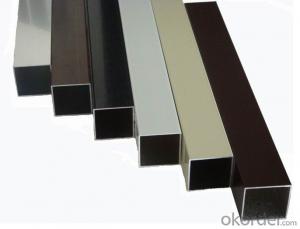

Hafele Aluminum Profiles for Furniture Square Pipes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

aluminium profile tube for construction

1.Square tube aluminium extrusion for door and window

2.aluminum window frame extrusion

3.aluminum extrusion profiles

| material | aluminium |

| color | silver, white, wood |

| sample | free offered |

| usage | door and window |

| MOQ | 5tons |

| surface treatment | powder coated / anodize |

| process | aluminium cutting |

| delivery time | 15-20days |

| shipping port | shanghai / ningbo |

| payment | T/T, Western Union, L/C |

| packing | shrink film |

if you want buy new products,we also can make moulding to produce for you,

we have own factory can produce plastic parts and die casting and metal products.

We are manufacturer for door and window handle, lock,hinge, roller, window operator, plastic parts,gasket, weather seal strip, screw, rivets, glass, pvc door, aluminium profile,door clsoer, crescent lock.

- Q: How do you prevent galvanic corrosion when combining aluminum profiles with concrete or masonry?

- To minimize the occurrence of galvanic corrosion when combining aluminum profiles with concrete or masonry, several precautions can be taken: 1. Opt for suitable materials: Choose aluminum profiles specifically designed for use in conjunction with concrete or masonry. These profiles often come with coatings or treatments that offer protection against corrosion. 2. Insulate the aluminum profiles: Create an insulating barrier between the aluminum profiles and the concrete or masonry surfaces. This can be achieved by utilizing non-conductive materials like gaskets, rubber pads, or coatings. 3. Avoid direct contact: Whenever feasible, try to reduce direct contact between the aluminum profiles and the concrete or masonry. This can be accomplished by utilizing spacers or other methods of separation to establish a gap between the two materials. 4. Ensure proper installation: Follow the manufacturer's guidelines and recommendations to correctly install the aluminum profiles. This includes using appropriate fasteners and techniques to secure the profiles while preserving the insulation and protective measures. 5. Regular upkeep: Conduct regular inspections of the aluminum profiles and the surrounding concrete or masonry to detect any signs of corrosion or damage. Promptly address any issues to prevent further deterioration. By adhering to these preventive measures, the risk of galvanic corrosion between aluminum profiles and concrete or masonry can be significantly reduced, thereby extending the lifespan and performance of the materials involved.

- Q: How do you prevent warping or distortion of aluminum profiles during fabrication?

- To prevent warping or distortion of aluminum profiles during fabrication, there are several key steps that can be taken: 1. Proper storage: Before fabrication, it is crucial to store aluminum profiles in a controlled environment with stable temperature and humidity levels. This helps to minimize any potential changes in the metal's shape or dimensions. 2. Correct handling: Aluminum profiles should be handled with care to avoid bending or twisting. This includes using appropriate lifting equipment, avoiding excessive force, and ensuring that the profiles are supported evenly during transportation. 3. Proper machining techniques: During fabrication, it is important to use appropriate machining techniques that minimize heat buildup. Excessive heat can cause the aluminum to expand and potentially warp. Cooling techniques like using lubricants or coolants can help dissipate heat and prevent distortion. 4. Controlled welding: When welding aluminum profiles, it is crucial to maintain proper control over the welding process. The use of appropriate welding techniques, such as preheating and post-weld heat treatment, can help minimize distortion. 5. Adequate fixturing: Using proper fixturing methods during fabrication helps ensure that the aluminum profiles are held in the correct position throughout the process. This prevents any unintended bending or warping that could occur due to improper support or clamping. 6. Stress-relieving: After fabrication, stress-relieving processes can be employed to minimize residual stresses within the aluminum profiles. This helps to prevent distortion or warping that may occur during subsequent handling or usage. 7. Quality control: Regular inspection and measurement of the aluminum profiles during fabrication can help identify any deviations from the desired specifications. This enables quick corrective actions to be taken, minimizing the risk of warping or distortion. By following these steps, manufacturers can significantly reduce the likelihood of warping or distortion in aluminum profiles during fabrication, ensuring the production of high-quality components or products.

- Q: What are the advantages of industrial aluminum profiles? What are the problems that should be paid attention to?

- Among a large number of aluminum processing materials, a large number of international advanced products and national famous brand products have emerged, representing the mainstream of the development and application of modern aluminum processing technology in china.

- Q: What are the different surface protection coatings for aluminum profiles?

- There are several different surface protection coatings available for aluminum profiles, each offering unique benefits and applications. Some common options include: 1. Anodizing: Anodizing is a widely used coating method that creates a protective layer on the surface of aluminum. It enhances the corrosion resistance, durability, and aesthetics of the profiles. Anodized coatings can be clear or colored, providing options for various design preferences. 2. Powder coating: Powder coating is a popular choice for aluminum profiles due to its durability and versatility. This coating method involves electrostatically applying dry powder to the surface, which is then cured under heat to form a protective layer. Powder coatings offer excellent resistance to UV rays, chemicals, and scratches, while also providing a wide range of color options. 3. Liquid paint coating: Liquid paint coatings are another option for protecting aluminum profiles. This method involves applying a liquid paint to the surface, which is then cured to form a protective film. Liquid paints offer flexibility in terms of color and finish, allowing for customization to meet specific design requirements. 4. E-coating: E-coating, also known as electrocoating or electrodeposition, is a method of applying a paint or coating to aluminum profiles using an electric current. This process creates a uniform and consistent coating, providing excellent corrosion resistance and durability. E-coatings are commonly used in automotive and industrial applications. 5. Ceramic coatings: Ceramic coatings are a newer option for protecting aluminum profiles. These coatings are composed of inorganic materials that provide exceptional hardness, heat resistance, and chemical resistance. Ceramic coatings can enhance the performance and lifespan of aluminum profiles in harsh environments, such as marine or aerospace applications. It is important to consider the specific requirements and intended use of the aluminum profiles when selecting a surface protection coating. Factors such as corrosion resistance, durability, aesthetics, and cost should be taken into account to determine the most suitable coating option.

- Q: This question asks about the various types of aluminum profiles that are utilized specifically for constructing wall frames.

- <p>Aluminum profiles for wall frames come in various types, each serving specific purposes. Common types include: 1) Structural profiles, which provide the main support and strength to the frame; 2) Cover profiles, used to conceal joints and fasteners, enhancing the aesthetic appeal; 3) Insulation profiles, designed to provide thermal insulation; 4) Glazing profiles, used to hold glass or other transparent materials in place; 5) Corner profiles, for joining two walls at a right angle; 6) Sealing profiles, to ensure weatherproofing and airtightness; and 7) Special profiles, tailored for unique architectural designs or specific functions. Each type is chosen based on the structural requirements, design aesthetics, and performance needs of the wall system.</p>

- Q: What are the advantages of utilizing recycled aluminum in construction projects in terms of environmental impact?

- <p>Using recycled aluminum profiles in construction offers significant environmental benefits. It conserves natural resources by reducing the need for mining bauxite, which is the primary source of aluminum. This reduction in mining decreases habitat destruction and soil erosion. Additionally, recycling aluminum requires significantly less energy compared to producing it from raw materials, which cuts down on greenhouse gas emissions and reduces the overall carbon footprint. Furthermore, the use of recycled aluminum helps in waste management by diverting materials from landfills, thereby reducing pollution and the environmental burden of waste disposal.</p>

- Q: This question asks for a list of various fasteners that are used to attach aluminum profiles to building frames.

- <p>There are several types of fasteners used to fix aluminum profiles on building frames, including: 1. Bolts and nuts, which provide a strong and secure connection. 2. Rivets, which are permanent and can't be undone once installed. 3. Screws, which are versatile and can be used in various applications. 4. Clamps, which hold profiles together without penetrating the material. 5. Adhesives, which bond profiles together chemically. 6. Welding, which joins profiles together by melting and fusing them. 7. C-clips and T-nuts, which are specialized fasteners designed for use with aluminum extrusions. The choice of fastener depends on the specific requirements of the project, such as load-bearing capacity, aesthetic considerations, and ease of assembly or disassembly.</p>

- Q: What are the different surface embossing options for aluminum profiles?

- Aluminum profiles offer a variety of surface embossing options, each with its own unique textures and patterns. Some commonly used options include: 1. Diamond pattern: This option creates a diamond-shaped pattern on the profile's surface, providing both visual appeal and improved grip. It is ideal for applications that require slip resistance. 2. Stucco pattern: Stucco embossing creates a textured surface with small, raised bumps. It is often used in applications where aesthetics play a crucial role, such as architectural facades or interior design elements. 3. Hammer tone pattern: This option gives the aluminum profile a hammered texture, providing a distinctive and rustic appearance. It is popular in decorative applications like furniture or light fixtures. 4. Wood grain pattern: Wood grain embossing mimics the texture and look of natural wood. It is commonly chosen for applications like window frames or doors when a traditional or natural appearance is desired. 5. Linen pattern: Linen embossing creates a subtle, fabric-like texture on the profile's surface. It is frequently used in applications that require a sophisticated and elegant finish, such as interior decorative panels or cabinet doors. It's worth noting that these embossing options can be customized or combined to meet specific design requirements. Manufacturers may offer additional options, allowing customers to choose from a wide range of patterns and textures to achieve their desired aesthetic and functional goals.

- Q: What kind of equipment are needed for the production of aluminum profiles?

- Upstairs is a very comprehensive aluminum factory ~!Basic ~!1, casting furnace, do not engage, you can also buy aluminum rod production;2. Extruder;3, aging furnace, used to increase the hardness of aluminum profiles;4. Anodic oxidation line;5, other, double head saw, roll bending machine, forklift, crane and other basic equipment needed for the production.

- Q: Are aluminum profiles suitable for decorative applications?

- <p>Yes, aluminum profiles are commonly used for decorative purposes. They offer a sleek, modern look and are lightweight, durable, and resistant to corrosion. They can be anodized or powder coated in various colors to match different design aesthetics. Aluminum profiles are versatile and can be used in architectural features, furniture, and various other decorative elements.</p>

Send your message to us

Hafele Aluminum Profiles for Furniture Square Pipes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords