Aluminum Sheets AA8079 Epson Print for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

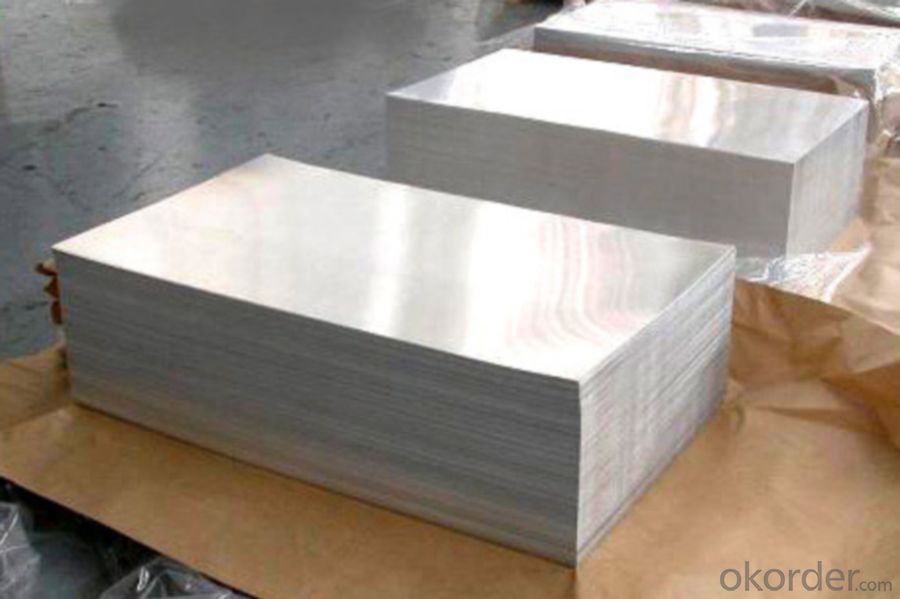

1.Structure of Aluminum Sheets AA8079 Used for Construction Description

Aluminum Sheets AA8079 Used for Construction is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

Aluminum Sheets AA8079 Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of Aluminum Sheets AA8079 Used for Construction

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3.Aluminum Sheets AA8079 Used for Construction Images

4.Aluminum Sheets AA8079 Used for Construction Specification

Alloy | AA8079 |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets AA8079 Used for Construction

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: How do aluminum sheets perform in extreme temperatures?

- Aluminum sheets are known for their excellent performance in extreme temperatures. Aluminum has a high melting point, around 660 degrees Celsius, which makes it capable of withstanding high temperatures without deforming or melting. In extreme heat, aluminum sheets have a low thermal expansion rate, meaning they will not expand or contract significantly, ensuring dimensional stability. This makes them ideal for applications in industries such as aerospace, automotive, and construction, where extreme temperatures are common. Similarly, in extremely cold temperatures, aluminum sheets retain their strength and durability, unlike some other metals that become brittle and prone to cracking. Additionally, aluminum has excellent thermal conductivity, allowing it to distribute heat evenly, which is beneficial in applications where heat dissipation is crucial. Overall, aluminum sheets perform exceptionally well in extreme temperatures, making them a reliable choice for various industries.

- Q: What are the distinctions between standard aluminum windows and those that are custom-made?

- <p>Standard aluminum windows are mass-produced and come in set sizes and styles, offering affordability and quick installation. They may not fit perfectly into unique spaces and may lack customization options. Custom-made aluminum windows, on the other hand, are tailored to specific dimensions and design preferences, ensuring a perfect fit and enhanced aesthetics. They often come with more features and options, such as energy efficiency, security, and unique styling, but are typically more expensive and have a longer lead time for production and installation.</p>

- Q: How do you prevent scratches during transportation of aluminum sheets?

- To prevent scratches during transportation of aluminum sheets, there are several measures that can be taken: 1. Proper packaging: Ensure that the aluminum sheets are packaged securely in appropriate materials such as bubble wrap, foam, or cardboard to provide cushioning and protection from external impacts. 2. Use protective layers: Place protective layers such as paper or plastic film between individual sheets to prevent direct contact and minimize chances of scratching. 3. Secure stacking: When loading aluminum sheets onto transportation vehicles, ensure they are stacked securely to prevent any movement or shifting during transit. This can be achieved by using appropriate strapping or palletizing techniques. 4. Handling with care: Train personnel involved in the transportation process to handle the aluminum sheets with care, avoiding dragging or sliding them against rough surfaces that may cause scratches. 5. Avoid contact with sharp objects: Make sure that the aluminum sheets are not in contact with sharp objects or edges that may cause scratches. This can be achieved by keeping them away from other materials or using protective covers. 6. Regular inspection: Regularly inspect the aluminum sheets during transportation to identify any potential scratches or damages. If any are found, immediate action should be taken to prevent further damage. By following these preventive measures, the chances of scratches occurring during the transportation of aluminum sheets can be significantly reduced, ensuring that the sheets are delivered in optimal condition to their destination.

- Q: Explain the various types of coatings that can be applied to aluminum sheets.

- <p>Aluminum sheets can be coated with several options to enhance their appearance, durability, and functionality. These include: 1) Anodizing, which creates a protective oxide layer, 2) Powder coating, offering a wide range of colors and textures, 3) Liquid painting, for a smooth, painted finish, 4) Laminating, which bonds a protective film to the surface, 5) Electrolytic coloring, resulting in a variety of colors, 6) PVD (Physical Vapor Deposition), for a high-quality, durable finish, and 7) Thermal spraying, applying a coating to improve wear resistance. Each method serves different purposes and has its advantages and limitations.</p>

- Q: What type of aluminium sheet is a food grade?

- Pure aluminum, alloy aluminum can be. However, the majority of pure aluminum. Used by customers. You can inquire about our company: dexincheng Pioneer Metals corporation. Baidu will find the phone soon.

- Q: What kind of aluminum sheet can be bent with five millimeters?

- Aluminum plate can not be called grade, I give the high-speed rail processing bending sound barrier is aluminum, bending effect is very good.

- Q: This question asks for methods to ensure a project remains cost-effective when using aluminum sheets.

- <p>To ensure your project is cost-effective using aluminum sheets, first, source high-quality aluminum at competitive prices. Consider buying in bulk to reduce per-unit costs. Second, optimize your design to minimize material usage without compromising strength. Use precise cutting techniques to reduce waste. Third, collaborate with reliable suppliers who can offer cost-effective solutions and may provide discounts for long-term partnerships. Lastly, monitor and control your project's budget closely, and consider the lifecycle costs, including maintenance and potential resale value, to ensure long-term cost-effectiveness.</p>

- Q: Can the aluminum sheets be used in marine environments?

- Yes, aluminum sheets can be used in marine environments. Aluminum is highly resistant to corrosion and has excellent marine-grade properties, making it a suitable material for various marine applications such as boat hulls, decks, and structures.

- Q: What is the cost of aluminum sheets compared to other materials?

- The cost of aluminum sheets compared to other materials can vary depending on various factors such as the thickness, size, quality, and market conditions. However, in general, aluminum sheets tend to be more affordable than certain materials like stainless steel or copper. Aluminum is widely available and has a lower production cost, which contributes to its relatively lower price point. Additionally, aluminum is lightweight, durable, and resistant to corrosion, making it a popular choice in various industries. It is important to note that prices may fluctuate due to market demand, availability of raw materials, and other economic factors.

- Q: What are the different types of alloys used in aluminum sheets?

- There are several different types of alloys used in aluminum sheets, each offering unique properties and benefits. Some of the most common alloys include: 1. 3003 alloy: This alloy is commonly used in general-purpose applications due to its excellent formability, corrosion resistance, and weldability. It is often used for cooking utensils, signage, and chemical equipment. 2. 5052 alloy: Known for its high strength and good corrosion resistance, the 5052 alloy is commonly used in marine and automotive applications. It is also used for sheet metal fabrication and structural components. 3. 6061 alloy: This alloy is highly versatile and is used in a wide range of applications, including aerospace, automotive, and structural components. It offers excellent strength, machinability, and weldability. 4. 7075 alloy: Primarily used in aerospace and high-strength applications, the 7075 alloy is known for its exceptional strength-to-weight ratio. It is often used in aircraft fittings, gears, and bike frames. 5. 2024 alloy: Another popular alloy in aerospace applications, the 2024 alloy boasts a high strength-to-weight ratio and excellent fatigue resistance. It is commonly used for aircraft structures, bolts, and rivets. 6. 5083 alloy: This alloy is specifically designed for marine applications due to its outstanding corrosion resistance and high strength. It is often used for boat hulls and structural components. These are just a few examples of the various alloys used in aluminum sheets. Each alloy has its own unique combination of properties, allowing it to excel in specific applications.

Send your message to us

Aluminum Sheets AA8079 Epson Print for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords