Aluminum Roofing Sheets in Kerala for Building Decorations in Sheet Form

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Aluminium in Sheet Form for Building Decorations Description

Aluminium in Sheet Form for Building Decorations is one semi-finished aluminium material. It is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminium in Sheet Form for Building Decorations

Aluminium in Sheet Form for Building Decorations | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminium in Sheet Form for Building Decorations

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminium in Sheet Form for Building Decorations

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminium in Sheet Form for Building Decorations

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

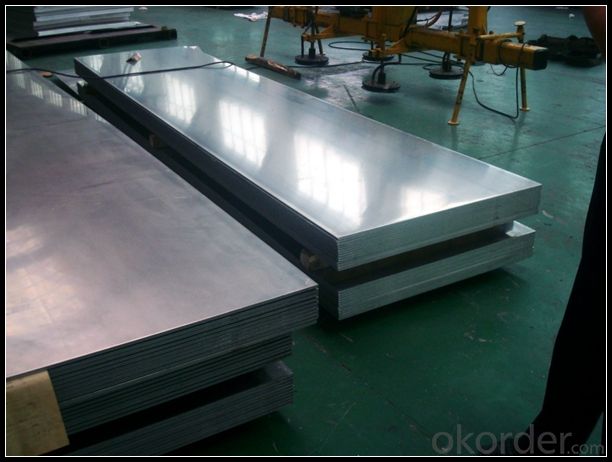

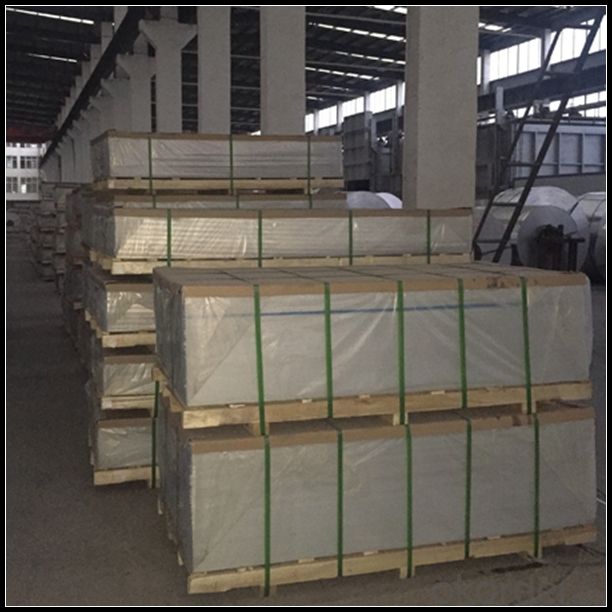

6. Image of Aluminium in Sheet Form for Building Decorations

7. Package and shipping of Aluminium in Sheet Form for Building Decorations

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How do aluminum plates paint?

- Pretreatment is usually required. Acid and alkali cleaning can be done either by oil or by xylene,The paintings do not know, but most of them are painted or printed on the aluminum plate, usually by heat transfer, silk screen, or decorative board, which is sprayed directly and then painted.

- Q: Can aluminum sheets be used for solar panels?

- Yes, aluminum sheets can be used for solar panels. Aluminum is a commonly used material in the construction of solar panels due to its excellent properties. It is lightweight, durable, and corrosion-resistant, making it suitable for withstanding various weather conditions. Additionally, aluminum is a good conductor of electricity, which is essential for efficient energy production in solar panels. The use of aluminum sheets in solar panels helps to ensure their longevity and performance while also reducing the overall weight and cost of the panels.

- Q: Can aluminum sheets be used for protective enclosures?

- Yes, aluminum sheets can be used for protective enclosures. Aluminum is a lightweight yet durable material that offers excellent protection against various environmental factors such as corrosion, moisture, and UV rays. It is commonly used in industries such as automotive, aerospace, and construction for manufacturing enclosures to shield sensitive components or equipment from potential damage.

- Q: How is aluminum sheet made?

- Aluminum sheet is made through a process called rolling, which involves passing a preheated aluminum ingot through a series of rolling mills. The initial step is the heating of the ingot to a specific temperature to make it more malleable. Once heated, the ingot is then passed through a series of rolling mills, where it is continuously pressed and stretched to reduce its thickness and increase its length. The rolling mills consist of a pair of rotating cylinders with grooves on their surfaces. As the ingot passes through these cylinders, it is compressed and elongated, resulting in a thinner and longer sheet. The process is repeated multiple times, with each pass reducing the thickness of the sheet further. To maintain the desired thickness and dimensions, the sheet is periodically annealed, which involves heating it to a specific temperature and then slowly cooling it. This annealing process helps relieve internal stresses and ensures the sheet retains its desired properties. Once the desired thickness is achieved, the aluminum sheet is cooled, trimmed, and cut into specific lengths or rolled into coils for further processing or distribution. The final product is a flat, thin, and versatile sheet of aluminum that can be used in a wide range of applications, from construction and automotive industries to packaging and electrical appliances.

- Q: Are aluminum sheets suitable for roofing?

- Yes, aluminum sheets are suitable for roofing. Aluminum is a popular material for roofing because it is lightweight, durable, and resistant to corrosion. It is also non-combustible, making it a safer option for roofing. Aluminum sheets are easy to install and maintain, and they can withstand harsh weather conditions such as heavy rain, snow, and wind. Additionally, aluminum is a sustainable material, as it is 100% recyclable, making it an environmentally friendly choice for roofing. Overall, aluminum sheets provide a long-lasting and reliable roofing solution for both residential and commercial buildings.

- Q: What is the corrosion resistance of 101 aluminum sheets in saltwater environments?

- 101 aluminum sheets are widely acknowledged to have excellent corrosion resistance in saltwater environments. Aluminum possesses inherent resistance to corrosion and when it encounters saltwater, it develops a protective oxide layer on its surface, which enhances its resistance to corrosion. This oxide layer functions as a shield, obstructing direct contact between the saltwater and the underlying metal, thereby decelerating the corrosion process. Nevertheless, it is crucial to acknowledge that prolonged exposure to saltwater can still result in some level of corrosion over time. Employing regular maintenance and applying protective coatings can significantly augment the corrosion resistance of 101 aluminum sheets in saltwater environments.

- Q: What is the most efficient and low cost method for welding 1mm-3mm aluminum sheet?,What's new?

- Bonding is also good if possible. Now there are many kinds of engineering adhesives, and the strength is good.

- Q: Are the aluminum sheets suitable for manufacturing aircraft wings?

- Indeed, aluminum sheets prove to be a fitting material for the production of aircraft wings. In the aerospace sector, aluminum is extensively utilized owing to its remarkable strength-to-weight ratio, ability to resist corrosion, and high thermal conductivity. These attributes render it an ideal option for fabricating aircraft components that are both lightweight and robust, such as wings. Aluminum sheets can be easily molded, fused, and processed, enabling the creation of intricate wing designs. Furthermore, the low density of aluminum aids in reducing the overall weight of the aircraft, thereby enhancing fuel efficiency and maneuverability. In summary, the utilization of aluminum sheets in the manufacture of aircraft wings is a prevalent and validated practice within the aviation industry.

- Q: Can aluminum sheets be used for packaging?

- Aluminum sheets have the ability to be utilized for packaging purposes. The packaging industry highly values aluminum due to its numerous advantageous properties, as it is a versatile and extensively used material. The lightweight nature, strength, durability, and resistance to corrosion of aluminum make it an optimal choice for packaging applications. By using aluminum sheets, it is effortless to mold them into various shapes and sizes, offering the advantage of design flexibility and customization. In addition, aluminum possesses impermeability to light, moisture, gases, and microorganisms, guaranteeing the safety and preservation of the packaged goods. Its exceptional heat conductivity also allows for efficient heat transfer during processes like sterilization or pasteurization. Moreover, aluminum is environmentally friendly as it can be recycled, making it a sustainable option for packaging. All in all, aluminum sheets are a remarkable choice for packaging purposes due to their exceptional properties and versatility.

- Q: Are aluminum sheets suitable for use in marine or saltwater environments?

- Aluminum sheets are indeed appropriate for utilization in marine or saltwater settings. Aluminum boasts exceptional resistance to corrosion and is renowned for its capacity to endure the challenging conditions present in marine environments. In contrast to numerous other metals, when aluminum is exposed to oxygen, it forms a shielding oxide layer on its surface, which aids in thwarting further corrosion. This oxide layer serves as a barrier, shielding the underlying metal from saltwater and other detrimental elements. Furthermore, aluminum is both lightweight and robust, rendering it an optimal selection for marine applications that prioritize weight reduction. It is commonly employed in the construction of boats, ships, offshore structures, and various other marine apparatus.

Send your message to us

Aluminum Roofing Sheets in Kerala for Building Decorations in Sheet Form

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords