Aluminum Pipes for Building Aluminum Profiles

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

Material | Alloy Aluminum 6063,6061,6005,6082 or customer nominated |

Temper | T3, T4, T5, T6 and other |

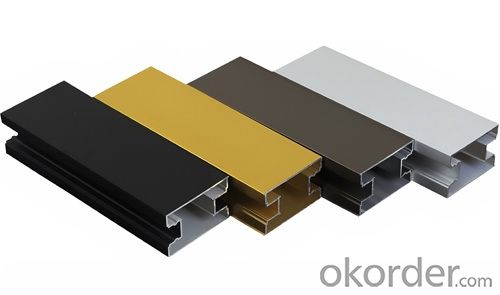

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Not more than 16 meters |

Good Package | Inner plastic film /outside carton/wooden pallets |

Payment Method | T/T, L/C, etc |

Delivery Time | Normally 2-4 weeks, Delivery time can be consulted. |

Press Machine | 500-12500 tons all together 93 press lines. |

Fabrication | 1. Furniture;2. Drilling; 3. Bending; 4. Cutting; 5. Windows and doors;6.etc. |

Certificate | ISO/TS 16949,DNV,IRIS,CCS,AFA,etc. |

Dies | 1. Using our dies, no fee; |

2. Using customer drawing, opening dies, usually about 5~50 tons then the dies cost can be refunded. | |

3. Die cost is negotiable base on the order quantity | |

Capability | Annual output 800,000 tons |

- Q: Can aluminum pipes withstand high wind loads?

- Yes, aluminum pipes can withstand high wind loads. Aluminum is known for its strength-to-weight ratio, making it an ideal material for various applications, including structural elements. Aluminum pipes are commonly used in construction, particularly for outdoor structures such as flagpoles, antennas, and support frames. They have excellent resistance to wind loads due to their high tensile strength and corrosion resistance. Additionally, aluminum pipes can be designed and fabricated to meet specific load requirements, ensuring their ability to withstand high winds.

- Q: Are aluminum pipes suitable for wastewater treatment facilities?

- Yes, aluminum pipes are suitable for wastewater treatment facilities. Aluminum is a durable and corrosion-resistant material, which makes it a suitable choice for numerous applications, including wastewater treatment. It is particularly useful in environments where the pipes are exposed to chemicals or corrosive substances found in wastewater. Aluminum pipes are lightweight, making them easy to install and handle during maintenance or repair work. Additionally, aluminum has a high strength-to-weight ratio, which means it can withstand high pressure and stress without compromising its structural integrity. Overall, aluminum pipes offer several advantages for wastewater treatment facilities, making them a suitable choice for this application.

- Q: Which brands of refrigerator tubes are aluminium tubes and which ones are copper tubes?Ronshen, Meiling, Midea, Hisense, Haier, Hualing and so on, there are some other.

- Hello! At present, the refrigeration pipes in the refrigerator are made up of copper tubes, aluminum tubes and Bondi tubes, which can completely meet the normal use requirements of refrigerators. It's my pleasure to be of service to you and thank you for your support for the enterprise platform!

- Q: How can the refrigerator be welded with copper aluminum tube?

- Welding powder, copper electrode can be used welding!AskExcuse me, is God welding powder? Can you give me more details? Thank you.Chasing the answerI used borax, and now I'm not sure what it is. Now are selling refrigeration parts, where to buy welding powder and welding rod, welding powder 5 pieces, 2 pieces of welding rod!

- Q: How is the seamless pipe or tube seam identification for enlighten heroes?

- Just look at the mold and see the directions

- Q: Can aluminum pipes be used for structural purposes?

- Yes, aluminum pipes can be used for structural purposes. Aluminum is a lightweight and corrosion-resistant material, making it suitable for various structural applications such as building frames, scaffolding, and support structures. Additionally, aluminum pipes offer good strength-to-weight ratio and are easy to work with, making them a popular choice in construction and engineering projects.

- Q: Unique aluminum plastic pipe and folder tubes which do Kaitai warm water pipe is better?

- Italy Ke Yi's pure import aluminum plastic composite pipe is good. In Europe, with imported Swiss good, ground heating pipe is a competitor.

- Q: How many kilograms does the copper pipe withstand? How many kilograms does the aluminum pipe withstand?

- The calculation formula for P=2 * S * t/ (D0.8t)Formula P - hydrostatic pressure of test water, MPaT - pipe wall thickness, mmD - pipe outer diameter, mmS - allowable stress of materials, MPa

- Q: What are the advantages of using aluminum pipes?

- There are several advantages of using aluminum pipes. Firstly, aluminum pipes are lightweight, making them easier to handle and transport compared to other metals such as steel. Secondly, aluminum is corrosion-resistant, ensuring that the pipes have a longer lifespan and require less maintenance. Additionally, aluminum pipes have excellent heat conductivity, making them suitable for applications that involve heat transfer. Lastly, aluminum is a highly recyclable material, making it an environmentally friendly choice.

- Q: Can aluminum pipes be used for irrigation pumps?

- Certainly! Irrigation pumps can indeed utilize aluminum pipes. Renowned for their lightweight nature, durability, and resistance to corrosion, aluminum pipes prove to be a fitting option for irrigation systems. Their exceptional flexibility permits effortless installation and maintenance procedures. Moreover, their commendable heat conductivity aids in effectively dissipating heat from the pump. In summary, aluminum pipes furnish a practical and efficient resolution for irrigation pumps, offering both cost-effectiveness and efficacy.

Send your message to us

Aluminum Pipes for Building Aluminum Profiles

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords