Aluminum Roofing Sheets in Kerala - Aluminium Cold Rolled Sheet in Our Warehouse with Better Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

CNB, INTERNATIONAL CORPORATION'S Aluminum sheet is widely used in the field of industrial construction field and decoration field, etc.

There are many different alloy nubmer: 6000 series,7000series, 8000 series, etc. The detailed grade are as follows: 1010,1100, 2024, 3003, 5052,5754,6061,6063,8011, etc.

The temper is include H14, H24, F ,O, H112, H112, H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

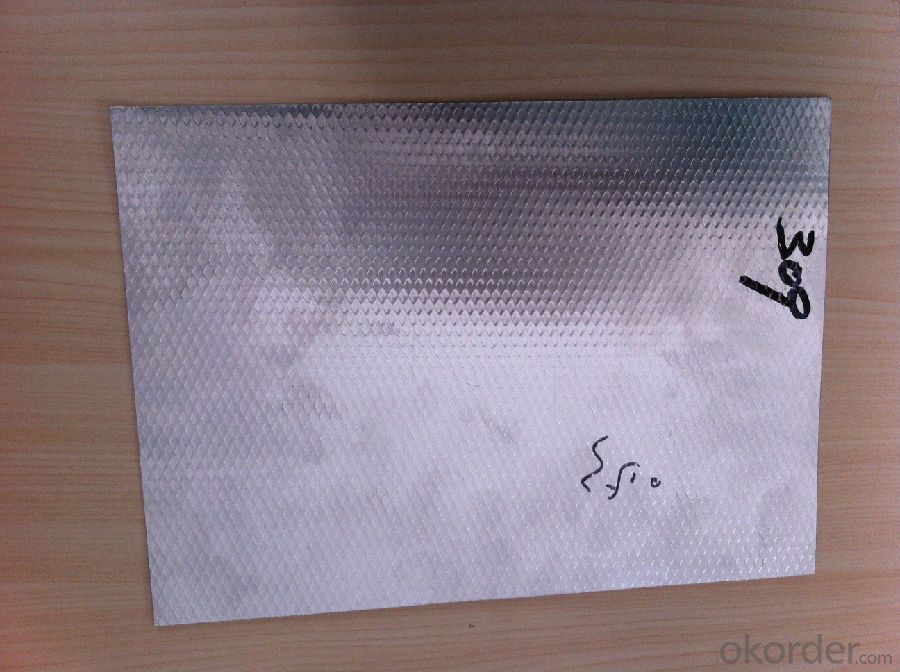

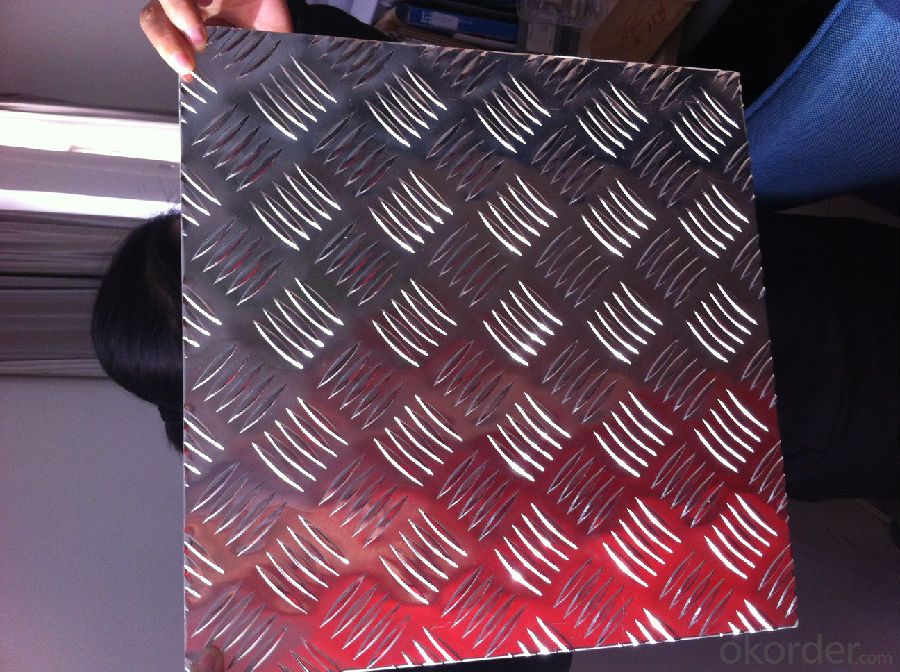

3. Image.

4. Product detailed sizes:

1000mm*2000mm,1219mm*2438mm,500MM*500MM,1000*1000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 500mm to 2500mm, etc.

What is the length range:

---It is from 1000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 14 tons/each size.

How manyound 10000 tons totally.

Where is your client from?

---Normally it is from Pakistan,Saudi Arabia, BANGLADESH,PAKISTAN,FIJI, England,Turkey,etc.

What is your mainly products?

---Normally they are aluminum sheet,big-5-bar aluminium checkered sheet,small-5-bar aluminium checkered sheet,mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: I've narrowed down my next bike next year to either the cannondale Caad10 Ultegra version or the supersix 105 version, I've heard good things about both bikes, and at this point its gonna be down to preference after I ride it but, is aluminum stronger than carbon or vice versa? Will carbon crack easily or fail catastrophically?

- Carbon fiber and aluminum are newer and increasingly popular substitutes for the original bike frame material, steel. In the early 21st century, carbon fiber gained a reputation for being lightweight and the latest frame technology, but advancements in aluminum alloys and frame construction make the two frame materials equal contenders for best material. Almost all carbon fiber bicycles are designed for competitive road riders, who can get increased speed from riding on such a lightweight material. In contrast, aluminum frames are available for road, mountain, cyclocross, hybrid and other models of bikes as they come in different grades. Carbon fiber frames are not always lighter than aluminum frames. Weight depends on construction methods. According to outdoor equipment retailer REI, when it comes to bike frames, the more you pay, the less it weighs, and this holds true for carbon fiber and aluminum bikes. Compare two bikes of any frame material, and the lighter one will cost less. Due to the weight forces operating on a loaded-down touring bike, carbon fiber is a poor choice for such trips, as well as for any sort of off-road riding or trick riding. Lance Armstrong notes that the areas where metal fittings, such as fork ends, bottom bracket shells or headsets, attach to a carbon fiber frame are particularly weak. Carbon fiber is excellent for racing, with its combination of durability and weight. Aluminum frames handle better the weight and shocks of grocery shopping, commuting and trail riding.

- Q: Is it possible to utilize aluminum sheets as a material for constructing roofs?

- <p>Yes, aluminum sheets can be used for roofing materials. They are known for their durability, lightweight, and resistance to corrosion. Aluminum is also energy-efficient, reflecting heat and reducing cooling costs. It's recyclable and has a long lifespan, making it an environmentally friendly choice. However, it may not be as impact-resistant as some other materials and can be more expensive upfront.</p>

- Q: What is the maximum temperature that aluminum sheets can withstand?

- The maximum temperature that aluminum sheets can tolerate relies on various factors, including the composition of the alloy, thickness, and intended purpose. Generally, aluminum has a melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit). Nevertheless, aluminum sheets can typically endure significantly higher temperatures without melting or distorting. Regarding most commercially available aluminum alloys, the maximum temperature for continuous utilization varies from 200 to 300 degrees Celsius (390 to 570 degrees Fahrenheit). Beyond this range, the material might begin to display reduced strength and heightened vulnerability to deformation or harm. Nevertheless, it is crucial to mention that the precise maximum temperature limit for a specific aluminum sheet should be determined by referring to the manufacturer's specifications or conducting specific testing. Factors like the presence of coatings or surface treatments, exposure to prolonged heat, and thermal cycling can also influence the maximum temperature tolerance of aluminum sheets.

- Q: What are the common thicknesses available for aluminum sheets?

- The available thickness options for aluminum sheets vary depending on the specific application and industry requirements. Some commonly found thicknesses for aluminum sheets include 0.025 inches (0.635 mm), 0.032 inches (0.81 mm), 0.040 inches (1.02 mm), 0.050 inches (1.27 mm), 0.063 inches (1.6 mm), 0.080 inches (2.03 mm), 0.090 inches (2.29 mm), 0.125 inches (3.18 mm), 0.190 inches (4.83 mm), and 0.250 inches (6.35 mm). These thicknesses see frequent usage in industries such as construction, automotive, aerospace, and manufacturing. It should be noted, however, that specialized applications may require custom orders or fabrication to meet specific thickness requirements.

- Q: How do I prevent corrosion on aluminum sheets?

- To prevent corrosion on aluminum sheets, there are a few steps you can take: 1. Clean the aluminum sheets regularly: Use a mild detergent or aluminum cleaner to remove any dirt, grime, or chemical residues that may be present on the surface. This will prevent the buildup of corrosive substances. 2. Apply a protective coating: Consider applying a protective coating on the aluminum sheets. There are various types of coatings available, such as clear coats, anodizing, or painting. These coatings act as a barrier between the aluminum and the surrounding environment, preventing corrosion. 3. Avoid contact with corrosive substances: Aluminum can be susceptible to corrosion when it comes into contact with certain chemicals, such as acids, alkalis, or saltwater. Be mindful of the environment in which the aluminum sheets are stored or used and avoid exposure to these corrosive substances. 4. Use proper storage methods: Store aluminum sheets in a dry environment with low humidity levels. Moisture can accelerate the corrosion process, so it's important to keep the sheets dry and protected from excessive moisture. 5. Implement preventive measures: Consider using corrosion inhibitors or anti-corrosion sprays specifically designed for aluminum. These products can provide an extra layer of protection against corrosion, especially in harsh or corrosive environments. By following these preventive measures, you can significantly reduce the risk of corrosion on aluminum sheets and prolong their lifespan.

- Q: What is the cost of aluminum sheet compared to other metals?

- The cost of aluminum sheet compared to other metals can vary depending on various factors such as market conditions, availability, and specific metal grades. Generally, aluminum sheet is considered to be more affordable than many other metals such as stainless steel, copper, and brass. This is mainly due to the abundance of aluminum in the Earth's crust and the relatively low cost of extracting and refining it. Additionally, aluminum is often lighter in weight compared to other metals, making it a more cost-effective option for applications where weight is a concern, such as in the transportation industry. However, it is important to note that the cost of aluminum can fluctuate based on global supply and demand dynamics, tariffs, and other economic factors. Therefore, it is recommended to check current market prices and consult with suppliers or metal specialists for accurate and up-to-date pricing information.

- Q: Can aluminum sheets be used for industrial shelving?

- Yes, aluminum sheets can be used for industrial shelving. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for various industrial applications, including shelving. It offers strength and stability while being easy to clean and maintain. Additionally, aluminum's versatility allows for customization and modification to fit specific storage needs.

- Q: How do you protect aluminum sheets from scratches?

- To protect aluminum sheets from scratches, there are a few steps you can take: 1. Handle with care: When handling aluminum sheets, always be mindful of their vulnerability to scratches. Avoid dragging or sliding them across rough surfaces, as this can cause scratches. Instead, lift and place them gently, ensuring you have a clean, smooth surface to work on. 2. Use protective covering: Before storing or transporting aluminum sheets, consider using a protective covering such as a plastic film or paper. This will provide a barrier and prevent direct contact with other surfaces, reducing the risk of scratches. Ensure that the covering is clean and free from any dirt or debris. 3. Store in a safe environment: When not in use, store aluminum sheets in a clean and dry environment. Avoid storing them alongside abrasive materials or objects that could potentially scratch them. Additionally, consider using dividers or separators to create individual compartments for each sheet, preventing them from rubbing against each other. 4. Clean with caution: When cleaning aluminum sheets, use a soft, non-abrasive cloth or sponge. Avoid using wire brushes or rough materials that can cause scratches. Additionally, use a mild detergent or aluminum cleaner specifically designed for this purpose. Rinse thoroughly and dry the sheets completely to prevent any moisture from causing damage. 5. Apply a protective coating: Another option to protect aluminum sheets from scratches is to apply a protective coating. There are various types of coatings available, such as clear lacquers or specialized aluminum protectants. These coatings create a thin barrier on the surface of the aluminum, adding an extra layer of protection against scratches. By following these steps, you can significantly reduce the risk of scratches on your aluminum sheets and help maintain their appearance and integrity over time.

- Q: I'd like to have the aluminum on the etching front white. Do any of the experts know that?

- After anodizing, it turns white. If not, the aluminum plate should be white and spray polyester or fluorocarbon paint,

- Q: What is the fatigue life of aluminum sheets?

- The endurance capacity of aluminum sheets pertains to the number of cycles the material can endure before failure arises under cyclic loading circumstances. Various factors, including the composition, thickness, surface finish, loading conditions, and environmental elements, can cause the endurance capacity of aluminum sheets to differ. Aluminum is renowned for its relatively high fatigue strength in comparison to other materials, rendering it a favored option in industries like aerospace, automotive, and construction. The endurance capacity of aluminum sheets is typically influenced by the presence of microstructural flaws, such as inclusions, voids, and grain boundaries. Fatigue tests are conducted, utilizing standardized procedures like ASTM E466 or ASTM E606, to ascertain the endurance capacity of aluminum sheets. These tests entail subjecting the material to cyclic loading conditions, usually at a consistent stress or strain amplitude, while monitoring the number of cycles required for failure to arise. The outcomes are then employed to generate an S-N curve, which represents the connection between the applied stress or strain amplitude and the number of cycles until failure. The S-N curve furnishes valuable insights into the endurance capacity of aluminum sheets, indicating the stress or strain levels at which the material can withstand a specific number of cycles before failure. It is crucial to note that the endurance capacity of aluminum sheets can be enhanced through various approaches, such as alloying, heat treatment, surface treatment, and appropriate design considerations. To conclude, the endurance capacity of aluminum sheets plays a pivotal role in the design of components or structures exposed to cyclic loading conditions. By comprehending the specific properties and characteristics of the aluminum alloy, coupled with proper testing and analysis, it is possible to ascertain the endurance capacity and guarantee the safe and dependable performance of aluminum sheets in diverse applications.

Send your message to us

Aluminum Roofing Sheets in Kerala - Aluminium Cold Rolled Sheet in Our Warehouse with Better Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords