Aluminum 3x8 Sheets - Embossed Aluminum Colorful Sheet from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mirror five bars embossed aluminum sheet

Product Description

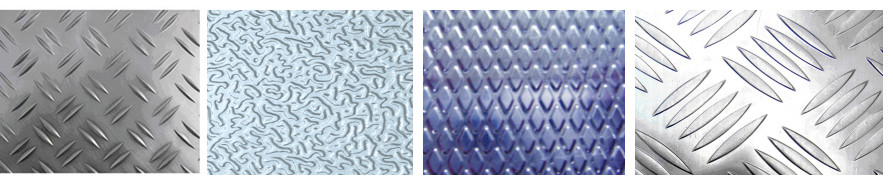

ITEM | ALLOY | PATTERN | THICKNESS | WIDTH | APPLICATION |

ALUMINIUM CHECKERED PLATE | 1000SERIES 3000SERIES 5000SERIES 6000SERIES | DIAMOND 2 BARS 3 BARS 5 BARS | 0.8MM-10MM | 900MM-1600MM | Lighting,construction,printing,packing,decorative, |

Technical Specifications

Thickness: 0.8-10mm

Width: 900-1600mm

Length: 800-8000mm

Material (alloy): 1100, 1050, 3003, 3103, 5052, 5754, 5083, 6061, 6082

Type embossed: diamond(one bar), three bars, five bars,etc

Application

the chequered aluminum sheet Mainly used in Construction , decoration,packaging, printing, cover material,piping, electronic elements, referigeration, air conditioner, automobile, etc

Company Information

CNBM is the key enterprise of aluminum manufacturing, researching and development in CNBM Group, which was founded in 1984.

The aluminum circle, mirror aluminum sheet, plain auminum foil, stucco embossed aluminum foil and aluminum strip are our main products, and our products have been passed the CCC certificate, SGS certificate, BV certificate etc which certificated by the third party, and also CNBM Aluminum has obtained by the ISO9001 certificate, our annual capacity ability is more than 1 billiion.

Packaging & Delivery

| Packaging Details: | 1. Seaworthy export wooden pallet 2. With damp proof film as first layer 3. Kraft paper as second layer 4. Cardboard card as third layer 5. Criss-cross steel strip to fix outside. |

| Delivery Detail: | 10-15 days after receiving the deposit chequered aluminum sheet |

- Q: is general aluminum sheet fire-proof?

- general aluminum sheet is less fireproof than tinfoil.

- Q: What are the different forming techniques for aluminum sheets?

- There are several different forming techniques that can be used to shape aluminum sheets. One common technique is called bending, which involves applying force to the sheet to bend it into a desired shape. This can be done manually using a press brake or through automated processes such as roll forming or stretch forming. Another technique is called deep drawing, which involves using a die and punch to stretch the aluminum sheet into a three-dimensional shape. This process is commonly used to create cylindrical or box-shaped components like cans or containers. Hydroforming is another forming technique that can be used for aluminum sheets. It involves using hydraulic pressure to shape the sheet against a mold or form. This technique is often used to create complex, irregular shapes that would be difficult to achieve with other methods. Spinning is a technique that is commonly used to create symmetrical shapes such as bowls or cones. It involves rotating the aluminum sheet against a mandrel while applying pressure to shape it into the desired form. Finally, there is also a technique called stamping, which involves pressing the aluminum sheet against a die to create a specific shape. This technique is often used for high-volume production of components such as automotive body panels. Overall, these forming techniques offer a range of options for shaping aluminum sheets into various forms and designs, allowing for flexibility and versatility in manufacturing processes.

- Q: Can the aluminum sheets be used for manufacturing musical instruments?

- Yes, aluminum sheets can be used for manufacturing musical instruments. Aluminum is a lightweight and versatile material that can be shaped and tuned to produce various musical sounds.

- Q: Aluminum alloy cable tray is made of a series of aluminum sheets, a series of pure aluminum aluminum plate can do?

- Do you fold it with aluminium plate? It should be about the same. The cold rolled aluminum of the 1 series is still a little bit stronger,I understand the shape of the material, and if the aluminum extrusion molding, direct use of 6063 is the most appropriate.

- Q: Are 101 aluminum sheets easy to work with in terms of cutting, drilling, and shaping?

- Yes, 101 aluminum sheets are generally easy to work with in terms of cutting, drilling, and shaping. Aluminum is known for its lightweight and malleable properties, making it more manageable compared to other metals. The 101 aluminum alloy specifically offers good formability and weldability, making it suitable for various fabrication processes. When it comes to cutting, aluminum sheets can be easily cut using common tools such as a saw, shears, or even a simple utility knife. Similarly, drilling holes in aluminum sheets is relatively easy and can be done with standard drill bits. Lastly, shaping aluminum sheets can be achieved through bending, folding, or using specialized tools like a brake press. However, it's always important to use appropriate safety measures and equipment when working with any metal, including aluminum.

- Q: Some say you should use the 'dull' side of aluminum foil when cooking etc. There's something potentially bad about the shiny side.True or not?

- that is a myth, the only difference might be how much heat is reflected. Go to Discovery or Metacafe and type How it is made, aluminum foil and you will see why it is a myth.

- Q: Are aluminum sheets suitable for signage applications?

- Yes, aluminum sheets are suitable for signage applications. Aluminum is a lightweight and durable material, making it perfect for outdoor signs that need to withstand various weather conditions. It is resistant to rust and corrosion, which ensures the longevity of the sign. Aluminum sheets can be easily customized and cut into different shapes and sizes, allowing for versatile and creative signage options. Additionally, aluminum is a great material for digital printing and can provide high-quality graphics and images. Overall, aluminum sheets offer excellent durability, versatility, and aesthetic appeal, making them a popular choice for signage applications.

- Q: What is the typical torsional strength of aluminum sheets?

- The torsional strength of aluminum sheets can vary depending on factors such as alloy composition, thickness, and manufacturing process. However, aluminum sheets generally have good torsional strength compared to other materials. Commonly used aluminum alloys in sheet form, like 6061-T6 and 5052-H32, have torsional strengths ranging from approximately 22,000 to 40,000 psi. These values indicate the maximum torque the aluminum sheet can withstand before permanent deformation or fracturing. Torsional strength is just one aspect of aluminum sheet's overall mechanical properties. Tensile strength, yield strength, and elongation are other important factors in determining the suitability of aluminum sheets for specific applications. When choosing aluminum sheets for a torsional application, it is crucial to consider specific requirements and consult with material suppliers or engineers to ensure the selected aluminum sheet meets the desired torsional strength criteria.

- Q: Can aluminum sheets be painted after installation?

- Yes, aluminum sheets can be painted after installation. Aluminum is a highly versatile and durable material that can be painted to enhance its appearance or match the surrounding environment. However, it is important to properly prepare the surface before painting to ensure adhesion and longevity of the paint. This typically involves cleaning the surface, removing any dirt or debris, and applying a suitable primer to promote better paint adhesion. Once the surface is prepared, any type of paint can be applied to the aluminum sheet, such as acrylic, oil-based, or epoxy paint. It is recommended to consult with a professional painter or follow the manufacturer's instructions for the specific paint product to achieve the best results.

Send your message to us

Aluminum 3x8 Sheets - Embossed Aluminum Colorful Sheet from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords