Aluminum Sheets for Boat Decking / Deep-Drawing Aluminum Sheets / Coated Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.specification

material: | Alloy or not | ||

thickness: | 1,3 series | 0.3-9.5mm | |

5series | 0.5-150mm | ||

6 series | 5-150mm | ||

7series | More than 6mm | ||

width: | 1,3 series | 900-1500mm | |

5 series | 900-1500mm | ||

6 ,7series | As your request | ||

Circulation size: (width*length)

| 1220*2440mm 1250*2500mm 1500*3000mm 1000*2000mm | ||

Usage : | Boat, plane, building, packaging, machine…. | ||

MOQ | 3 tons | ||

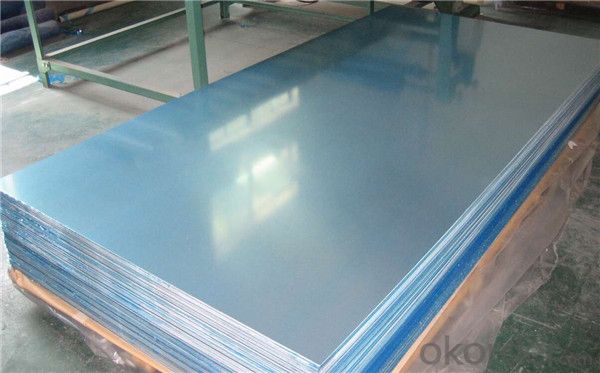

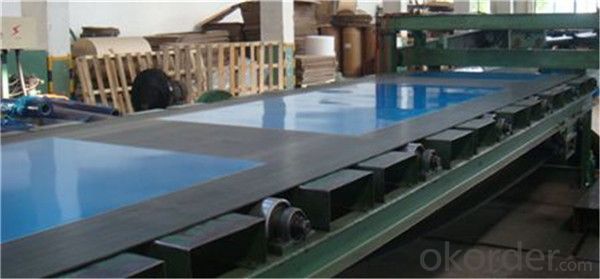

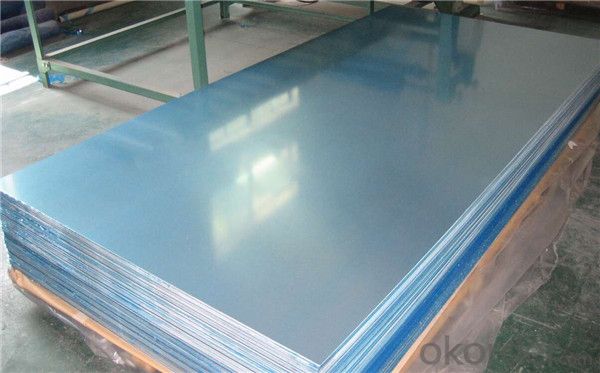

2.product show

Dear Customer, why do I have the confidence to let you buy our product ?

♥strict chemical composition , good hardness high safety performance

♥Oxide film thickness, corrosion resistance

♥Standard aluminum closed time, no rust

♥smooth surface, no burrs

Our VS others

3.shipping:

20~25 working days & send samples:2--3 days after received your advance payment

Mode of transport | advantage | disadvantage | advice |

Express delivery | Fast(3—6days ),door to door wide area coverage | Volume & weight restricted | Good for small cargo |

Sea transpoet | Cheapest volume unlimited | Long sailing time influenced by climate and port conditions | Bulk cargo loose time |

Air transport | Fast(4—5days) simple packaging | The most expensive volume restrict | For valuable cargo urgent need |

Railway | Big volume more expensive | Tracking difficult transit organization may cause delay | Preferred in central Asia |

4.Product photos

- Q: Can aluminum sheets be coated with protective films?

- Yes, aluminum sheets can be coated with protective films.

- Q: Can aluminum sheets be used for architectural cladding?

- Yes, aluminum sheets can be used for architectural cladding. Aluminum is a popular choice for cladding due to its durability, lightweight nature, and resistance to corrosion. It is commonly used in both residential and commercial buildings for its aesthetic appeal and versatility in various architectural designs.

- Q: Is it possible to use aluminum sheets as a material for the exterior walls of a building?

- <p>Yes, aluminum sheets can be used for exterior walls. They are lightweight, durable, and resistant to weathering and corrosion, making them suitable for facades. Aluminum sheets can be easily shaped and offer design flexibility. They also have good thermal properties and can be coated or finished in various ways to enhance their appearance and performance. However, they may not provide the same insulation as traditional materials, so additional insulation may be required.</p>

- Q: Is the process of installing aluminum sheets considered simple or straightforward?

- <p>Aluminum sheets are generally considered easy to install, especially with the right tools and some basic knowledge of construction or home improvement. They are lightweight, which makes handling and positioning them simpler compared to heavier materials. Installation typically involves measuring, cutting the sheets to size, and attaching them to a frame or substrate using screws or adhesives. Proper alignment and securing are crucial for a professional-looking finish. For complex installations or high structures, professional assistance may be necessary to ensure safety and adherence to building codes.</p>

- Q: What are the different types of alloys used for anodized aluminum sheets?

- There are several different types of alloys that can be used for anodized aluminum sheets, each with its own unique properties and applications. Some of the commonly used alloys include: 1. 1000 series alloys: These alloys are primarily made of pure aluminum and are known for their excellent corrosion resistance. They are commonly used for anodized aluminum sheets in various industries, including architecture, automotive, and aerospace. 2. 5000 series alloys: These alloys contain magnesium as the primary alloying element, which provides enhanced strength and excellent weldability. They are often used for anodized aluminum sheets in applications that require high strength and resistance to atmospheric corrosion. 3. 6000 series alloys: This series of alloys is known for its excellent combination of strength, extrudability, and corrosion resistance. The most commonly used alloy in this series for anodized aluminum sheets is 6061, which is widely used in structural components, marine applications, and consumer electronics. 4. 7000 series alloys: These alloys are known for their exceptional strength and are typically used in applications that require high-performance materials. The most common alloy in this series for anodized aluminum sheets is 7075, which is widely used in aerospace and defense industries. 5. 2000 series alloys: These alloys are primarily used in applications that require high strength and excellent fatigue resistance. They are commonly used in the aerospace industry for anodized aluminum sheets. It's important to note that the choice of alloy for anodized aluminum sheets depends on the specific requirements of the application, including desired strength, corrosion resistance, and other mechanical properties.

- Q: This question asks about the various grades of aluminum sheets and the impact of these grades on their pricing.

- <p>Aluminum sheets are categorized into different grades based on their composition and properties. The most common grades include 1000 series (99% pure aluminum), 3000 series (aluminum-manganese alloys), 5000 series (aluminum-magnesium alloys), and 6000 series (aluminum-magnesium-silicate alloys). Each grade has unique characteristics affecting their applications, such as corrosion resistance, strength, and formability. The price of aluminum sheets varies with the grade due to differences in purity, alloying elements, production complexity, and market demand. Purity and the addition of alloying elements can increase the cost, while the availability and demand in the market also influence pricing. For instance, 1000 series sheets are generally cheaper due to their high purity and lack of alloying, while 6000 series sheets, known for their strength and durability, command a higher price.</p>

- Q: Can aluminum sheet be used for automotive body panels?

- Yes, aluminum sheet can indeed be used for automotive body panels. Aluminum is a lightweight and corrosion-resistant material, making it desirable for improving fuel efficiency and increasing vehicle performance. It is widely used in the automotive industry to manufacture body panels, such as hoods, doors, fenders, and roofs, as it offers strength, durability, and design flexibility.

- Q: What are the potential health hazards related to working with aluminum sheets?

- <p>Working with aluminum sheets generally has low health risks. However, inhalation of aluminum dust can cause respiratory issues, such as coughing and shortness of breath. Prolonged exposure may lead to a condition known as metal fume fever. Additionally, aluminum can cause skin irritation in some individuals. It's important to use proper ventilation and personal protective equipment, such as masks and gloves, to minimize these risks.</p>

- Q: I recently moved into a 1975 house with aluminum wiring. I will be going through and checking/replacing all receptacles and switches with CO/ALR rated ones as I don't have a budget right now to rewire the house. I am wondering if I should be checking all of the ceiling lights as well as some of them would be very difficult to access. Are lights as big a concern with aluminum connections as receptacles? I am sure some of the lights are newer and would have copper wire connected to the aluminum. Should I be concerned about the type of wire nuts used here?Anything else that I should be checking?

- There's no problem with aluminum wiring that would require you to rewire your house as long as the proper wire gauge was used. You should replace all of the receptacles and switches with ones rated CO/AL. For lighting, replace the wirenuts with ones rated CO/AL and you'll be fine. From what I remember, Aluminum has a higher resistance than copper so it requires 1 size larger conductors. Aluminum also oxidizes faster than copper. If you have aluminum wires in your panel you should turn the main service disconnect off and put some de-oxidizer (you can find it at home improvement stores in the electrical section) where the wire lug is. This oxidation can make a bad connection causing you to lose voltage as the resistance goes up raising the amperage. This will generate more heat. Aluminum also... well its hard to explain... A/C current cycles its power in a sin wave, it causes the wire to vibrate. You will have to tighten all of the lugs on your electric panel periodically. The CO/AL wirenuts and receptacles/switches help prevent the vibration from loosening the connections causing a short and possibly a shock hazard or even a fire.

- Q: is putting Aluminium foil behind the wind shield actually generate more heat and make the car hotter inside or make the car inside cooler? assume you put foil behind all windows.

- Aluminum foil will absorb heat, just like any other metal (and anything for that matter, but this isn't a discussion about conductors vs. insulators). Whether aluminum foil absorbs heat is the essential issue here. A car gets hot in the sun as a result of the sunlight shining on the car. When the sun shines on a car, the light passes through the windows (because windows are clear) and is absorbs by the interior of the car (e.g. the seat cushions). The absorbed energy is given off as heat, which is trapped in the car (heat doesn't pass through windows like sunlight does). By putting aluminum reflectors in your windshield, you are reflecting away the light and preventing it from reaching the interior of your car. For this reason, putting aluminum shielding in the windows of your car actually keeps your car cooler, and not hotter.

Send your message to us

Aluminum Sheets for Boat Decking / Deep-Drawing Aluminum Sheets / Coated Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords