Aluminum Coils for Household Use, OEM Branding, BBQ and Chocolate Wrapping

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Details: | Standard export packing or following customer's demand |

Delivery Detail: | Within 10-20days or according to the order quantity |

High Quality and Factory Price Aluminum Coil

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.05~10mm |

Width | <1600mm< span=""> |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~27micron(EN ISO-2360:1995) PVDF27 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

Payment | L/C ,T/T |

Specifications | Width: 30cm,38cm,45cm, OEM; Length: 3m-20m, OEM; Thickness: 10mic-20mic(10mic=10um=0.01mm), OEM; Sizes can be customized according to your requirement; |

| Application |

Supermarkets, catering, hotel, airline, restaurants, household, medical,electronic,chocolate wrapping etc;

|

| Characteristic | 1. Use: suitable for the food packing, barbecue; 2. Color: for food only do sliver color; 3. Inner packing : paper roll core; 4. Box with metal cutter; 5. Surface packing: Color box; |

| NOTES | Our factory can quote to you at the specifications that what you want any time. To undertake all kinds of plastic processing operations. Any sizes and packing can be ordered. Good service and reasonable price.

|

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

Our Services

1. Reasonable production arrangement to make delivery very fast;

2. We are able to provide leading tolerances, metallurgical assistance, quick and reliable delivery, samples for new products, etc.

3. We have the strong capability to meet your particular requirement for the products.

4.To guarantee the quality of the products we can meet most of the standards all over the world.

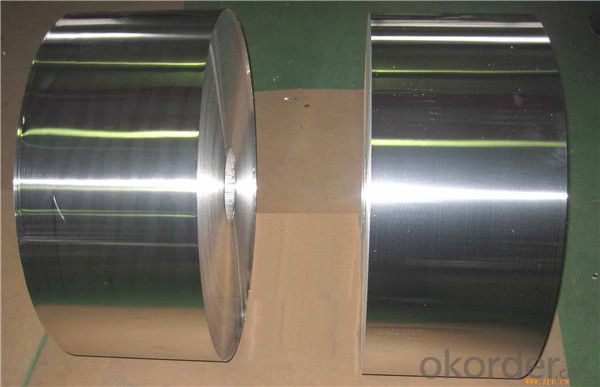

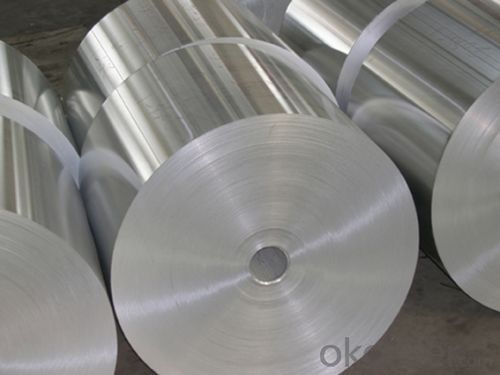

Photos

- Q: How are aluminum coils used in the production of automotive radiators?

- Aluminum coils are used in the production of automotive radiators as they provide excellent heat transfer properties. These coils are typically made from aluminum alloy, which is lightweight, corrosion-resistant, and has high thermal conductivity. The coils are formed into a specific shape and then attached to the radiator's core. As coolant flows through the coils, heat from the engine is transferred to the aluminum, which efficiently dissipates it. This helps in cooling the engine and maintaining its optimal operating temperature. Overall, aluminum coils play a crucial role in enhancing the efficiency and performance of automotive radiators.

- Q: Can aluminum coils be used for industrial piping?

- Yes, aluminum coils can be used for industrial piping. Aluminum is a lightweight and corrosion-resistant material, making it suitable for various industrial applications, including piping systems.

- Q: What are the compositions of aluminum coil coating?

- Resin, pigment, auxiliary and solvent.

- Q: Is it possible to utilize aluminum coils in the creation of decorative objects?

- <p>Yes, aluminum coils can be used for making decorative items. They are lightweight, durable, and corrosion-resistant, making them an excellent choice for various decorative applications. Aluminum's malleability allows it to be easily shaped and bent into different forms, which is ideal for creating intricate designs. Additionally, aluminum can be anodized or painted to achieve a wide range of colors and finishes, enhancing its decorative appeal. Common decorative uses include outdoor furniture, lighting fixtures, and architectural accents.</p>

- Q: Can aluminum coils be used in heat exchangers?

- Yes, aluminum coils can be used in heat exchangers. Aluminum is commonly used in heat exchanger applications due to its excellent heat transfer properties, lightweight nature, corrosion resistance, and cost-effectiveness.

- Q: Is it possible to utilize aluminum coils in the manufacturing of furniture?

- <p>Yes, aluminum coils can be used to make furniture. Aluminum is known for its strength, durability, and resistance to corrosion, making it an ideal material for furniture construction. It is commonly used in outdoor furniture due to its weather resistance. Aluminum coils can be formed into various shapes and sizes to create frames, legs, and other structural components of furniture. Additionally, aluminum's lightweight nature makes it easy to handle and transport, which is beneficial for both manufacturers and consumers.</p>

- Q: Is it possible to utilize an electric iron that features an aluminum coil heater?

- <p>Yes, you can use an electric iron with an aluminum coil heater. Aluminum coil heaters are commonly used in electric irons due to their excellent heat conductivity and quick heat-up time. They distribute heat evenly and maintain a consistent temperature, making them ideal for ironing. However, it's important to follow the manufacturer's guidelines for use and maintenance to ensure safety and longevity of the iron.</p>

- Q: Are aluminum coils suitable for high-gloss applications?

- Aluminum coils are indeed suitable for high-gloss applications. Aluminum has excellent reflective properties and can achieve a high level of shine and gloss when properly treated and finished. The metal's smooth surface and reflective nature allow it to enhance the appearance of high-gloss finishes, making it an ideal choice for applications where a shiny and polished look is desired. In addition to its aesthetic benefits, aluminum also offers several practical advantages for high-gloss applications. It is lightweight, durable, and resistant to corrosion, making it a long-lasting and low-maintenance option. Aluminum coils are also highly malleable, allowing them to be easily formed into various shapes and sizes, which is crucial for achieving the desired high-gloss design. Furthermore, aluminum coils can be coated with a variety of finishes, such as anodized coatings or high-quality paint systems, to enhance their durability and glossiness. These coatings provide an additional layer of protection against scratches, fading, and other forms of wear and tear, ensuring that the high-gloss appearance is maintained over time. In summary, aluminum coils are well-suited for high-gloss applications due to their reflective properties, versatility, and durability. When properly treated and finished, aluminum can provide a stunning and long-lasting glossy finish, making it a popular choice for various industries, including automotive, architecture, and interior design.

- Q: Can aluminum coils be used in the manufacturing of cans?

- Yes, aluminum coils can be used in the manufacturing of cans. Aluminum coils are commonly used in the canning industry as they are lightweight, durable, and provide excellent sealability, ensuring the freshness and preservation of the contents.

- Q: How do aluminum coils contribute to reduced carbon emissions?

- Aluminum coils contribute to reduced carbon emissions in several ways. Firstly, aluminum is a lightweight material compared to other metals, such as steel, which means that less energy is required to transport and handle aluminum coils. This reduced weight results in lower fuel consumption during transportation, ultimately leading to decreased carbon emissions. Additionally, the production of aluminum coils involves significantly less energy compared to other metals. Aluminum is known for its high recyclability, as it can be melted down and reused without losing its original properties. This recycling process requires only a fraction of the energy needed to produce aluminum from raw materials, resulting in reduced greenhouse gas emissions. Furthermore, aluminum coils have excellent thermal conductivity, which allows for improved energy efficiency in various applications. For instance, aluminum coils are commonly used in HVAC systems, where they help transfer heat more effectively, reducing the energy required for heating or cooling. This improved energy efficiency directly translates into lower carbon emissions by reducing the energy demand from power plants. Overall, aluminum coils contribute to reduced carbon emissions through their lightweight nature, recyclability, and improved energy efficiency. By using aluminum coils in various industries, we can minimize the environmental impact, conserve energy resources, and mitigate climate change.

Send your message to us

Aluminum Coils for Household Use, OEM Branding, BBQ and Chocolate Wrapping

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords