Aluminum Profiles for Solar Panel Frame - Aluminium Profile Extrusion 6063

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

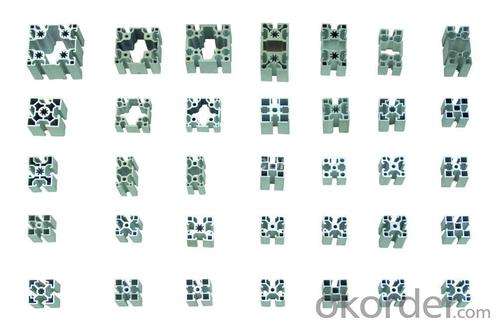

Aluminum Profile

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: What unique considerations or criteria must be met when installing aluminum profiles to ensure they are correctly installed?

- <p>Yes, there are special requirements for installing aluminum profiles correctly. These include ensuring the profiles are of the correct size and specifications for the intended application, proper alignment to maintain structural integrity, and secure fastening to prevent movement or damage. Additionally, it's crucial to follow the manufacturer's guidelines for installation, which may include specific torque settings for screws or bolts, and to consider environmental factors such as temperature and humidity that could affect the profile's performance over time. Proper installation also involves checking for any damage or defects in the profiles before installation and ensuring that all components are compatible with each other.</p>

- Q: How much is aluminum freight per kilometer per ton?

- China Logistics Network: batch transportation more than 30 tons, 40 yuan per ton per ton

- Q: What specific coatings or finishes are necessary for aluminum profiles to withstand cold weather conditions?

- <p>In cold climates, aluminum profiles may require special coatings or finishes to enhance durability and resistance to corrosion. These can include anodizing, which forms a protective oxide layer on the aluminum surface, or powder coating, which provides a hard, durable finish. Additionally, thermal breaks may be incorporated into the design to reduce heat transfer and prevent condensation. It's crucial to select the right finish based on the specific environmental conditions and the intended use of the aluminum profile.</p>

- Q: Are aluminum profiles resistant to impact?

- Yes, aluminum profiles are generally resistant to impact. Aluminum is known for its high strength-to-weight ratio, meaning it is strong and durable while still being lightweight. This makes it an excellent choice for applications where impact resistance is important, such as in the construction industry for window frames, doors, and curtain walls. Additionally, aluminum profiles can be further enhanced with various surface treatments and coatings to improve their impact resistance even more. However, it is worth noting that the specific impact resistance of an aluminum profile can vary depending on its thickness, design, and any additional reinforcements that may be used.

- Q: 5002 and 6063 aluminum profiles difference

- 6063 aluminum alloy main alloy elements for magnesium and silicon, with excellent processability, excellent weldability, extrusion and electroplating, good corrosion resistance, toughness, easy polishing, coating, anode oxidation effect is excellentIt is a typical extrusion alloy, widely used in building profiles, irrigation pipes, tubes, rods and profiles for vehicles, platforms, furniture, elevators, fences, etc.

- Q: Top 10 ranking enterprises of aluminum profiles in China

- 1, aluminum, aluminum (China Aluminum Group, China's aluminum profile ten enterprises, the central management of large state-owned enterprises)2 Asia - South Asia (China well-known trademark, China famous brand, China aluminum enterprise ten, Guangdong Asia Aluminum Factory Co., Ltd.)3 Jianmei aluminum (A Well-Known Trademark in China, Chinese brand, China aluminum enterprise ten, Guangdong Jianmei Aluminum Profile Factory Co., Ltd.)4 Fenglv aluminum material (A Well-Known Trademark in China Chinese, famous brand, famous brand in Guangdong Province, Guangdong famous brand, Guangdong Feng Aluminum Co. Ltd.)5 Zhong Wang aluminum (China famous brand, China well-known trademark, Liaoning famous brand products, China Zhong Wang Holdings Limited)6 (China Hing Fat aluminum brand, A Well-Known Trademark in China, China aluminum enterprise ten, Xingfa Aluminum Holdings Limited)7 Nanshan aluminum (China famous brand, China well-known trademark, China aluminum enterprise ten, Shandong Nanshan aluminum Limited by Share Ltd)8 Zhensheng aluminum (famous brand, China aluminum top ten enterprises, Changsha Shinn Plastic Group Co. Ltd.)9, the court aluminum (China well-known trademarks, China aluminum profile ten enterprises, the court aluminum Polytron Technologies Inc)10 pillars of new materials (China famous brand, China Aluminum ten, Zhejiang pillars, new material Limited by Share Ltd)

- Q: Can aluminum profiles be used in the construction of modular buildings?

- Yes, aluminum profiles can be used in the construction of modular buildings. Aluminum profiles are lightweight, yet strong and durable, making them an ideal material for modular construction. They can be easily fabricated and joined together, allowing for flexibility in design and construction. Additionally, aluminum profiles have excellent corrosion resistance, which is crucial for modular buildings that may be exposed to various weather conditions. The use of aluminum profiles in modular construction can also contribute to sustainability, as aluminum is a highly recyclable material. Overall, aluminum profiles offer numerous advantages for the construction of modular buildings, making them a popular choice in the industry.

- Q: Can aluminum profiles be utilized in creating distinctive architectural designs and styles?

- <p>Yes, aluminum profiles can be used to create unique architectural designs and styles. They are favored for their strength, durability, and versatility. Architects can manipulate aluminum to achieve a wide range of shapes and structures, from sleek modern designs to traditional styles with a contemporary twist. Aluminum's lightweight nature and resistance to corrosion make it an ideal material for both interior and exterior applications, allowing for creative freedom in architectural expression.</p>

- Q: Is it possible to utilize recycled aluminum extrusions in a construction project to lessen the environmental footprint?

- <p>Yes, using recycled aluminum extrusions in your building project can significantly reduce environmental impact. Recycled aluminum requires less energy to produce compared to new aluminum, reducing greenhouse gas emissions. It also conserves natural resources by decreasing the need for mining. Additionally, incorporating recycled materials can contribute to a project's sustainability goals and potentially qualify for green building certifications, enhancing the building's marketability and appeal.</p>

- Q: What kind of equipment are needed for the production of aluminum profiles?

- Upstairs is a very comprehensive aluminum factory ~!Basic ~!1, casting furnace, do not engage, you can also buy aluminum rod production;2. Extruder;3, aging furnace, used to increase the hardness of aluminum profiles;4. Anodic oxidation line;5, other, double head saw, roll bending machine, forklift, crane and other basic equipment needed for the production.

Send your message to us

Aluminum Profiles for Solar Panel Frame - Aluminium Profile Extrusion 6063

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords