42 Inch By 8ft Aluminum Sheets - Embossed Coated Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Specification

ALLOY: AA1*** (AA1050,AA1060,AA1070,AA1100 etc.)

AA3*** (AA3003,AA3004,AA3005,AA3105 etc.)

AA5*** (AA5052,AA5083,AA5754 etc)

AA8*** (AA8011,AA8006 etc)

TEMPER: H14,H16,H18,H22,H24,H26,H32,O/F

THICKNESS: 0.2mm-100mm

WIDTH: 30mm-1700mm

STANDARD: GB/T 3880-2006

Special specification is available on customer's requirement

2.Description

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, nonmagnetic, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface.

Aluminium metal is so chemically reactive that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.The chief ore of aluminium is bauxite.

3.Our advantage

Best quality and price!

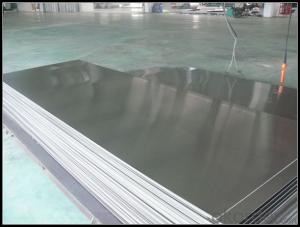

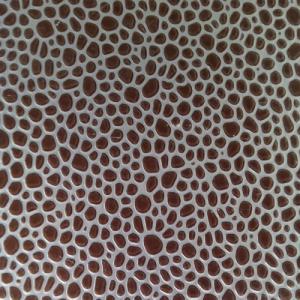

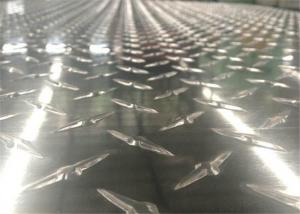

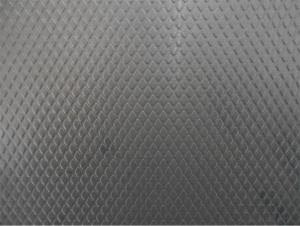

4.Pictures

5.FAQ

1)What's kind of payment term we can supply?

CIF,CFR, FOB and other.

2)Can we supply samples?

Yes, we can!

3)What can you do if you have other quastions?

You can contact us freely at any time!

4)How about our payment term?

LC and TT and other.

5)Which country can we supply?

All around the world!

- Q: What is made when Aluminium and Hydrochloric Acid reacts? It makes a dense white smoke with a metallic odour in the gas. Could it be dissolved amounts of Aluminium Chloride or small amounts of unreacted Aluminium in the gas? Or could be that the Chlorine (in equilibrium with HCl and HClO) made chlorates and perchlorates of aluminium that give off odours?Don't tell me the gas isn't supposed to have an odour. I know what diatomic Hydrogen smells like. Nothing. That's the way it should be. But unfortunately, that's not the way it is.

- i might call the plumber immediately. curiously there's a hollow interior the piping someplace, and the sulfuric acid would desire to have eaten by in spite of advance into clogging that hollow. I doubt that it will supply up leaking via itself, to no longer point out that acid is in all risk leaking into your kitchen in the present day.

- Q: What is the cost of aluminum sheets compared to other metals?

- The cost of aluminum sheets can vary in comparison to other metals, depending on various factors like grade, thickness, size, and market conditions. However, in general, aluminum sheets are typically more cost-effective than other metals. This is because aluminum is one of the most abundant elements on Earth, making it more easily accessible and less costly to produce. Furthermore, aluminum has a lower density than many other metals, meaning that less material is required to achieve the same level of strength and durability. This contributes further to its lower cost. On the other hand, metals such as steel or titanium may be pricier due to their scarcity or higher processing expenses. Nevertheless, it's important to note that prices can fluctuate over time due to various economic factors. Therefore, it is always advisable to check the current market prices before making any purchasing decisions.

- Q: im about to get a grinder online, and i dont know if i should get an aluminum one, or a non aluminum one. cuz i dont know what non aluminum grinders are made out of. thanks

- they can be made outta plastic or wood, prboably something else..but i can't thnk of it. ive had a plastic 1 and it still worked great..even though it was the ch eapest grinder in the store. so..personal preference really. gl

- Q: What are the different edge treatments available for aluminum sheets?

- There are several different edge treatments available for aluminum sheets, each serving a specific purpose or aesthetic preference. Some common edge treatments for aluminum sheets include: 1. Mill Finish: This is the standard edge treatment for aluminum sheets, where the raw edges of the sheet are left untreated after the manufacturing process. It has a smooth, unfinished appearance. 2. Trimmed: In this treatment, the rough edges of the aluminum sheet are trimmed and smoothed to create a clean, rounded edge. This is often done using shearing or milling techniques. 3. Deburred: Deburring is a process where the sharp edges of the aluminum sheet are removed, typically by filing or sanding, to eliminate any potential hazards or sharpness. It results in a smoother, safer edge. 4. Rolled: Rolled edges are created by bending the edges of the aluminum sheet inward or outward. This treatment provides additional strength and rigidity to the sheet and can also enhance its appearance. 5. Anodized: Anodizing is a surface treatment that involves immersing the aluminum sheet in an electrolytic solution and applying an electric current. This creates a protective oxide layer on the surface, which can be colored to provide an attractive and durable edge finish. 6. Powder Coated: Powder coating involves applying a dry powder paint onto the aluminum sheet, which is then heated to form a hard, protective finish. This treatment can be used to create a variety of colors and textures for the edge. 7. Brushed: Brushed finishes are achieved by brushing the aluminum sheet with abrasive materials, creating a textured and visually appealing edge. This treatment is often used for decorative purposes. 8. Polished: Polishing involves buffing the aluminum sheet to create a smooth, reflective surface. This treatment is commonly used for architectural and decorative applications to enhance the appearance of the edge. These are just a few examples of the various edge treatments available for aluminum sheets. The choice of treatment depends on factors such as the intended use, desired aesthetics, and functional requirements of the aluminum sheet.

- Q: Are the aluminum sheets suitable for manufacturing electrical enclosures?

- Yes, aluminum sheets are suitable for manufacturing electrical enclosures. Aluminum is a highly versatile and widely used material in the manufacturing industry, including for electrical enclosures. It offers several advantages that make it suitable for this application. Firstly, aluminum is lightweight yet strong, making it ideal for constructing enclosures that need to be durable while also being easily transportable and installable. Its strength-to-weight ratio is higher than many other metals, allowing for the creation of sturdy enclosures without adding unnecessary weight. Secondly, aluminum has excellent corrosion resistance. This is crucial for electrical enclosures as they are often placed in various environments where they may be exposed to moisture, humidity, or other corrosive elements. Aluminum's natural oxide layer provides a protective barrier against corrosion, ensuring the longevity and reliability of the enclosures. Additionally, aluminum is a good conductor of electricity, which is another important characteristic for electrical enclosures. It allows for efficient dissipation of heat generated by electrical components, preventing overheating and potential damage to the enclosed devices. Furthermore, aluminum is easily machinable and can be formed into various shapes and sizes. This flexibility allows manufacturers to customize the enclosures according to specific requirements, ensuring a perfect fit for the intended electrical components. Lastly, aluminum is a cost-effective material compared to other metals like stainless steel or copper. It offers a good balance between affordability and performance, making it an attractive choice for manufacturing electrical enclosures. In conclusion, aluminum sheets are indeed suitable for manufacturing electrical enclosures due to their lightweight, strength, corrosion resistance, electrical conductivity, machinability, and cost-effectiveness.

- Q: Can 101 aluminum sheets be used in aerospace applications?

- Yes, 101 aluminum sheets can be used in aerospace applications. 101 aluminum is a commonly used alloy in the aerospace industry due to its excellent strength-to-weight ratio, high corrosion resistance, and good formability. It is often used for structural components, such as aircraft skins, wings, and fuselage panels. Additionally, 101 aluminum sheets can be easily machined and welded, making them ideal for aerospace applications where precision and durability are crucial.

- Q: I'm gonna drop the dime and get a bass boat. other than weight why is a fiberglass better than aluminum?I'm looking at the difference between the top of the line BassTracker and the bottom of the line Nitro. I only want about a 90 -115 hp and I'm gonna buy a couple years old to save some money.. so what are the pros - cons?

- This Site Might Help You. RE: aluminum boat vs fiberglass? I'm gonna drop the dime and get a bass boat. other than weight why is a fiberglass better than aluminum? I'm looking at the difference between the top of the line BassTracker and the bottom of the line Nitro. I only want about a 90 -115 hp and I'm gonna buy a couple years old to save...

- Q: How do you prevent fingerprints on aluminum sheets?

- There are several strategies you can use to prevent fingerprints on aluminum sheets: 1. Opt for gloves: To avoid leaving fingerprints on aluminum sheets, a simple solution is to wear gloves while handling them. This creates a barrier between your hands and the surface, preventing any marks or smudges. 2. Thoroughly clean the surface: Before touching aluminum sheets, ensure that the surface is clean. Use a suitable cleaning agent or mild detergent to remove any dirt or oils. Dry the sheets completely with a lint-free cloth to minimize the chances of fingerprints sticking to the surface. 3. Apply a protective coating: Prevent fingerprints by applying a protective coating on the aluminum sheets. Clear lacquer or a clear protective film designed for this purpose are viable options. These coatings create a barrier that reduces the visibility of fingerprints and makes them easier to clean off. 4. Handle with care: Minimize direct contact with aluminum sheets to reduce the likelihood of fingerprints. Fingerprints are more likely to occur when pressure is applied or when the surface is repeatedly touched. Whenever possible, use tools or gloves to manipulate the sheets instead. 5. Proper storage: Ensure that aluminum sheets are stored in a clean and dust-free environment, away from potential contaminants. Consider using protective sleeves or covers to shield the sheets from fingerprints and other marks. By implementing these preventive measures, you can significantly decrease the occurrence of fingerprints on aluminum sheets, maintaining their cleanliness and visual appeal.

- Q: Can aluminum sheets be used in aerospace industry?

- Yes, aluminum sheets are commonly used in the aerospace industry. Aluminum has several properties that make it an ideal material for aerospace applications. Firstly, it is lightweight, which is crucial for aircraft and spacecraft as it helps reduce fuel consumption and increase payload capacity. Secondly, aluminum has excellent strength-to-weight ratio, providing the necessary structural integrity for aerospace components. Additionally, aluminum is highly corrosion-resistant, ensuring durability and longevity in harsh environments. It also has good thermal conductivity, making it suitable for heat dissipation in aerospace systems. Furthermore, aluminum is easily formable, allowing for complex shapes and structures to be manufactured. Overall, the versatility, strength, lightness, and corrosion resistance of aluminum make it a preferred material in the aerospace industry for various applications such as aircraft frames, fuselage panels, wings, and engine components.

- Q: What are the different manufacturing methods for aluminum sheets?

- There are several different manufacturing methods for aluminum sheets, each with its own unique characteristics and applications. 1. Rolling: The most common method of manufacturing aluminum sheets is through rolling. In this process, large slabs of aluminum are passed through a series of rollers, which reduce the thickness of the slab and increase its length. This method can produce sheets with consistent thickness and excellent surface finish. 2. Extrusion: Extrusion is another method used to manufacture aluminum sheets. In this process, a heated billet of aluminum is forced through a die, resulting in a continuous length of sheet. Extrusion allows for complex shapes and profiles to be created, making it suitable for applications such as building construction and automotive components. 3. Casting: Casting involves pouring molten aluminum into a mold and allowing it to cool and solidify into a sheet shape. This method is often used for producing thicker sheets or sheets with specific alloy compositions. Casting can offer unique properties and is commonly used in industries such as aerospace and defense. 4. Cladding: Cladding is a process where a thin layer of aluminum is bonded to another material, such as steel or composite materials. This method combines the desirable properties of aluminum, such as corrosion resistance and lightweight, with the strength and durability of the base material. Clad aluminum sheets are commonly used in construction, transportation, and electrical industries. 5. Powder metallurgy: Powder metallurgy involves the formation of aluminum sheets from powdered aluminum particles. The powder is compacted into a desired shape and then sintered at high temperatures to fuse the particles together. This method is used for producing complex shapes and can provide improved mechanical properties. Each manufacturing method for aluminum sheets has its own advantages and disadvantages, depending on the desired properties, application, and cost considerations. Therefore, it is important to carefully select the most appropriate method based on the specific requirements of the project.

Send your message to us

42 Inch By 8ft Aluminum Sheets - Embossed Coated Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords