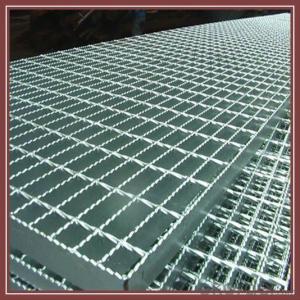

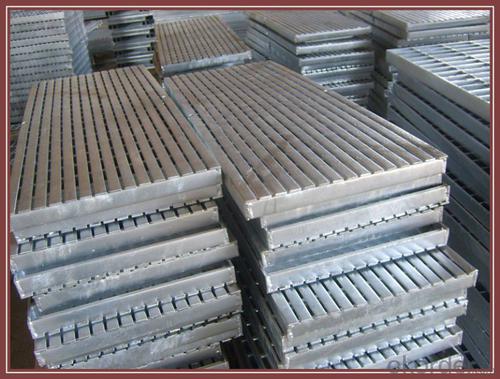

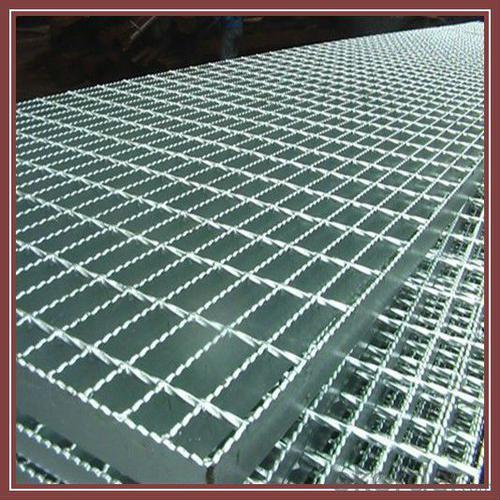

Aluminum Alloy Grating Or Grate Drainage Trench Cover Or Manhole Cover

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Drainage trench cover:

Drainage trench cover is widely used in the urban road, the square, the botanical garden, the wharf, the airport, the parking lot, the road, each kind of industry, the civil project, etc.

2.Main features of Drainage trench cover:

I--Carrying 20 tons of weight

II—Carrying 14 tons of weight

III---carrying 6 tons of weight

IV---carrying 2 tons of weight

V---Carrying pedestrian weight

3.Glass Wool Blanket Images:

4. Drainage Trench Cover Technical Parameters:

These drain cover plate applies to the road cross-sectional and longitudinal drain. The drains width ranging from 200mm to 550mm.

A means the steel grating length

H means the steel grating height

A means the frame length

H means the frame height

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Drainage trench cover is

one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can 101 aluminum sheets be bent or formed into different shapes?

- Yes, 101 aluminum sheets can be bent or formed into different shapes. Aluminum is a highly malleable material, which means it can be easily shaped without breaking or cracking. The specific grade of aluminum, in this case, 101, refers to the alloy composition and may have certain properties that make it more suitable for bending and forming. However, the ability to bend or form aluminum sheets also depends on their thickness, as thicker sheets may require more force and specialized equipment. Overall, with the right tools and techniques, it is possible to bend or form 101 aluminum sheets into a variety of shapes to meet specific requirements.

- Q: Can aluminum sheet be used for reflective surfaces?

- Yes, aluminum sheet can be used for reflective surfaces. Aluminum is known for its high reflectivity, making it a popular choice for various applications that require reflective surfaces. Aluminum sheets can be polished to a high shine, allowing them to reflect light and create a mirrored effect. This makes them ideal for uses such as reflectors in lighting fixtures, solar panels, mirrors, and decorative purposes. Additionally, aluminum's reflective properties make it suitable for applications where heat reflection is required, such as in thermal insulation or roofing materials. Overall, aluminum sheets are a versatile and effective option for creating reflective surfaces.

- Q: Can aluminum sheets be used in outdoor environments?

- Indeed, aluminum sheets are capable of being utilized in outdoor settings. Aluminum, a material that is both highly adaptable and enduring, proves to be a fitting choice for outdoor uses. Its exceptional resistance to corrosion renders it well-equipped to endure environmental factors like rain, snow, and UV radiation. Moreover, aluminum sheets are characterized by their lightweight nature and structural robustness, rendering them appropriate for a multitude of outdoor endeavors, including roofing, siding, and cladding. Furthermore, aluminum's non-combustible nature makes it a secure option for outdoor environments. All in all, aluminum sheets offer a dependable and enduring solution for outdoor applications.

- Q: Can aluminum sheets be used for heat lamps?

- Yes, aluminum sheets can be used for heat lamps. Aluminum has excellent thermal conductivity, which allows it to efficiently transfer and distribute heat. It is commonly used in heat lamps as it can withstand high temperatures and effectively radiate heat.

- Q: Are 101 aluminum sheets suitable for automotive body panels?

- Certainly, automotive body panels can be made suitable by utilizing 101 aluminum sheets. This particular alloy, known as 101 aluminum, possesses remarkable attributes such as high strength, good formability, and corrosion resistance, rendering it an exceptional option for automotive purposes. Moreover, its lightweight composition aids in enhancing fuel efficiency and the overall performance of vehicles. Furthermore, 101 aluminum's impressive dent resistance ensures that body panels can endure impacts while preserving their structural integrity. All in all, opting for 101 aluminum sheets to create automotive body panels proves to be a pragmatic and efficient decision.

- Q: which is the best bonding method for aluminum sheet and plastic?

- smear glue, there is a glue special for the bonding of plastic and steel materials.

- Q: I don't know if the electrons are being passed from my hand to the aluminum or from the aluminum to my hand.Thanks

- Aluminum is a metal and a good conductor of electricity. If you touch it, it will get grounded, so it will be neutral. You cannot charge a metal up by touching it with your hand unless you are not grounded yourself. If you are standing on a piece of plastic, say, then it will take whatever charge is on you. If you are positive, it will become positive. If you are negative, it will become negative. But you must be insulated from ground to do that. If you are touching the ground then any charge on the aluminum will just flow out of the metal through you to ground and the aluminum will stay neutral

- Q: Are aluminum sheets suitable for artistic sculptures?

- Aluminum sheets, indeed, prove to be a suitable choice for artistic sculptures. Boasting versatility, aluminum offers numerous benefits for sculpting endeavors. First and foremost, its lightweight nature makes it easier for artists to handle and manipulate. This quality grants them the ability to fashion intricate and detailed sculptures without compromising on structural integrity. Moreover, aluminum possesses high malleability, allowing it to be molded into diverse forms and contours. This grants artists the freedom to experiment with various designs and achieve their desired artistic expression. Additionally, aluminum's resistance to corrosion and weathering makes it an ideal material for outdoor sculptures. Its durability ensures that the artwork will withstand the elements and maintain its aesthetic appeal over time. Furthermore, aluminum sheets can be effortlessly welded or joined together, enabling artists to create larger and more intricate sculptures. All in all, aluminum sheets furnish artists with a flexible and long-lasting material that nurtures creativity and guarantees longevity in their sculptural masterpieces.

- Q: How does aluminum sheet perform in outdoor applications?

- Aluminum sheet performs exceptionally well in outdoor applications due to its inherent corrosion resistance and durability. It is highly resistant to rust and can withstand exposure to harsh weather conditions, making it ideal for outdoor structures, signage, and cladding. Additionally, aluminum sheets can be coated or painted to enhance their weather resistance and aesthetic appeal. Overall, aluminum sheet is a reliable and long-lasting material for various outdoor applications.

- Q: Can aluminum sheets be waterjet cut?

- Yes, aluminum sheets can be waterjet cut. Waterjet cutting is a versatile method that uses a high-pressure stream of water mixed with an abrasive material to cut through various materials, including metals like aluminum. The waterjet cutting process is effective for aluminum because it does not generate heat, which can potentially deform or damage the metal. It also provides high precision and accuracy, allowing for intricate shapes and designs to be cut with ease. Waterjet cutting is commonly used in industries that require precise and clean cuts in aluminum sheets, such as aerospace, automotive, and manufacturing.

Send your message to us

Aluminum Alloy Grating Or Grate Drainage Trench Cover Or Manhole Cover

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords