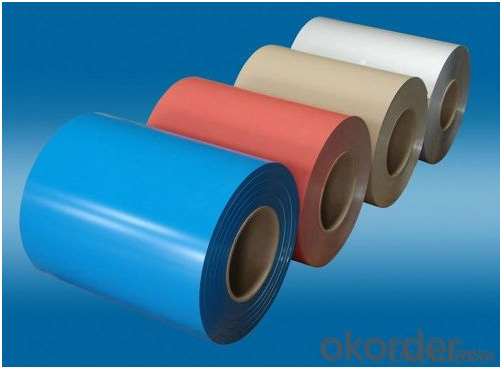

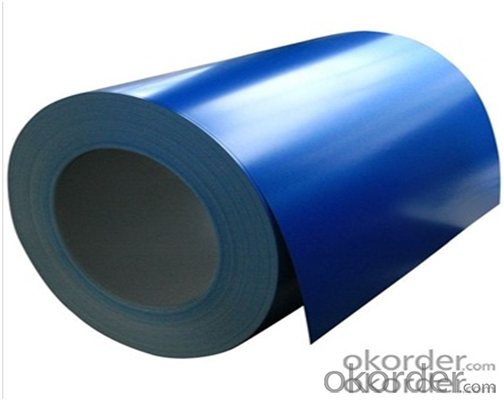

Colored coil is high in strength, good in rain and corrosion resistance,widely used in construction industry, such as modern courtyard design, large-sized industrial buildings, prefabricated thermal insulation sandwich board, etc. Along with the development of light industry, transportation and ship building, the application of colored sheet has been expanded form building materials to automobile manufacturing,watercraft interior decoration. Household electrical appliance, furniture, container and cooker, etc., and become a new material substituting to spray coating steel sheet.

Quality:

is a way of life for us and we live by quality in this industry. The quality of our

products and services are widely recognized and we have been maintaining

international quality standards. All the products that we suppliy pass through stringent

quality test before they finally arrive and that gives us a cutting edge over others,

managing in this sphere.

Product Description

Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are important in other areas of transportation and structural materials. The most useful compounds of aluminium, at least on a weight basis, are the oxides and sulfates.

Despite its prevalence in the environment, no known form of life uses aluminium salts metabolically. In keeping with its pervasiveness, aluminium is well tolerated by plants and animals. Owing to their prevalence, potential beneficial (or otherwise) biological roles of aluminium compounds are of continuing interest.

The earliest citation given in the Oxford English Dictionary for any word used as a name for this element is alumium, which British chemist and inventor Humphry Davy employed in 1808 for the metal he was trying to isolate electrolytically from the mineral alumina. The citation is from the journal Philosophical Transactions of the Royal Society of London: "Had I been so fortunate as to have obtained more certain evidences on this subject, and to have procured the metallic substances I was in search of, I should have proposed for them the names of silicium, alumium, zirconium, and glucium."

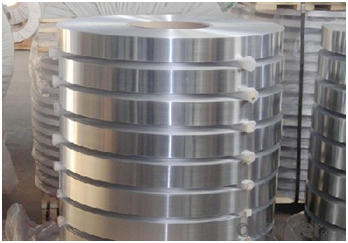

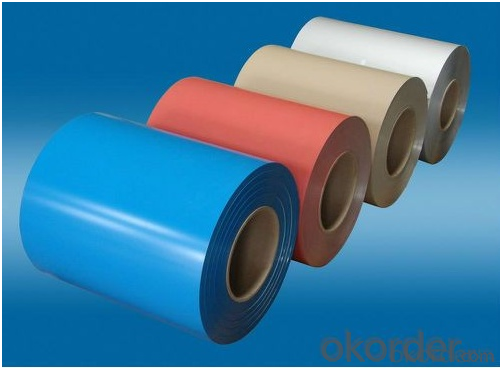

Pictures

FAQ

1. What is the applications?

Outdoor decoration, business chain, exhibition of advertisement decoration and display ,ACP, wall cladding, facades, roofs and canopies, ceilings, signboards, blind window, display platforms, electrical panels etc.

2. What is the popular size?

1000*2000,1200*2400,1219*2438,1220*2440

1000*3000,1250*3000,1500*3000 etc.

3. What is the coating?

Polyester, Fluorocarbon, polyurethane and epoxy coating

4. What is the Surface Quality?

be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks,

Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

5. How about the shipment?

Shipment: By bulk vessel or By container

Welcome to inquiry us! Hope we can establish a long-term relations of cooperation.

- Q: I recently had to have a course of B-12 injections (my digestive system was not properly absorbing other forms). While I felt a significant improvement in mood, energy and memory, I was very concerned to discover that the B-12 shot came with a little something extra: aluminum! I'm wondering if the benefits outweigh the potential risks - why is aluminum placed in the injection? (Are there metal free versions out there?)

- Aluminum salts have been used in vaccines for over 80 years now. They are thought to increase the body's immune response to the vaccines although it is not clear to researchers how this works. However, there is no evidence that it is harmful and the only side effect seems to be increased reddness. The odd thing is that there is usually some sort of metal in any vaccine/shot. If not aluminum salts, there's thimerosal (a mercury-based preservative). The CDC says, btw, that there is no proof that thimerosal causes any harm. However, some studies show a link between thimerosal, aluminum, and a host of other preservatives added to vaccines to autism in children. No news on how it affects adults, but research is being done with respect to Alzheimer's disease. Speak to your doctor to find out he/she has 'metal free' versions of vaccines and about your concerns. Such vaccines are available but are usually very costly to obtain manufacture so doctors usually don't order them as a result.

- Q: This question asks for a comparison between aluminum coil and iron coil, highlighting their distinct properties and uses.

- <p>Aluminum coil and iron coil differ in several aspects. Aluminum coil is lightweight, corrosion-resistant, and has excellent electrical and thermal conductivity, making it ideal for electrical wiring, heat sinks, and food packaging. Iron coil, on the other hand, is heavier, stronger, and more durable, commonly used in construction, automotive, and heavy machinery due to its high tensile strength. Iron also has magnetic properties, useful in applications like transformers and electromagnets. While aluminum is non-magnetic, it is more cost-effective and has better recyclability compared to iron.</p>

- Q: Can aluminum coils be used in the production of aluminum curtain walls?

- Yes, aluminum coils can be used in the production of aluminum curtain walls. Aluminum coils are often used as a raw material for manufacturing curtain walls due to their lightweight, durability, and excellent corrosion resistance. These coils can be easily shaped, cut, and formed into the desired profiles, making them ideal for constructing curtain walls that are commonly used in modern architecture.

- Q: What are the advantages of using aluminum coils over other materials?

- There are numerous benefits to utilizing aluminum coils as opposed to alternative materials. To begin with, aluminum boasts a lightweight composition, thereby facilitating simpler handling and transportation. This characteristic also renders it more cost-effective, as it necessitates less energy for manufacturing and installation. Furthermore, aluminum exhibits a remarkable resistance to corrosion. It remains unaffected by rust, even when subjected to harsh environmental conditions, rendering it highly suitable for outdoor applications. The resulting durability ensures an extended lifespan and diminishes maintenance expenses in the long term. Moreover, aluminum coils excel in terms of heat transfer properties. Possessing a high thermal conductivity, they facilitate efficient heat exchange. This renders them ideal for crucial applications such as heating, ventilation, and air conditioning systems. In addition, aluminum serves as an eminently recyclable material. It can undergo multiple recycling processes without compromising its quality or performance. This not only curtails waste and contributes to environmental sustainability but also lowers production costs. Lastly, aluminum coils offer tremendous versatility in terms of design and customization. They can be effortlessly molded, shaped, and coated to meet specific requirements. This flexibility permits a wide array of applications across diverse industries, including automotive, construction, electronics, and aerospace. In conclusion, the array of advantages associated with aluminum coils, encompassing their lightweight nature, corrosion resistance, heat transfer properties, recyclability, and versatility, establishes them as the favored choice over alternative materials.

- Q: What are the different coil edge profiles available for aluminum coils?

- Aluminum coils come with a variety of coil edge profiles. Some commonly used profiles are: 1. Slit edge: This is the most basic type, where the coil is simply slit to the desired width. The edges of the coil are usually sharp and may have burrs or roughness. 2. Deburred edge: In this profile, the sharp or rough edges of the coil are removed through deburring. Deburring enhances safety and prevents damage to downstream equipment during processing. 3. Rounded edge: This profile involves rounding the edges of the coil through rolling or machining. Rounded edges are often preferred in applications that prioritize safety or involve frequent handling of the coil. 4. Beveled edge: Beveled edge profiles are created by cutting or grinding the edges of the coil at an angle. This profile is commonly used when two coils need to be joined together, as the beveled edges enable a smoother and more secure connection. 5. Custom edge profiles: Depending on the specific requirements of the application, custom edge profiles can be developed. These profiles are tailored to meet the unique needs of the customer and may involve a combination of different edge treatments. It's important to consider the intended application, processing requirements, and desired aesthetic appearance when choosing a coil edge profile. Manufacturers and suppliers of aluminum coils typically offer a range of edge profiles to accommodate different customer needs.

- Q: How are aluminum coils used in the production of window frames?

- Due to its numerous benefits, aluminum coils are widely utilized in the manufacturing of window frames. These coils are typically fabricated from top-notch aluminum alloy, offering qualities such as strength, durability, and resistance to corrosion. To initiate the window frame production process, the aluminum coils are initially unrolled and cut into the desired lengths. These coils come in various thicknesses, enabling manufacturers to produce window frames of different sizes and specifications. Subsequently, specialized machines are employed to shape the aluminum coils into the required profiles. These profiles can be extruded, bent, or rolled into diverse forms, such as rectangular or curved, depending on the window frame design. This flexibility in shaping permits the creation of customized window frames that fulfill specific architectural requirements. Once the profiles are shaped, they are joined together using various techniques such as welding or mechanical fasteners. The lightweight nature of aluminum facilitates easy handling during the assembly process, leading to reduced production time and costs. Furthermore, the aluminum coils can be treated with different surface finishes, such as anodizing or powder coating, to enhance their appearance and provide additional protection against weathering and wear. These finishes also offer a wide array of color options, allowing window frame manufacturers to match the frames with the overall building design or the homeowner's preferences. The utilization of aluminum coils in window frame production brings forth several advantages. Aluminum is an exceedingly sustainable material as it can be recycled multiple times without compromising its properties. Additionally, its lightweight characteristic simplifies the installation process and lessens the burden on the structure. Moreover, aluminum exhibits excellent thermal conductivity, which aids in enhancing energy efficiency by minimizing heat transfer. In conclusion, aluminum coils play a vital role in the production of window frames. Their strength, durability, flexibility, and aesthetic options make them the preferred choice for manufacturers. Whether for residential or commercial applications, aluminum coils provide high-quality window frames that adhere to industry standards and elevate the overall appearance and performance of buildings.

- Q: Are aluminum coils suitable for high-gloss applications?

- Yes, aluminum coils are suitable for high-gloss applications. Aluminum has excellent reflective properties and can be easily polished to achieve a high-gloss finish. Additionally, aluminum is lightweight, durable, and resistant to corrosion, making it an ideal choice for a wide range of high-gloss applications such as automotive trim, signage, and decorative elements.

- Q: Can aluminum coils be used in high-radiation environments?

- Aluminum coils can be used in high-radiation environments, but their performance and durability may be affected depending on the level of radiation exposure. Aluminum is a relatively good conductor of heat and electricity, making it a suitable material for many applications, including coil systems. However, when exposed to high levels of radiation, aluminum can become more susceptible to degradation and corrosion. In high-radiation environments, the primary concern is the potential for radiation-induced damage to the material. Aluminum is considered to have relatively low radiation resistance compared to other metals, such as stainless steel or titanium. As a result, prolonged exposure to high radiation levels can lead to structural changes, including embrittlement and loss of mechanical properties. To mitigate these risks, several factors need to be considered. The specific radiation level, duration of exposure, and the intended application of the aluminum coils are critical in determining their suitability for use in high-radiation environments. Additionally, protective coatings or treatments can be applied to enhance the radiation resistance of the aluminum coils, increasing their durability and longevity. Ultimately, the decision to use aluminum coils in high-radiation environments should be based on a thorough assessment of the radiation levels, the potential risks, and the specific requirements of the application. Consulting with radiation experts and considering alternative materials may be necessary to ensure the best performance and safety in such demanding conditions.

- Q: How do aluminum coils compare to plastic coils in terms of durability?

- Aluminum coils are generally more durable than plastic coils. They are resistant to corrosion and can withstand high temperatures, making them suitable for various applications. Plastic coils, on the other hand, are more prone to wear and tear, especially in harsh environments or with heavy usage. While both types have their own advantages, aluminum coils are generally considered to be more durable in the long run.

- Q: Are aluminum coils suitable for architectural applications?

- Aluminum coils are indeed suitable for architectural purposes. The construction industry often relies on aluminum, a highly adaptable and long-lasting material, for a variety of architectural projects. The use of aluminum coils offers numerous benefits in this field, including their light weight, resistance to corrosion, and ease of shaping into desired forms and sizes. These coils find application in roofing, cladding, facades, gutters, and more architectural areas. Moreover, architects and designers have the option to coat aluminum coils with different finishes, providing a wide array of aesthetic possibilities. In conclusion, choosing aluminum coils for architectural projects is an excellent decision due to their robustness, endurance, and flexibility.

Send your message to us

Aluminum Coil China - Direct from Aluminum Coil Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords