Aluminum Coil Metal Lowes - Aluminium Foil (HHF, Waterproof Foil) / Aluminum Film from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Foil/ Waterproof foil

1) Alloy | AA1050, AA1060, AA1070, AA1100, AA3003, AA3004, AA3105, AA5005, AA5052, AA8011, AA8079 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum |

7) Coil Inner diameter | 76mm, 152mm, or as required |

2. Application of Aluminum Foil/ Waterproof foil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts.

3. Feature of Aluminum Foil/ Waterproof foil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate of Aluminum Foil/ Waterproof foil:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

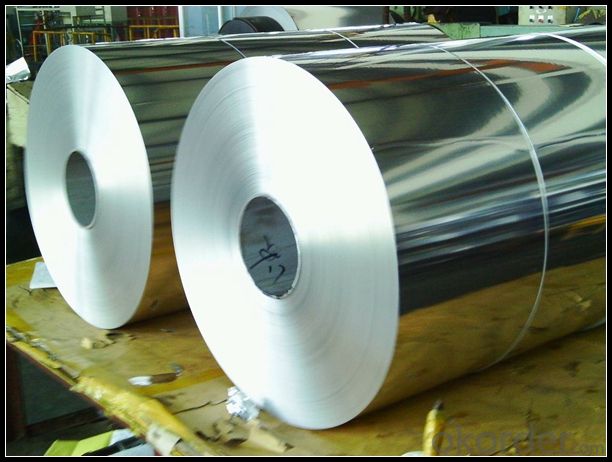

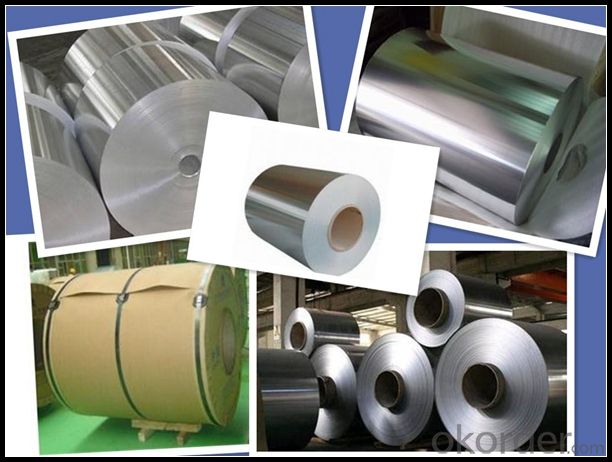

5. Image of Aluminum Foil/ Waterproof foil

6. About Our Company

CNBM International Corp., established in 2004, is the business entity for trade and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 25 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe etc

4)What are your payment terms?

We accept L/C, D/A, D/P, T/T, West Union,etc.

- Q: What are the transportation and storage requirements for aluminum coils?

- Transportation and storage requirements for aluminum coils depend on several factors. Firstly, it is important to handle the coils with care during transportation to avoid any damage. They should be packaged securely to prevent any potential scratches, dents, or deformation. The coils should be protected from moisture, as exposure to water or high humidity levels can cause corrosion. During transportation, it is recommended to use appropriate vehicles or containers that can adequately support the weight and dimensions of the aluminum coils. The coils should be properly secured in place to prevent any movement or shifting that could lead to damage. When it comes to storage, it is crucial to store aluminum coils in a clean, dry, and well-ventilated area. Ideally, the storage facility should maintain a stable temperature and humidity level to prevent any adverse effects on the coils. If the coils are stored outdoors, they should be properly covered and protected from direct sunlight, rain, and other weather conditions. Furthermore, it is important to store aluminum coils away from any corrosive materials or chemicals that could potentially cause damage. They should be stored in a manner that prevents contact with other materials, as physical contact can lead to scratching or other forms of damage. Overall, the transportation and storage requirements for aluminum coils involve careful handling, protection from moisture and corrosive materials, proper packaging and securing during transportation, and storage in a clean and suitable environment. By following these guidelines, the integrity of the aluminum coils can be maintained, ensuring their quality and usability.

- Q: Can aluminum coils be used in the production of household appliances?

- Household appliances can indeed utilize aluminum coils in their production. Aluminum, a material known for its lightweight and durable nature, boasts exceptional thermal conductivity, rendering it highly suitable for various appliance applications. Refrigerators, air conditioners, and heat pumps, for instance, greatly benefit from the utilization of aluminum coils. These coils are commonly employed in the condenser and evaporator coils of such appliances, efficiently facilitating heat transfer. Moreover, the corrosion resistance of aluminum coils is pivotal in ensuring the longevity and optimal performance of household appliances. Consequently, owing to their advantageous properties and benefits, aluminum coils remain a favored option in the production of household appliances.

- Q: Can aluminum coils be used for heat recovery systems?

- Yes, aluminum coils can be used for heat recovery systems. Aluminum is a highly conductive material, which makes it an excellent choice for transferring heat. Aluminum coils are often used in heat exchangers and heat recovery systems to efficiently transfer heat from one medium to another. These coils are designed to maximize surface area, allowing for greater heat transfer. Additionally, aluminum is lightweight and corrosion-resistant, making it durable and suitable for various applications in heat recovery systems.

- Q: Aluminum coil Kaiping is out of arc plate, what's the matter?

- Aluminum coil Kaiping need to use "stretch bending straightening machine" to do leveling, before they can be leveled

- Q: Are aluminum coils suitable for solar panel frames?

- Yes, aluminum coils are suitable for solar panel frames. Aluminum is a lightweight and corrosion-resistant material, making it ideal for use in solar panel frames. It is also highly durable and can withstand various weather conditions, ensuring the longevity of the solar panel structure. Additionally, aluminum is easy to work with and offers excellent heat dissipation properties, which is crucial for solar panels as they generate heat during operation. The use of aluminum coils in solar panel frames helps to enhance the overall efficiency and performance of the solar panel system.

- Q: What is the typical electrical resistivity of aluminum coils?

- The typical electrical resistivity of aluminum coils is around 2.65 x 10^-8 ohm-meters.

- Q: Are aluminum coils available in custom sizes?

- Yes, aluminum coils are available in custom sizes.

- Q: I have a electrical project to do, and could save about $300.00 by using aluminum wire since I can get it free, but I have never used aluminum before, and am not sure if it is a good way to go.

- Aluminum wire is relatively safe on it's own. But care must be taken not to join aluminum wire to copper, or to any appliance, or device that is designed only to be connected with copper wire. When you combine aluminum and copper extra heat is produced at the point of connection, and a fire can result. In the 1970's aluminum was being used a lot, but the technology was new, and a lot of stupid mistakes were made. I had a friend who had a fire start in his home because the house was wired with aluminum wire, and an electric baseboard heater that was only designed for copper was installed. You might save a few bucks in wire, but you should know that aluminum wire is less conductive, and it can have a negative effect on your electricity bill in the long run. But you asked if it is safe, and my answer is, for the unskilled on this subject, aluminum wire is absolutely NOT SAFE!

- Q: Can aluminum coils be used in the manufacturing of aircraft parts?

- Yes, aluminum coils can be used in the manufacturing of aircraft parts. Aluminum is a popular choice for aircraft construction due to its desirable properties, such as lightweight, corrosion resistance, and high strength-to-weight ratio. Aluminum coils can be easily shaped into various forms, making them suitable for creating different components of an aircraft, including fuselage panels, wings, and structural parts. These coils can be further processed through techniques like rolling, extrusion, and forming to achieve the desired dimensions and structural integrity required for aircraft parts. Additionally, aluminum's ability to conduct heat and electricity efficiently makes it useful for applications where temperature control and electrical conductivity are important, such as in heat exchangers and electrical wiring systems within an aircraft. Overall, aluminum coils are a versatile and widely used material in the manufacturing of aircraft parts.

- Q: How can you tell the difference between aluminum and other non-magnetic metals, such as what I've heard called, pot-metal?

- Aluminum is very light. Pot metal, also known as white metal, die-cast zinc, or monkey metal,[1] is a slang term that refers to alloys that consist of inexpensive, low-melting point metals used to make fast, inexpensive castings. There is no scientific metallurgical standard for pot metal; common metals in pot metal include zinc, lead, copper, tin, magnesium, aluminium, iron, and cadmium. The primary advantage of pot metal is that it is quick and easy to cast. Due to its low melting temperature no sophisticated foundry equipment is needed and specialized molds are not necessary. It is sometimes used to experiment with molds and ideas before using metals of higher quality. Examples of items created from pot metal include toys, furniture fittings, tool parts, electronics components, and automotive parts.[citation needed] Pot metal can be prone to instability over time, as it has a tendency to bend, distort, crack, shatter, and pit with age.[1] The low boiling point of zinc and the fast cooling of the newly-cast part often allow air bubbles to remain within the cast part, weakening the metal.[1] Many of the components of pot metal are susceptible to corrosion from airborne acids and other contaminants, and the internal corrosion of the metal often causes the decorative plating to flake off.[citation needed] Pot metal is not easily glued, soldered or welded.[1] At one time, pot metal referred to a copper alloy that was primarily alloyed with lead. 67% Cu, 29% Pb 4% Sb and 80% Cu, 20% Pb were common formulations.[2] The primary component of pot metal is zinc, but often the caster adds other metals to the mix to strengthen the cast part, improve the flow of the molten metal, or to reduce cost.[dubious – discuss] With a low melting point of 419 °C (786 °F), zinc is often alloyed with other metals including lead, tin, aluminium and copper.

Send your message to us

Aluminum Coil Metal Lowes - Aluminium Foil (HHF, Waterproof Foil) / Aluminum Film from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords