High Gloss Aluminum Foil Individual Sheets Prepainted Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Prepainted Coil with Hight Gloss Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Prepainted Coil with Hight Gloss:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

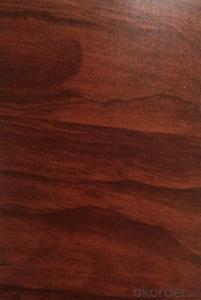

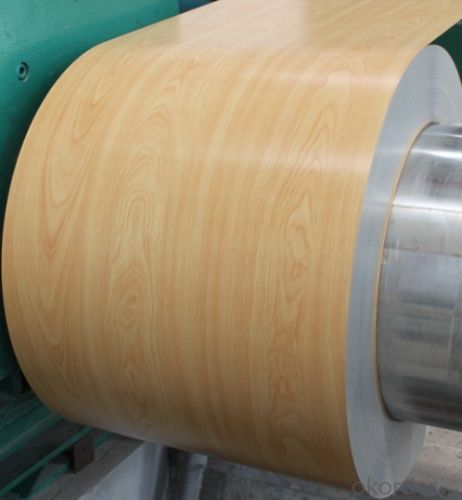

Images of the Aluminium Prepainted Coil with Hight Gloss:

Aluminium Prepainted Coil with Hight Gloss Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Prepainted Coil with Hight Gloss:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: write a balanced equation for the reaction between aluminium metal and potassium hydroxide in water

- Potassium Aluminum Hydroxide

- Q: Are the aluminum sheets suitable for manufacturing lightweight structures?

- Indeed, aluminum sheets are exceptionally well-suited for the production of lightweight structures. Renowned for its low density, aluminum stands as one of the most lightweight metals on the market. This attribute renders aluminum sheets an exceptional option for a multitude of sectors that prioritize weight reduction, such as aerospace, automotive, and construction industries. Furthermore, aluminum boasts an impressive strength-to-weight ratio, enabling it to withstand substantial loads while remaining lightweight. Moreover, aluminum sheets exhibit exceptional corrosion resistance, rendering them suitable for both outdoor and marine applications. All in all, the combination of its lightness, strength, and durability positions aluminum sheets as the preferred choice for the production of lightweight structures.

- Q: What are the common sizes of aluminum sheet?

- Some common sizes of aluminum sheet include 4x8 feet (48x96 inches), 4x10 feet (48x120 inches), and 5x10 feet (60x120 inches).

- Q: What are the different alloy compositions available for aluminum sheets?

- Aluminum sheets offer a variety of alloy compositions, each with its own distinct properties and applications. There are several common alloy compositions to consider. Firstly, we have 1100, which stands out for its exceptional corrosion resistance and high thermal conductivity. This alloy finds its place in chemical equipment, heat exchangers, and food processing equipment. Next, 3003 presents good formability, moderate strength, and excellent corrosion resistance. It is commonly employed in packaging, tanks, and architectural applications. Moving on to 5052, this alloy boasts high strength and good formability. It is often utilized in marine applications, as well as in aircraft and automotive parts. For those seeking excellent strength, good formability, and high corrosion resistance, 6061 is the alloy of choice. It is commonly found in structural applications like bridges, buildings, and transportation equipment. Lastly, we have 7075, known for its remarkably high strength and good machinability. Aerospace applications, as well as high-stress parts in the automotive and sporting goods industries, benefit from this alloy. These examples merely scratch the surface of the numerous alloy compositions available for aluminum sheets. The selection of the appropriate alloy hinges on specific application requirements, such as strength, corrosion resistance, formability, and machinability.

- Q: What is the cost of aluminum sheets?

- The cost of aluminum sheets can vary depending on factors such as size, thickness, and quantity. It is best to check with suppliers or retailers for current pricing information.

- Q: Can aluminum sheets be hydroformed?

- Yes, aluminum sheets can be hydroformed.

- Q: What are the different types of finishes available for painted aluminum sheets?

- There are several types of finishes available for painted aluminum sheets, including matte, satin, glossy, metallic, and textured finishes. These finishes provide different levels of sheen, texture, and visual appeal, allowing for a wide range of aesthetic options for various applications.

- Q: Can aluminum sheets be bent?

- Yes, aluminum sheets can be bent. Aluminum is a highly malleable metal, which means it can be easily shaped or formed using techniques such as bending, rolling, or folding. The process of bending aluminum sheets involves applying force to the metal in order to create a desired angle or curve. This can be done by using specialized tools such as a brake press or by using manual techniques. The flexibility of aluminum makes it a popular choice for various applications where bending or shaping is required, such as in construction, automotive, or aerospace industries.

- Q: Are aluminum sheets resistant to abrasion?

- Yes, aluminum sheets are generally resistant to abrasion due to their hardness and durability.

- Q: What is the shear strength of 101 aluminum sheets?

- The shear strength of 101 aluminum sheets depends on various factors such as thickness, temper, and manufacturing process. Without specific information, it is challenging to provide an accurate answer.

Send your message to us

High Gloss Aluminum Foil Individual Sheets Prepainted Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords