High Quality Black Aluminum Sheets for Sale - Aluminium Profile T5 with Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Profile T5 Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile T5:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

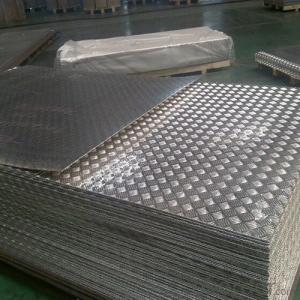

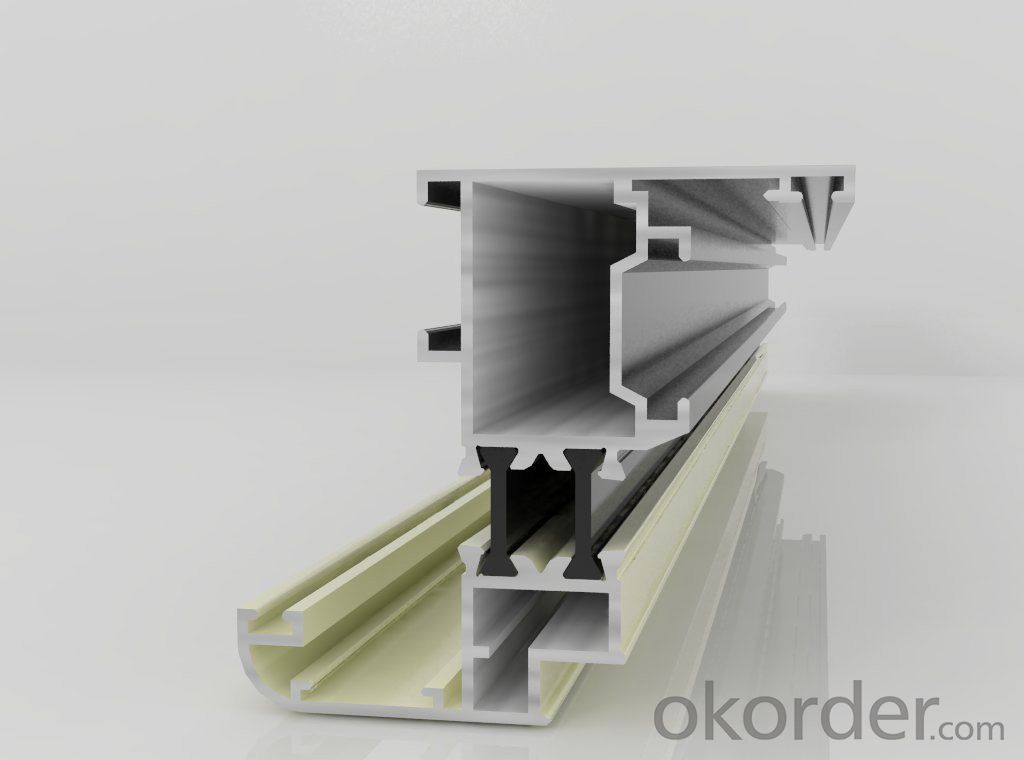

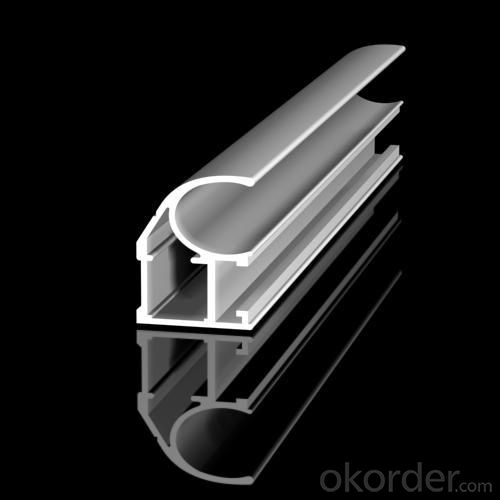

3.Aluminium Profile T5 Images:

4.Aluminium Profile T5 Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

① How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: The which temperature the aluminum evaporates in vacuum?

- Aluminum boils at 2519 °C (4566 °F) at normal pressure. In a vacuum, it might boil (a little) at 808 °C, but actually this is better known as subliming.

- Q: What is the lifespan of an aluminum sheet?

- The lifespan of an aluminum sheet can vary depending on various factors such as the thickness of the sheet, the quality of the aluminum, and the conditions it is exposed to. However, under normal circumstances, aluminum sheets can last for several decades or even longer if properly maintained and protected from corrosion.

- Q: What are the special coatings or treatments available for enhancing the properties of aluminum sheets?

- <p>Yes, there are several special coatings and treatments that can be applied to aluminum sheets to enhance their properties. These include anodizing, which creates a protective oxide layer, powder coating for a durable and colorful finish, and thermal spraying for improved wear resistance. Other treatments involve chemical conversion coatings, such as chromate conversion, which provides corrosion resistance, and various types of plating like electroplating or hot-dip galvanizing for added strength and protection. These treatments can significantly improve the appearance, durability, and performance of aluminum sheets in various applications.</p>

- Q: Can 101 aluminum sheets be used in aerospace applications?

- Indeed, aerospace applications can make use of 101 aluminum sheets. This particular alloy, known as 101 aluminum, is widely employed in the aerospace sector because of its remarkable strength-to-weight ratio, superior resistance to corrosion, and impressive formability. It is frequently utilized in the creation of structural elements, including aircraft skins, wings, and fuselage panels. Furthermore, 101 aluminum sheets can be effortlessly machined and welded, rendering them exceptionally suitable for aerospace applications that demand precision and durability.

- Q: This question asks for methods to ensure that the connections between aluminum sheets are both secure and resistant to water leakage.

- <p>To ensure that the joints between aluminum sheets are secure and watertight, use a combination of sealants and appropriate fasteners. First, clean the surfaces to be joined thoroughly. Apply a high-quality, waterproof sealant along the joint. This sealant should be compatible with aluminum and resistant to UV, temperature changes, and water. Then, use corrosion-resistant fasteners such as stainless steel screws or rivets to join the sheets. Ensure that the fasteners are tightened correctly to prevent leaks. Additionally, consider using a gasket or a weatherstrip along the joint for added watertightness. Regularly inspect and maintain the joints to ensure ongoing watertight integrity.</p>

- Q: This question asks for a comparison between aluminum sheets and other roofing materials, highlighting their differences.

- <p>Aluminum sheets differ from other roofing materials such as asphalt shingles, clay tiles, and metal roofs in several ways. They are lightweight, durable, and resistant to corrosion, making them ideal for coastal areas. Aluminum sheets offer a sleek, modern aesthetic and can be easily recycled, contributing to their environmental friendliness. Unlike asphalt shingles, which have a shorter lifespan, aluminum sheets are long-lasting and can withstand extreme weather conditions. They also don't require the same level of maintenance as clay tiles, which can crack over time. While metal roofs can be similar to aluminum in terms of durability, aluminum sheets are typically more cost-effective and offer a wider range of colors and finishes.</p>

- Q: A copper-aluminum alloy has an aluminum concentration of (5.19x10^2) kg/m3.If the densities of aluminum and copper are 2.71 and 8.94 g/cm3, respectively, what is the concentration of aluminum in wt%?Could someone please help wit this question, im lost

- Densities: Aluminum: 2,710 kg/m^3 Copper: 8,940 kg/m^3 Basis: 1 m^3 of copper-aluminum alloy mass of aluminum in 1 m^3 alloy = 519 kg vol. of aluminum in the 1 m^3 alloy = 519 kg/(2710 kg/m^3) = 0.1915 m^3 vol. of copper in 1 m^3 alloy = 1 m^3 - 0.1915 m^3 = 0.8085 m^3 mass of copper in 1 m^3 alloy = (0.8085 m^3)*(8,940 kg/m^3) = 7,227.87 kg mass of the m^3 alloy = 7,227.87 kg + 519 kg = 7,746.87 kg %weight of aluminum = (519 kg/7,746.87 kg)*100% = 6.70% The alloy has 6.70% by weight of aluminum in it.

- Q: What are the different methods for finishing the edges of aluminum sheets?

- Depending on the desired outcome and application, there are several approaches to finishing the edges of aluminum sheets. One commonly used method is edge trimming, where excess material is removed from the sheet's edges to achieve a smooth and straight edge. This can be accomplished using various tools like shears, saws, or routers. Another technique is edge deburring, which is employed to eliminate any sharp or rough edges left after cutting. Sanding or grinding tools are often utilized to smooth out the edges and produce a more polished finish. Moreover, edge rolling is a method that can be employed to create rolled or rounded edges on aluminum sheets. This is achieved by using a rolling machine that applies pressure to the edges, bending them into the desired shape. For a more decorative finish, edge profiling can be employed. This involves using specialized tools or machines to craft custom edge shapes or designs on the aluminum sheet. It allows for unique and aesthetically pleasing edges that enhance the overall appearance of the sheet. Lastly, edge painting or coating is an option worth considering. This process entails applying a protective or decorative paint or coating to the edges of the aluminum sheet. This not only provides a finished look but also helps protect the edges from corrosion or other damage. Ultimately, the choice of method for finishing the edges of aluminum sheets depends on factors such as the intended use, desired appearance, and specific project requirements.

- Q: What is the density of 101 aluminum sheets?

- The density of 101 aluminum sheets cannot be determined without knowing the dimensions and weight of each individual sheet.

- Q: What is the shear strength of 101 aluminum sheets?

- The shear strength of 101 aluminum sheets can vary depending on various factors such as the thickness of the sheet, the specific alloy composition of the aluminum, and the manufacturing process used. Generally, 101 aluminum sheets have a shear strength ranging from 20,000 to 30,000 pounds per square inch (psi). However, it is important to note that this is a general range and specific values may vary. To obtain the exact shear strength of 101 aluminum sheets, it is recommended to consult the material's technical data sheet or reach out to the manufacturer for more accurate information.

Send your message to us

High Quality Black Aluminum Sheets for Sale - Aluminium Profile T5 with Competitive Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords