Led Strip Channels Aluminum Profiles for Windows and Doors Hot Selling Products

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Alloy Profile for Windows And Doors Hot Selling Products

Alloy | AA1050,AA1060, AA1070, AA1100 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-500mm |

Width: | 10mm- 2200mm |

Standard: | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

2. Application of Aluminum Alloy Profile for Windows And Doors Hot Selling Products

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Aluminum Alloy Profile for Windows And Doors Hot Selling Products

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

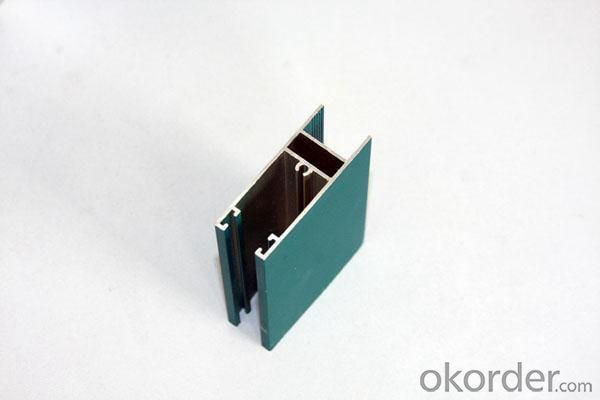

5. Image of Aluminum Alloy Profile for Windows And Doors Hot Selling Products

6. Package and shipping of Aluminum Alloy Profile for Windows And Doors Hot Selling Products

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: How do aluminum profiles perform in terms of heat resistance?

- Aluminum profiles generally exhibit good heat resistance. Aluminum has a high thermal conductivity, allowing it to efficiently dissipate heat. Additionally, aluminum profiles can withstand high temperatures without deforming or losing structural integrity. However, extreme temperatures, especially above 600°C, can cause aluminum to gradually lose strength. Therefore, it is important to consider the specific application and temperature requirements when evaluating the heat resistance of aluminum profiles.

- Q: This question asks for a list of various types of aluminum profiles that are commonly used in the construction industry.

- <p>Aluminum profiles used in construction come in various types, each with specific applications. Common types include: 1. Extruded Profiles: These are the most common, formed by forcing aluminum through a die to create different shapes and sizes. 2. Structural Profiles: Used for structural integrity, such as beams and columns. 3. Decorative Profiles: For aesthetic purposes, like trims and moldings. 4. Industrial Profiles: Designed for specific industrial applications, like conveyor systems. 5. Window and Door Profiles: Specifically designed for window and door frames. 6. Heat Sink Profiles: Used for dissipating heat in electronic devices. 7. Railing Profiles: For constructing railings and balustrades. 8. Solar Profiles: Used in solar panel mounting systems. Each type has unique properties and is chosen based on the specific requirements of the construction project.</p>

- Q: What are the various types of connectors that can be used with aluminum profiles?

- <p>Aluminum profiles can be connected using a variety of connectors designed for different applications and structural needs. Common types include: 1. T-slots connectors, which slide into the T-slots of the profiles for secure attachment. 2. Angle connectors, used to join profiles at right angles. 3. Corner brackets, for creating 90-degree corners. 4. Clamping blocks, which hold profiles together without screws. 5. Hinges, allowing for pivoting movements. 6. End caps, to cover the ends of profiles. 7. Cylindrical connectors, for joining round tubes. 8. Linear connectors, for straight-line connections. 9. Specialized connectors for specific applications, such as cable management or mounting brackets. These connectors are crucial for assembling aluminum profile systems in various configurations.</p>

- Q: How do aluminum profiles compare to plastic profiles?

- Various industries commonly use aluminum profiles and plastic profiles for different purposes. When comparing these two materials, there are several factors that need consideration. Strength and durability are important factors to consider. Generally, aluminum profiles are stronger and more durable than plastic profiles. Aluminum possesses high tensile strength, enabling it to withstand heavy loads and resist deformation. Conversely, plastic profiles are more prone to cracking or breaking under excessive stress. Another factor to consider is weight. Aluminum profiles are heavier compared to plastic profiles. This characteristic can be advantageous or disadvantageous depending on the specific application. The weight of aluminum can provide stability and strength, while the lightweight nature of plastic makes it easier to handle and install. Corrosion resistance is also a significant aspect to examine. Aluminum profiles exhibit excellent corrosion resistance properties, enabling them to endure exposure to various environmental conditions. This makes them suitable for outdoor applications. In contrast, plastic profiles are not as resistant to certain chemicals or UV radiation, which can cause degradation over time. Flexibility and design are important considerations as well. Plastic profiles offer greater design flexibility compared to aluminum profiles. Plastic can be molded easily into complex shapes and customized to meet specific requirements. Aluminum, although less flexible, can still be shaped or extruded into different profiles within certain limitations. Thermal and electrical conductivity should also be taken into account. Aluminum profiles have superior thermal conductivity, allowing them to dissipate heat more effectively. Consequently, they are often used in applications where heat dissipation is critical, such as electronics or heat sinks. Plastic profiles, on the other hand, have lower thermal conductivity and are less suitable for such applications. Cost is another factor to consider. Generally, plastic profiles are more cost-effective than aluminum profiles. The manufacturing process for plastic profiles is simpler and cheaper, resulting in lower production costs. Conversely, aluminum profiles require more advanced manufacturing techniques and additional finishing processes, making them relatively more expensive. In conclusion, the choice between aluminum and plastic profiles depends on the specific requirements of the application. Aluminum profiles offer superior strength, durability, and corrosion resistance, making them suitable for heavy-duty or outdoor applications. On the other hand, plastic profiles provide more design flexibility and cost-effectiveness, making them ideal for lightweight or customized applications.

- Q: How do aluminum profiles perform in terms of energy efficiency?

- Aluminum profiles have excellent energy efficiency performance due to their inherent properties. They are lightweight, durable, and can be easily shaped to optimize thermal insulation. Additionally, aluminum profiles can accommodate double or triple glazing, which further enhances their energy efficiency by minimizing heat transfer and reducing energy consumption for heating or cooling.

- Q: What is the thickness of the aluminum alloy window frame?

- According to the GB / T5237 Aluminum Alloy "building materials" regulations, construction aluminum minimum nominal wall thickness should be not less than 1.2mm, wherein the solid profile wall thickness error of 0.15mm, namely the wall thickness not less than 1.05mm; hollow profile parts containing a closed cavity wall thickness allowance of 0.23mm, the wall thickness is not lower than 0.97mm.

- Q: How do you prevent discoloration or fading of aluminum profiles?

- To prevent discoloration or fading of aluminum profiles, there are several steps that can be taken: 1. Regular cleaning: It is essential to regularly clean aluminum profiles to remove any dirt, dust, or contaminants that can cause discoloration or fading. This can be done using a mild detergent or a specialized aluminum cleaner, followed by rinsing with clean water. 2. Avoid abrasive cleaners: Harsh or abrasive cleaners can cause damage to the surface of aluminum profiles, leading to discoloration or fading. It is important to use gentle cleaning products specifically designed for aluminum. 3. Protective coatings: Applying a protective coating to the surface of aluminum profiles can help prevent discoloration and fading. There are different types of coatings available, such as clear coats or anodizing, that provide a protective barrier against environmental factors. 4. Avoid exposure to harsh elements: Aluminum profiles should be protected from prolonged exposure to harsh elements like direct sunlight, extreme temperatures, or chemicals. These factors can accelerate the discoloration or fading process. If the profiles are installed outdoors, consider providing adequate shading or protective covers to minimize exposure. 5. Regular maintenance: Regular inspection and maintenance of aluminum profiles can help identify any early signs of discoloration or fading. Promptly addressing any issues, such as scratches or surface damage, can prevent further deterioration. 6. Proper storage: If aluminum profiles are not immediately installed, it is important to store them in a dry and well-ventilated area, away from moisture or direct sunlight. Proper storage can help maintain the integrity of the profiles and prevent premature discoloration or fading. By following these preventive measures, it is possible to prolong the lifespan and maintain the aesthetic appeal of aluminum profiles, minimizing the risk of discoloration or fading.

- Q: Can aluminum profiles be used for transportation applications?

- Yes, aluminum profiles can be used for transportation applications. Aluminum is a lightweight and durable material, making it ideal for various transportation purposes. It is commonly used in the construction of vehicles, including cars, trucks, trains, airplanes, and ships. Aluminum profiles can be used to create strong and rigid structures, reducing the overall weight of the vehicle, which in turn improves fuel efficiency and reduces emissions. Additionally, aluminum is resistant to corrosion, making it suitable for outdoor and maritime applications. The versatility and strength of aluminum profiles make them a popular choice in the transportation industry.

- Q: What is aluminum profile?

- Aluminum bars: aluminum bars are obtained by hot extrusion and extrusion so as to obtain aluminum materials of different cross section. The production process of aluminum profile mainly includes three processes: casting, extrusion and coloring. Among them, the color mainly includes: oxidation, electrophoresis coating, fluorine carbon spraying, powder spraying, grain transfer and other processes. Aluminum profile features: 1) corrosion resistance; aluminum profile density is only 2.7g/cm3, about steel, copper or brass density (7.83g/, cm3, 8.93g/, cm3), 1/3. Aluminum can show excellent corrosion resistance in most ambient conditions, including air, water (or brine), petrochemical, and many chemical systems. 2) conductivity; aluminum profile is often chosen because of its excellent electrical conductivity. On the basis of equal weight, the conductivity of aluminum is nearly two times that of copper. 3) thermal conductivity; the thermal conductivity of aluminum alloy is about 50-60% of copper, which is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, as well as the cylinder head and radiator of automobiles.

- Q: What are the anti-static properties of aluminum profiles?

- Aluminum profiles possess excellent anti-static properties due to their inherent electrical conductivity. This conductivity allows them to easily dissipate static charges and prevent the accumulation of static electricity. As a result, aluminum profiles are widely used in applications where static electricity can cause damage or pose a safety hazard. These profiles can be found in industries such as electronics, automotive, aerospace, and manufacturing, where they are used for applications such as conveyor systems, protective enclosures, and grounding components. The anti-static properties of aluminum profiles ensure a safe and reliable operation by minimizing the risks associated with static electricity, including electrostatic discharge (ESD) damage, fire hazards, and interference with sensitive electronic equipment.

Send your message to us

Led Strip Channels Aluminum Profiles for Windows and Doors Hot Selling Products

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords