Aluminum Coil Factory Directly Wholesale from China Foshan

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

Thickness: 0.14mm--1.5mm

Width: 600---1250mm

Zinc coating: Zn60---275g/m2 both side

ID coil: 508mm or 610mm

OD coil: Max 1500mm

Surface Treatment: color coated

Coating structure: 2/1 or 2/2

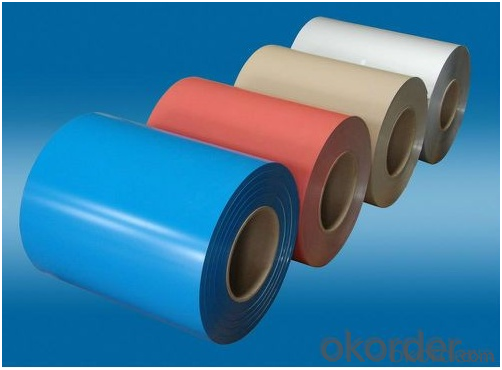

Color: All RAL Colors

Painting thickness: 27-30 microns on top side, 7-9 microns on back Tolerance:+/-0.02mm

Certification: ISO9001

Prepainted Galvanized Coils | Wider Range | Narrow Range | ||

Min. | Max. | Min. | Max. | |

Thickness (mm) | 0.2 | 2.0 | 0.25 | 2.0 |

Width (mm) | 600 | 1250 | 150 | 1000 |

Inside Diameter (mm) | 508 | 610 | 508 | 610 |

Outer Diameter (mm) | 1000 | 2000 | 800 | 1700 |

Prepainted Galvanized Sheets | Wider Range | Narrow Range | ||

Min. | Max. | Min. | Max. | |

Thickness (mm) | - | - | 0.25 | 2.0 |

Width (mm) | - | - | 600 | 1250 |

Length (mm) | - | - | 2000 | 6000 |

Applicating:

general using, Roofing, siding panels, shutters, warehouse and pre-fabricated houses, partitions, doors, home appliances, steel furniture,etc.

Colored coil is high in strength, good in rain and corrosion resistance,widely used in construction industry, such as modern courtyard design, large-sized industrial buildings, prefabricated thermal insulation sandwich board, etc. Along with the development of light industry, transportation and ship building, the application of colored sheet has been expanded form building materials to automobile manufacturing,watercraft interior decoration. Household electrical appliance, furniture, container and cooker, etc., and become a new material substituting to spray coating steel sheet.

Quality:

is a way of life for us and we live by quality in this industry. The quality of our

products and services are widely recognized and we have been maintaining

international quality standards. All the products that we suppliy pass through stringent

quality test before they finally arrive and that gives us a cutting edge over others,

managing in this sphere.

Product Description

Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are important in other areas of transportation and structural materials. The most useful compounds of aluminium, at least on a weight basis, are the oxides and sulfates.

Despite its prevalence in the environment, no known form of life uses aluminium salts metabolically. In keeping with its pervasiveness, aluminium is well tolerated by plants and animals. Owing to their prevalence, potential beneficial (or otherwise) biological roles of aluminium compounds are of continuing interest.

The earliest citation given in the Oxford English Dictionary for any word used as a name for this element is alumium, which British chemist and inventor Humphry Davy employed in 1808 for the metal he was trying to isolate electrolytically from the mineral alumina. The citation is from the journal Philosophical Transactions of the Royal Society of London: "Had I been so fortunate as to have obtained more certain evidences on this subject, and to have procured the metallic substances I was in search of, I should have proposed for them the names of silicium, alumium, zirconium, and glucium."

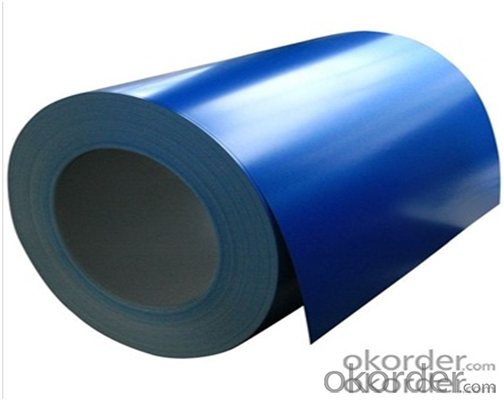

Pictures

FAQ

1. What is the applications?

Outdoor decoration, business chain, exhibition of advertisement decoration and display ,ACP, wall cladding, facades, roofs and canopies, ceilings, signboards, blind window, display platforms, electrical panels etc.

2. What is the popular size?

1000*2000,1200*2400,1219*2438,1220*2440

1000*3000,1250*3000,1500*3000 etc.

3. What is the coating?

Polyester, Fluorocarbon, polyurethane and epoxy coating

4. What is the Surface Quality?

be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks,

Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

5. How about the shipment?

Shipment: By bulk vessel or By container

Welcome to inquiry us! Hope we can establish a long-term relations of cooperation.

- Q: Can aluminum coils be used in solar panel installations?

- Yes, aluminum coils can be used in solar panel installations. Aluminum is a popular material choice due to its lightweight, corrosion resistance, and excellent thermal conductivity. It is commonly used for manufacturing solar panel frames and mounting systems, providing durability and cost-effectiveness in solar installations.

- Q: Are aluminum coils suitable for architectural louvers?

- Indeed, architectural louvers can be constructed using aluminum coils as they possess remarkable corrosion resistance, a lightweight composition, and a commendable strength-to-weight ratio. The malleability and manipulability of aluminum coils grant them the ability to be effortlessly shaped and fabricated into diverse forms and dimensions, thereby rendering them exceptionally suitable for fashioning aesthetically appealing and practical louvers. Moreover, the robustness of aluminum guarantees that the louvers will endure severe weather conditions and retain their structural integrity for an extended period. In conclusion, aluminum coils serve as a dependable and adaptable material choice for architectural louvers.

- Q: This question asks for the distinctions between two types of metal coils: aluminum and iron.

- <p>Aluminum coil and iron coil differ in several aspects. Aluminum coil is lightweight, corrosion-resistant, and has good electrical conductivity, making it ideal for applications like electrical wiring and packaging. Iron coil, on the other hand, is heavier, stronger, and more magnetic, commonly used in construction and manufacturing for reinforcement and structural support. Additionally, iron is more prone to rust compared to aluminum, which is more resistant to corrosion. The cost and availability of these materials also vary, with aluminum being more abundant and less expensive than iron.</p>

- Q: Why 5052 turn black after annealing during the production of aluminum alloy?

- The aluminum oxide in the surface has been oxidized by other chemical elements.

- Q: Is there any way aluminum can affect you if its absorbed into your body either by digestion, through an open cut, or even through breathing it in?Most likely inhaling it would surely affect you, but what about the other two?

- Aluminium can accumulate in the brain possibly causing alzheimers. If you inhaled it it would poison you and damage your lungs, if you got it in your body it would damage your skin, possibly cause an infection and the cut might not heal. Aluminium is a solid so how could you accidently get it in your body unless you have been melting it etc? If it wasn't solid it would burn you if you got it on your skin. You can only inhale vapours not a metal. If you ate it then it would probably damage or clog up your insides otherwise just pass out in a stool, depends how much you ate. People eat from aluminium and touch it every day so it is not dangerous to be in contact with.

- Q: What are the standard dimensions for aluminum coils?

- The standard dimensions for aluminum coils vary depending on the specific application and industry requirements. However, common dimensions for aluminum coils include widths ranging from 36 inches to 72 inches and thicknesses ranging from 0.018 inches to 0.125 inches.

- Q: I have been reading up on thermite and the required ingredients. I have extremely fine aluminum powder from a small etch-a-sketch sitting on plastic wrap in my room. On the comments page of the site i got the thermite ingredients from, multiple people said that thermite could explose if you use too fine of a powder. I have also read that powdered aluminum can become very explosive when it is exposed to air or if it becomes damp. Ive gotten particulary worried because the humidity right now is 93%. So, is powdered aluminum too dangerous to have in house and is too fine powdered aluminum explosive when in thermite?

- It is now not aluminum powder; it's ALUM powder, which is one more chemical. Nonetheless, it would not fairly tighten your vagina, despite what some commercials will say. I've not heard of beydary capsules, but I also doubt that they might do anything to fix the predicament either. If a real vaginal shrinking capsule was once on hand, it would be recognized and really trendy, similar to viagra is. Your best wager is to do kegel exercises to fortify and tone your vaginal muscular tissues. These, and nothing else, can help make your vagina tighter.

- Q: What are the different hardness levels of aluminum coils?

- The hardness levels of aluminum coils are typically categorized into a range from soft to hard, with soft being the lowest hardness level and hard being the highest.

- Q: How are aluminum coils cut to length?

- Aluminum coils are typically cut to length using a process known as shearing or slitting. Shearing involves using a set of sharp blades to cut the coil into multiple shorter lengths. This method is commonly used for thicker aluminum coils. Slitting, on the other hand, is a process in which the coil is passed through a set of rotating circular knives that cut the coil into narrower strips of the desired width. This method is often used for thinner aluminum coils. Both shearing and slitting processes can be manual or automated, depending on the scale of production and the specific requirements of the project. Automated cutting machines are commonly used for large-scale production as they offer higher precision and faster cutting speeds. It is important to note that during the cutting process, the coil is often uncoiled and fed through the cutting machine. Once the desired length or width is achieved, the cut aluminum pieces are then collected, bundled, and prepared for further processing or distribution.

- Q: Are aluminum coils resistant to vibration?

- Aluminum coils, typically, exhibit resistance to vibrations. Being lightweight and flexible, aluminum possesses the capability to absorb vibrations and alleviate their effects. Moreover, aluminum coils find extensive usage in crucial areas where vibration resistance holds significance, such as HVAC systems, automotive components, and electrical transformers. The commendable strength-to-weight ratio of aluminum further contributes to its capacity to endure vibrations without distortion or fracturing. Nevertheless, the precise degree of vibration resistance could vary depending on the distinctive design and construction of the aluminum coil.

Send your message to us

Aluminum Coil Factory Directly Wholesale from China Foshan

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords