Delemar Aluminium Profile Construction and Industry

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

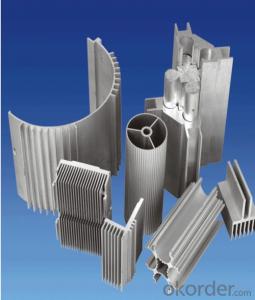

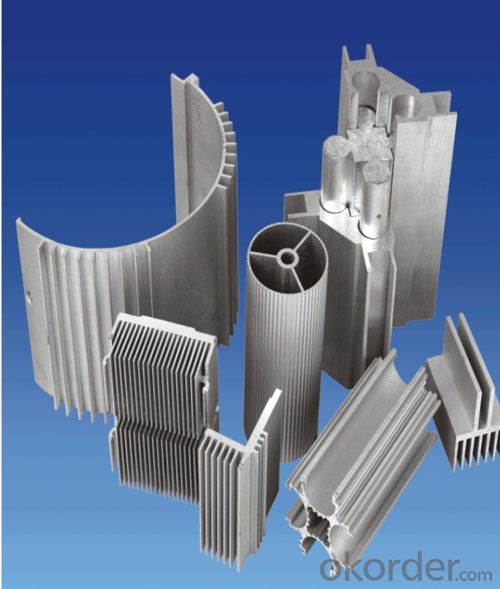

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: It is now the most urban rail trains, as well as the manufacturing methods and processes of large parts profiles used in the manufacture of CRH3 type emus.

- Extrusion; preheating; mold preheating; extrusion quality inspection (optical projection measurement); cutting; heat treatment; quality assurance tests; mechanical properties; cross sectional metallography; electrical conductivity) shipment..

- Q: What are the different finishing options available for aluminum profiles?

- The different finishing options available for aluminum profiles include anodizing, powder coating, painting, polishing, brushing, and sandblasting. These options allow for customization in terms of color, texture, and durability. Anodizing provides a protective layer and can be done in various colors. Powder coating offers a wide range of colors and a durable finish. Painting allows for custom colors and designs. Polishing creates a smooth and reflective surface. Brushing creates a brushed metal look. Sandblasting adds texture and can create a matte or satin finish. Overall, these finishing options enhance the aesthetics and functionality of aluminum profiles.

- Q: Can aluminum profiles be bent or shaped?

- Aluminum profiles possess the capability of being bent or shaped in various ways. As a metal, aluminum is incredibly versatile and pliable, enabling it to effortlessly adopt numerous shapes and configurations. The procedure of bending or shaping aluminum profiles entails the application of heat and force to the metal, allowing it to be manipulated to one's desired form. This adaptability renders aluminum profiles exceptionally suitable for a wide array of industries, including construction, automotive, and aerospace, which demand materials that are both lightweight and durable. Moreover, aluminum profiles can also undergo extrusion, a process involving the metal being pushed through a die to create a specific shape or cross-section. All in all, the capacity to bend and shape aluminum profiles establishes them as a highly favored choice across various industries.

- Q: How does the aluminum profile bevel come round?

- If the stitching aluminum alloy model is the same, then the cutting angle must be 45 degrees, it is possible to splice.

- Q: This question asks for methods to prevent aluminum profiles from rusting during the transportation process.

- <p>To prevent rusting of aluminum profiles during transportation, ensure proper packaging with moisture-resistant materials. Use protective films or covers to shield the profiles from direct contact with moisture and humidity. Maintain a controlled environment in the transport vehicle, avoiding high humidity and condensation. Regularly inspect the profiles for any signs of moisture or damage and address them promptly. Additionally, consider using rust inhibitors or anti-corrosion coatings on the aluminum profiles before packaging. Always handle the profiles with care to avoid scratches or damage that could lead to rusting.</p>

- Q: Can aluminum profiles be used in the production of food processing equipment?

- Aluminum profiles are indeed applicable in the production of food processing equipment. They possess a number of advantages for this purpose due to their lightweight and versatile nature. Their non-toxic and non-corrosive properties make them an ideal option for use in food processing environments where hygiene is of utmost importance. Moreover, aluminum profiles can be effortlessly cleaned, exhibit high resistance to chemicals, and remain unaffected by moisture or humidity. In addition, aluminum serves as an efficient heat conductor, which is crucial for ensuring effective food processing. Furthermore, it boasts exceptional structural strength and can be easily fabricated to produce customized equipment. Overall, aluminum profiles are widely favored in the food processing industry owing to their enduring nature, versatility, and hygienic attributes.

- Q: Inquire if aluminum profiles can be recycled locally or regionally and how to find more information about it.

- <p>Yes, aluminum profiles can be recycled both locally and regionally. Recycling aluminum is an efficient process that conserves resources and energy. To find out more about local recycling options for aluminum profiles, you can: 1) Contact your local waste management or recycling center to inquire about their services. 2) Search online for recycling facilities in your region that specialize in aluminum. 3) Reach out to local metal scrapyards, as they often accept aluminum for recycling. 4) Check with local environmental agencies or non-profit organizations focused on recycling for guidance and resources.</p>

- Q: Can aluminum profiles be used in warehouse and storage systems?

- Yes, aluminum profiles can be used in warehouse and storage systems. Aluminum profiles are lightweight, durable, and corrosion-resistant, making them ideal for use in storage systems such as shelves, racks, and pallets. Additionally, aluminum profiles can be easily customized and assembled, allowing for efficient and flexible storage solutions in warehouses.

- Q: What are the different surface finishing options available for aluminum profiles?

- There are several surface finishing options available for aluminum profiles, each offering different benefits and aesthetic appearances. Some of the commonly used surface finishing options for aluminum profiles include: 1. Anodizing: Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum. This process not only enhances corrosion resistance but also provides a variety of color options. Anodized aluminum profiles are durable, easy to maintain, and have a smooth, attractive finish. 2. Powder Coating: Powder coating involves applying a dry powder to the surface of the aluminum profile and then curing it under heat. This process creates a tough, decorative finish that is resistant to chipping, scratching, and fading. Powder coating offers a wide range of color options and can be customized to achieve different textures and effects. 3. Polishing: Polishing is a mechanical process that creates a high-gloss, reflective finish on the aluminum profile. It involves using abrasives and polishing compounds to remove surface imperfections and achieve a smooth, mirror-like appearance. Polished aluminum profiles are commonly used in decorative applications where a sleek and shiny finish is desired. 4. Brushing: Brushing involves using abrasive brushes or pads to create a textured, brushed finish on the aluminum profile. This process produces parallel lines or circular patterns on the surface, giving it a unique and stylish appearance. Brushed aluminum profiles are often used in architectural and interior design applications. 5. Electrophoretic Coating: Electrophoretic coating, also known as e-coating, is an immersion process where an electrically charged paint is applied to the aluminum profile. This process ensures uniform coating thickness and excellent corrosion resistance. E-coating provides a smooth, even finish and is commonly used in automotive and industrial applications. 6. Wood Grain Effect: Aluminum profiles can be treated with a special coating to mimic the appearance of wood grain. This option is popular in architectural applications where the durability and low maintenance of aluminum are preferred over natural wood. These are just a few of the surface finishing options available for aluminum profiles. The choice of finishing method depends on the desired appearance, functionality, and intended application of the aluminum profile.

- Q: How do aluminum profiles compare to other types of materials?

- Compared to other materials, aluminum profiles possess several advantages. Firstly, their lightweight nature is well-known, making them easier to handle and transport. This quality is particularly advantageous in industries where weight reduction is crucial, such as aerospace and automotive sectors. Secondly, aluminum profiles exhibit excellent resistance to corrosion. Unlike materials like steel or iron, aluminum does not rust when exposed to moisture or other corrosive elements. This makes aluminum profiles ideal for outdoor applications or in environments where moisture is present, such as marine or coastal areas. Furthermore, aluminum profiles have a high strength-to-weight ratio, meaning they are relatively strong while remaining lightweight. This attribute allows for the utilization of aluminum in various structural applications, where strength is important but weight reduction is also desired. Moreover, aluminum profiles are highly versatile and can be easily extruded into different shapes and sizes to meet specific design requirements. This flexibility permits customization and adaptability in various industries, including construction, transportation, and industrial manufacturing. Lastly, aluminum is an incredibly sustainable material. It is 100% recyclable, meaning it can be melted down and reused without any loss in quality. This contributes to the reduction of environmental impact and promotes a circular economy. In conclusion, aluminum profiles offer a combination of lightweight properties, corrosion resistance, strength, versatility, and sustainability, making them a favorable choice over other materials in numerous applications.

Send your message to us

Delemar Aluminium Profile Construction and Industry

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords