Aluminum Coil Anodizers Corp - Alu Coil for Casting for Manufacture to Produce Thinner Rolls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Alu Coil for Casting for Manufacture to Produce thinner Rolls

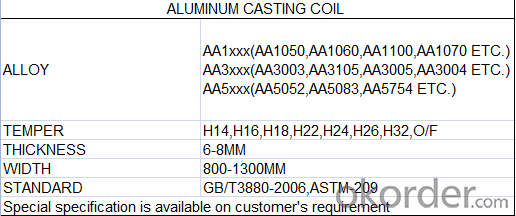

1.Structure of Alu Coil for Casting for Manufacture to Produce thinner Rolls

Alu Coil for Casting for Manufacture to Produce thinner Roll is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. The thickness of Alu Coil for Casting for Manufacture to Produce thinner Roll is about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the Alu Coil for Casting for Manufacture to Produce thinner Rolls

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

3. Alu Coil for Casting for Manufacture to Produce thinner Rolls

4. Production Process of Alu Coil for Casting for Manufacture to Produce thinner Rolls

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of Alu Coil for Casting for Manufacture to Produce thinner Rolls

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q: What’s the standard of tensile strength and ductility of aluminum coil 3003?

- Detailed description can help resolve problems quickly. Performance and status is a related. As aluminum coil is usually semi-hard, the tensile strength is greater than or equals 150, ductility is greater than or equals 12.

- Q: I know aluminum has gone up in price. I know very little about gutter material. Durability, leaf guards, etc. I am on a limited income, and need the most and best for my few bucks. Thanks Lee

- If you want seamless gutters (which are the best way to go) then you want aluminum. Your gutter installer will make them on site and hang them with a quickness. It may not be as expensive as you may think.

- Q: This question asks for methods to check the quality of aluminum coils.

- <p>To inspect aluminum coils for quality, follow these steps: Visually inspect for any surface defects like scratches, dents, or discoloration. Measure the thickness and width to ensure they meet specifications. Check the hardness and tensile strength using appropriate testing equipment. Examine the coil's flatness and straightness to avoid issues in further processing. Assess the surface roughness and cleanliness, as these can affect the coil's performance. Conduct a chemical composition analysis to confirm the alloy type and purity. Perform a magnetic particle inspection or ultrasonic testing to detect any internal defects. Finally, ensure the coil meets the required mechanical properties and specifications as per industry standards.</p>

- Q: What is the typical coefficient of thermal expansion for aluminum coils?

- Aluminum coils usually have a coefficient of thermal expansion around 23 x 10^-6 per degree Celsius. This implies that with each degree Celsius rise in temperature, the length of the aluminum coil will expand by 23 parts per million. The coefficient of thermal expansion holds significance in the design and handling of aluminum coils, as it impacts their dimensional stability and can induce thermal strains in the material due to temperature fluctuations.

- Q: What are the standard dimensions for aluminum coils?

- The dimensions of aluminum coils can vary depending on their intended use and the industry they are being used in. However, there are generally accepted standard dimensions for aluminum coils. In terms of width, aluminum coils can range from 4 inches (10 cm) to 60 inches (152 cm). The exact width will depend on factors such as the purpose of the coils, the manufacturing process, and the customer's specifications. When it comes to thickness, aluminum coils are available in various gauges or millimeters. Common thicknesses can range from 0.018 inches (0.46 mm) to 0.25 inches (6.35 mm) or even thicker in certain applications. The length of aluminum coils can also vary based on customer requirements or industry standards. Coils can be supplied in standard lengths, such as 1000 feet (304.8 meters) or 2000 feet (609.6 meters), or they can be custom-cut to a specific length. It is important to note that these dimensions are not fixed and can be customized to suit the needs of a particular project. Different industries, like construction, automotive, and aerospace, may have their own specific size requirements for aluminum coils. Therefore, it is recommended to consult with an aluminum coil manufacturer or supplier to determine the most appropriate dimensions for a specific application or project.

- Q: How to remove the fingerprint and glue residue on the color aluminum coil?

- Try to use essential balm. We often use the essential balm to remove glue residue on the stainless steel bowl and basin.

- Q: Can aluminum coils be used in the production of railway tracks?

- No, aluminum coils cannot be used in the production of railway tracks. Railway tracks are typically made of steel for several reasons. Steel is a strong and durable material that can withstand the heavy loads and constant wear and tear of train traffic. It also has good heat resistance and can maintain its structural integrity under high temperatures, which is important for tracks that are exposed to friction and heat generated by moving trains. Aluminum, on the other hand, is a lighter metal with lower strength and poorer heat resistance compared to steel. While aluminum may be used in other components of railway infrastructure, such as electrical wires or certain parts of trains, it is not suitable for the production of railway tracks themselves.

- Q: How does the gauge of aluminum coils affect their performance?

- The gauge of aluminum coils refers to the thickness of the aluminum sheet used to manufacture the coil. The gauge is typically measured in terms of its thickness, with a smaller gauge indicating a thicker sheet. The gauge of aluminum coils has a significant impact on their performance. Firstly, the gauge affects the strength and durability of the aluminum coil. Thicker gauges provide increased strength and resistance to bending or warping, making them suitable for applications that require robust and long-lasting coils. On the other hand, thinner gauges are more flexible but may be prone to damage or deformation, making them suitable for less demanding applications. Secondly, the gauge affects the thermal conductivity of the aluminum coil. Thicker gauges have lower thermal conductivity, meaning they are slower to heat up or cool down. This can be advantageous in certain applications where temperature control is crucial, as it helps to maintain a stable environment. Thinner gauges, on the other hand, have higher thermal conductivity, allowing for faster heat transfer. This can be beneficial in applications that require rapid heating or cooling. Thirdly, the gauge affects the weight and cost of the aluminum coil. Thicker gauges are heavier and generally more expensive due to the increased amount of material used. This can be a consideration in applications where weight or cost is a significant factor. Thinner gauges, being lighter and less expensive, can be more suitable for applications where weight reduction or cost efficiency is important. Lastly, the gauge affects the ease of fabrication and formability of the aluminum coil. Thinner gauges are more easily bent, shaped, or formed into desired configurations, making them suitable for applications that require intricate or complex designs. Thicker gauges, while less malleable, can still be formed but may require specialized equipment or processes. In conclusion, the gauge of aluminum coils has a direct impact on their performance. It affects their strength, durability, thermal conductivity, weight, cost, and formability. Therefore, selecting the appropriate gauge for a specific application is essential to ensure optimal performance and efficiency.

- Q: I go on a trip once a year with a group of lets say 10 people, we go for 7 nights and consume on average approx 120 cans of beer each (throughout the week). We have a fire burning the whole time in a hole that we dig approx 1ft deep, then we dispose of each can in the fire and let them melt down never thinking about them again. That's approx 1,200 cans that melt in the one fire hole.Will the aluminum have an affect on the soil? does anyone know what sort of damage this can cause? and for what distance / area around the fire might be affected?The theory amongst the group is that cans do not hurt anything so that's why they take cans instead of glass.Thanks

- Aluminum is very reactive in air and will form a layer of aluminum oxide around the outside of any piece. This oxide layer is very stable which is why aluminum doesn't corrode. Since your block of aluminum will be totally oxidized being in a fire, it's inert and just going to sit in the hole for the foreseeable future. The burning paint might not be healthy to breath but that's about the only hazard. Most common soil is a mixture of aluminum, carbon and silica compounds anyways so you aren't even adding anything particularly exotic. Alternatively, you could bring along a couple fifths of whiskey. It's lighter and has less packaging so it's the environmentally friendly way to get drunk.

- Q: What are the different protective film options for aluminum coils?

- Aluminum coils have a range of protective film options available, each with its own benefits and suitability for different applications. Some commonly used options include: 1. PVC Film: These films are highly resistant to moisture, chemicals, and abrasion, making them a popular choice for protecting aluminum coils. They offer excellent surface protection and come in various thicknesses and adhesive strengths. 2. PE Film: Another popular choice, PE films provide good resistance to moisture and UV radiation. They are generally more cost-effective than PVC films and are available in different grades, such as LDPE and LLDPE. 3. PP Film: Known for their tear resistance and high tensile strength, PP films are ideal for applications where coils may undergo rough handling or transportation. They offer good protection against mechanical damage. 4. PET Film: PET films offer exceptional clarity and transparency, making them perfect for applications that require visual inspection of the coils. They also provide good resistance to heat, chemicals, and abrasion. 5. Adhesive Coatings: In addition to films, adhesive coatings can be used to protect aluminum coils. These coatings are directly applied to the coil's surface and create a protective layer against moisture, corrosion, and scratching. When choosing a protective film for aluminum coils, it is crucial to consider factors such as the intended application, environmental conditions, handling processes, and desired level of protection. Seeking guidance from a supplier or manufacturer can help determine the most suitable option for specific requirements.

Send your message to us

Aluminum Coil Anodizers Corp - Alu Coil for Casting for Manufacture to Produce Thinner Rolls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords