China Colored Anodized Aluminum Alloy Factory Aluminum Profile 6063

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Alloy Factory Aluminium Profile 6063 Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Alloy Factory Aluminium Profile 6063 :

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

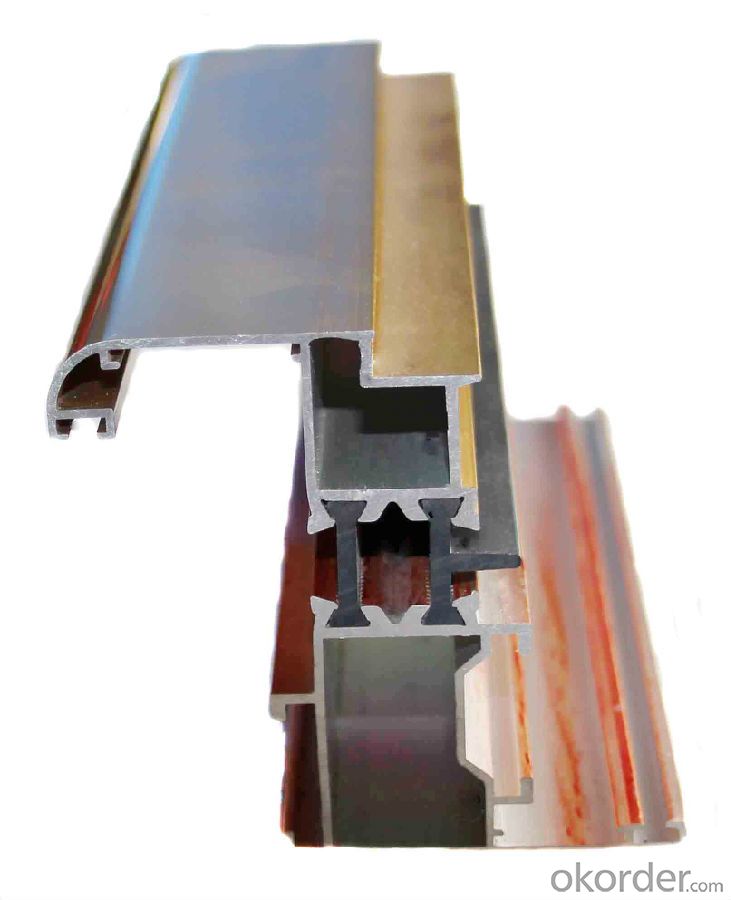

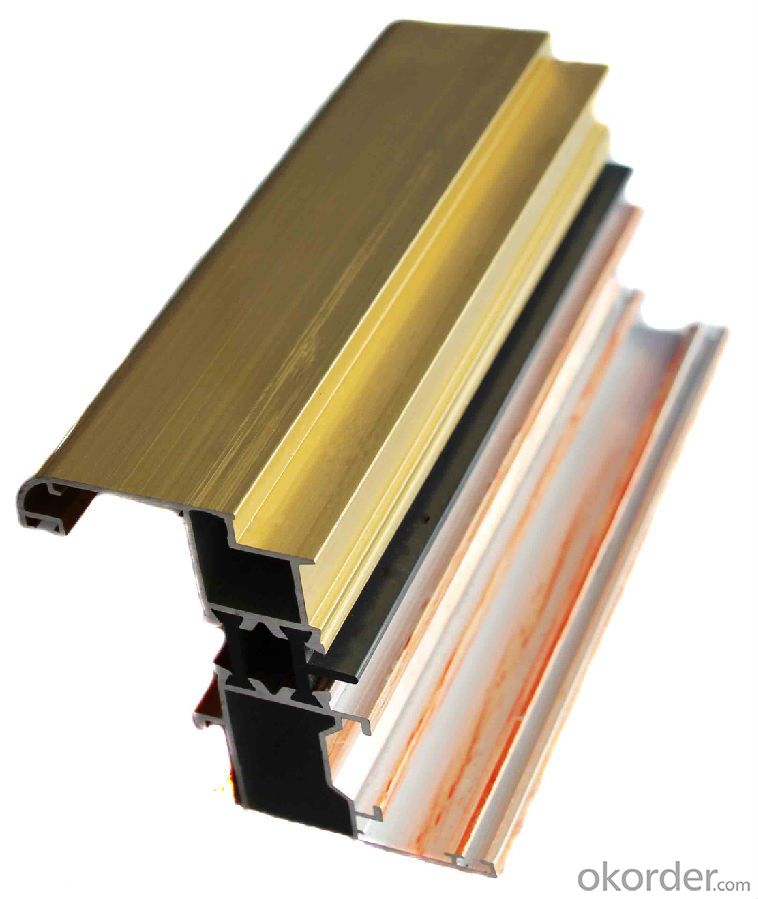

Images of the Aluminium Alloy Factory Aluminium Profile 6063:

Aluminium Alloy Factory Aluminium Profile 6063 Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: are there any carbonated mineral water that are produced in aluminium cans.

- fee, and make contact with. they are the two carbonated interior the comparable way. that is basically a sensible (no longer in my opinion) advertising ploy. A play on words suggesting that one is larger than the different!

- Q: how many aluminum ions are present?how many chloride ions are present?what is the mass in grams of one molecule of aluminum chloride?help! i have no clue how to do this i need to know how for my quiz!!!

- You have to remember Avogadro's number: 6.02 x 10^23 Read about it in your text book. It is the number of molecules of any atom that make up 1 mole. 1 mole of a molecule is equal to it's atomic weight in grams. So, the atomic weight of aluminum is 26.9. So, 26.9 grams of aluminum contains exactly 6.02 x 10^23 molecules of aluminum (or 1 mole). What's the molecular weight of aluminum chloride? Well, 26.9 + 3(35.5) = 133.4 the 35.5 is the molecular weight of chloride and there are 3 of them. So, 133.4 grams of aluminum chloride would be 6.02 x 10^23 molecules. We only have 37.2 g. 37.2 g/ 133.4 g per mole = 0.279 moles. 0.279 moles x (6.02 x 10^23 molecules/mole) = 1.68 x 10^23 molecules of aluminum chloride. So, since there is one aluminum per molecule, you have your answer. Just multiply by three to find out how many molecules of chloride are present. Finally, if 133.4g = 6.02 x 10^23 molecules, then 1 molecule = 133.4 / 6.02x10^23 = 22.16 x 10^-23 or 2.216 x 10^-22 Make sure that the periodic table you use for class has the same values (some tables are more simplified then others). Also, make sure that you use the correct number of scientific digits when calculating your answer.

- Q: Are aluminum sheets resistant to rust?

- Yes, aluminum sheets are highly resistant to rust due to their natural oxide coating that forms a protective barrier against corrosion.

- Q: How do aluminum sheets perform in terms of thermal insulation?

- Aluminum sheets have poor thermal insulation properties. They conduct heat very well, which means they are not effective in preventing heat transfer between different areas or maintaining a consistent temperature.

- Q: Can aluminum sheet be used for electrical enclosures?

- Indeed, electrical enclosures can indeed utilize aluminum sheet. The remarkable conductivity, lightweight composition, and resistance to corrosion render aluminum a favored option for electrical enclosures. It effectively safeguards against electromagnetic interference and possesses commendable heat dissipation properties. Moreover, aluminum boasts malleability, enabling the production of intricate shapes and designs. In summary, aluminum sheet is a fitting material for electrical enclosures and finds widespread application in diverse industries like electronics, telecommunications, and power distribution.

- Q: The user is asking if aluminum sheets can be used as a substitute for metal siding in construction.

- <p>Yes, aluminum sheets can be used to replace metal siding. They are lightweight, durable, and resistant to corrosion, making them a popular choice for siding. Aluminum sheets can be painted or finished to match various architectural styles and are low maintenance. However, it's important to ensure that the aluminum sheets are of the appropriate gauge and quality for the application, and that they are installed correctly to ensure longevity and performance.</p>

- Q: This question asks for a list of various fasteners that are commonly used in the installation process of aluminum sheets.

- <p>There are several types of fasteners used for installing aluminum sheets, including: 1. Self-tapping screws, which create their own threads in the material. 2. Rivets, which join two pieces of material by compressing them together. 3. Pop rivets, a type of rivet that can be installed using a handheld tool. 4. Structural adhesives, which bond the sheets together without visible fasteners. 5. Welding, although not a fastener, it's a method used to join aluminum sheets permanently. 6. Mechanical fasteners like bolts and nuts, which are tightened to secure the sheets. 7. Clips and clamps, used for temporary or decorative installations. Each type has its own advantages and is chosen based on the specific requirements of the installation, such as load-bearing needs, aesthetic considerations, and the environment in which the aluminum sheets will be used.</p>

- Q: This question asks about the ability of aluminum sheets to withstand weather conditions without deteriorating.

- <p>Aluminum sheets have excellent weathering resistance. They are highly resistant to corrosion and oxidation, which makes them suitable for outdoor applications. Aluminum forms a protective oxide layer when exposed to air, which prevents further corrosion. This property allows aluminum sheets to maintain their appearance and structural integrity over time, even in harsh weather conditions. Additionally, aluminum can be coated or anodized to further enhance its resistance to weathering.</p>

- Q: Can aluminum sheets be powder coated?

- Yes, aluminum sheets can be powder coated. Powder coating is a popular finishing process that involves applying a dry powder to a surface, such as aluminum, and then curing it through heat to create a durable and attractive finish. Aluminum is commonly powder coated due to its lightweight, corrosion-resistant, and versatile nature. The powder coating process provides excellent adhesion to aluminum sheets, resulting in a smooth, even, and long-lasting finish. It also offers a wide range of color options and can be used for various applications, including architectural, automotive, and industrial uses.

- Q: How do aluminum sheets compare to copper sheets in terms of conductivity?

- When it comes to conductivity, aluminum sheets and copper sheets have their differences. Copper is known for its exceptional ability to conduct electricity and is considered one of the most conductive metals available. Its high electrical conductivity allows electricity to flow through it with minimal resistance. On the other hand, aluminum, while still a good conductor of electricity, is not as conductive as copper. In fact, aluminum has about 61% of the conductivity that copper possesses. As a result, if high conductivity is a top priority, copper sheets would be the preferred option. However, if cost-effectiveness and lightweight properties are more important, aluminum sheets can still offer adequate conductivity for many applications. Ultimately, the decision between aluminum and copper sheets relies on the specific project requirements and the balance between conductivity, cost, and other factors.

Send your message to us

China Colored Anodized Aluminum Alloy Factory Aluminum Profile 6063

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords