Aluminum Sheets in Michigan - Aluminium Profile Industrial for Doors and Windows

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

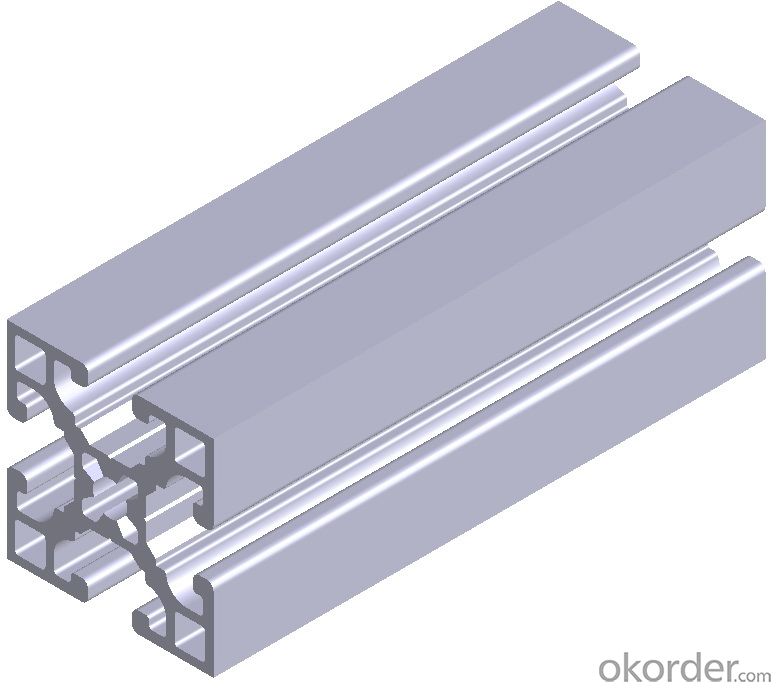

1.Structure of Aluminium profile Industrial for Doors and Windows Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium profile Industrial for Doors and Windows:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

3.Aluminium profile Industrial for Doors and Windows Images:

4.Aluminium profile Industrial for Doors and Windows Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Are aluminum sheets suitable for outdoor uses like fences or signs?

- <p>Yes, aluminum sheets are commonly used for outdoor applications such as fences and signage. Aluminum is lightweight, durable, and resistant to corrosion, making it ideal for outdoor conditions. It can withstand various weather elements without rusting. Additionally, aluminum can be easily formed into different shapes and sizes, and it's available in a wide range of colors and finishes, which makes it versatile for both functional and aesthetic purposes in outdoor settings.</p>

- Q: Are the aluminum sheets suitable for manufacturing automotive fuel tanks?

- Yes, aluminum sheets are suitable for manufacturing automotive fuel tanks. Aluminum is a lightweight and corrosion-resistant material, making it an ideal choice for fuel tank manufacturing.

- Q: Are aluminum sheets suitable for outdoor use?

- Yes, aluminum sheets are suitable for outdoor use. Aluminum is a highly durable and corrosion-resistant material, making it ideal for outdoor applications. It is lightweight, yet strong enough to withstand harsh weather conditions, such as rain, snow, and UV radiation. Additionally, aluminum sheets can be coated or painted to further enhance their resistance to corrosion and provide added protection against the elements. This makes them a popular choice for outdoor structures, signage, roofing, and other exterior applications where durability and longevity are essential.

- Q: Can aluminum sheet be used for medical applications?

- Certain medical applications can utilize aluminum sheet. This material is lightweight, durable, and resistant to corrosion, making it suitable for a range of medical devices and equipment. Prosthetic limbs, braces, and orthopedic implants can be manufactured using aluminum sheets. Additionally, medical instruments like surgical trays, sterilization containers, and imaging equipment can be produced using aluminum. However, it is important to consider that not all medical applications can use aluminum, as some devices may require specific properties or materials to meet regulatory standards and ensure patient safety. Therefore, the use of aluminum sheet in medical applications should be assessed on a case-by-case basis, taking into account the specific requirements and regulations of each application.

- Q: What are the disadvantages of using aluminum sheets?

- Using aluminum sheets comes with several drawbacks. To begin with, aluminum is a relatively soft metal when compared to materials like steel. This softness makes it more susceptible to dents and scratches, which can negatively impact the sheet's overall appearance and structural integrity. Additionally, aluminum is a highly reactive metal, particularly in the presence of certain chemicals or harsh environments. This reactivity leads to corrosion, resulting in the formation of aluminum oxide, a white powdery substance. This corrosion weakens the sheet and compromises its durability. Furthermore, aluminum sheets are not as strong as steel sheets, rendering them less suitable for applications that demand high strength and stiffness. When dealing with heavy loads or extreme conditions, aluminum sheets may not provide the necessary structural support. Another disadvantage of aluminum sheets is their relatively high cost compared to other materials. The production process for aluminum involves energy-intensive steps, making it more expensive to manufacture. This cost can limit their use in projects with budget constraints. Moreover, aluminum sheets exhibit poor thermal and electrical conductivity when compared to metals like copper. This can be a disadvantage in applications where efficient heat transfer or electrical conductivity is required. Lastly, aluminum sheets have a lower melting point than steel, restricting their use in high-temperature applications. Subjecting aluminum sheets to high temperatures can cause them to weaken or deform, compromising their structural integrity. Overall, while aluminum sheets offer advantages such as being lightweight, corrosion-resistant, and versatile, they also come with several disadvantages that must be considered depending on the specific application.

- Q: How do aluminum plates drill?

- Can also be a self tapping screw drill, which can drill.

- Q: Are 101 aluminum sheets suitable for chemical processing environments?

- Chemical processing environments can utilize 101 aluminum sheets effectively. These sheets are made from a commercially pure aluminum alloy known as 101 aluminum, which boasts commendable resistance to corrosion and exceptional weldability. They find extensive application in settings demanding high corrosion resistance, such as chemical processing plants. Moreover, the protective measures of applying a coating or undergoing an anodizing process serve to augment their chemical resistance. In summary, 101 aluminum sheets are an ideal option for chemical processing environments, offering both corrosion resistance and durability when exposed to diverse chemicals.

- Q: Are 101 aluminum sheets suitable for automotive body panels?

- Yes, 101 aluminum sheets are suitable for automotive body panels.

- Q: Are aluminum sheets suitable for architectural louvers?

- Indeed, aluminum sheets prove to be a fitting option for architectural louvers. The advantageous properties of aluminum make it a favored material for louvers in the field of architecture. To begin with, aluminum possesses the desirable combination of being lightweight and yet sturdy, which makes it an ideal material for architectural louvers. It has the ability to withstand external forces such as wind and various weather conditions while maintaining its structural integrity. This becomes crucial for louvers as they are required to provide ventilation and airflow, all the while retaining their form and functionality. Furthermore, aluminum displays a high level of resistance against corrosion and rust. Considering that louvers are frequently exposed to outdoor elements like rain, moisture, and sunlight, the corrosion resistance of aluminum ensures the longevity and durability of the louvers, even in harsh environmental conditions. In addition, aluminum is an adaptable material that can be easily customized and fabricated into different shapes and sizes. This flexibility allows architects and designers to fashion louvers with unique designs and configurations that suit the specific requirements of the building. Aluminum louvers can be personalized to optimize airflow, control light, and enhance aesthetic appeal. Moreover, aluminum stands out as a sustainable and environmentally friendly material. It is widely recyclable, which means that aluminum louvers can be easily repurposed or reused at the end of their life cycle. Opting for aluminum in the construction of architectural louvers aligns with sustainable building practices and contributes to the overall reduction of environmental impact. In conclusion, aluminum sheets are indeed a suitable choice for architectural louvers. Their lightweight yet robust nature, resistance to corrosion, ability to be customized, and sustainability make them an excellent option in terms of functionality, durability, and aesthetics.

- Q: Can 101 aluminum sheets be used in food storage containers?

- Using 101 aluminum sheets in food storage containers is not recommended. These aluminum sheets, often referred to as 101 aluminum, are not suitable for storing food as they are not made from food-grade materials. Typically, they are employed in industrial settings like roofing, construction, and electrical wiring. To guarantee the safety and quality of stored food, it is essential to use containers crafted from food-grade materials such as stainless steel, glass, or food-grade plastic.

Send your message to us

Aluminum Sheets in Michigan - Aluminium Profile Industrial for Doors and Windows

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords