Corrugated Aluminum Roofing Sheets - Aluminium Prepainted Sheet - Good Price - High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

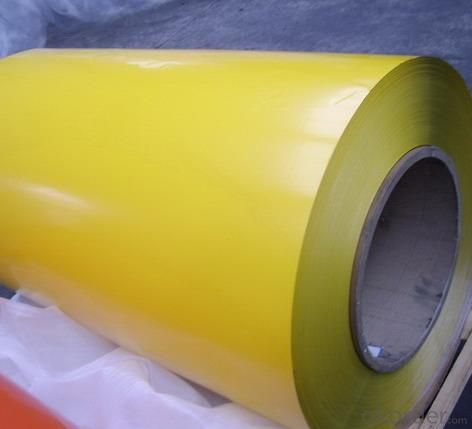

Structure of Prepainted Aluminum Coil Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Prepainted Aluminum Coil:

High intensity

Low welding costs.

Outstanding color compatibility after anodizing

Easy to operate. All-position welding.

Excellent corrosion resistance

Images of Prepainted Aluminum Coil.

Prepainted Aluminum Coil Specification :

| Raw material | SGCC, SPCC, DC51D, SGHC,A653 |

| Certificate | ISO9001.ISO14001.OHSAS18001 |

| Thickness | 0.16mm-0.7mm |

| Width | 1250mm or under |

| Tolerance | thickness+/-0.01mm |

| Surface treatment | galvanized / galvalumized steel sheets |

T Bending (top-coating) T Bending (back-coating) | ≤3T ≤4T |

| Anti-MEK Wiping | ≥100times |

| Zinc coating | 40-180g |

| Type of coating structure | 2/1 or 2/2 coating, or customized |

| Standard | GB/T12754-2006, GB/T9761-1988, GB/T9754-1988, GB/T6739-1996, HG/T3830-2006, HG/T3830-2006, GB/T1732-93, GB/T9286-1998, GB/T1771-1991, GB/T14522-93 |

| Color | customized |

| Application | Building industry ,structural use, roofing, commercial use ,household appliance,industry facilities,office buildings |

FAQ of Prepainted Aluminium Coil:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 5000tons.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

- Q: I am doing a report on machining aluminum and characteristics of aluminum and can not find what the 6061 stock stands for. Looked all over library, internet, etc.

- Death Cab For Cutie's What Sarah Said: And It Came To Me Then That Every Plan Is A Tiny Prayer To Father Time As I Stared At My Shoes In The Icu That Reeked Of Piss And 409 And I Rationed My Breathes As I Said To Myself That I'd Already Taken Too Much Today As Each Descending Peak Of The Lcd Took You A Little Farther Away From Me Away From Me Amongst The Vending Machines And Year-old Magazines In A Place Where We Only Say Goodbye It Stung Like A Violent Wind That Our Memories Depend On A Faulty Camera In Our Minds But I Knew That You Were A Truth I Would Rather Lose Than To Have Never Lain Beside At All And I Looked Around At All The Eyes On The Ground As The Tv Entertained Itself 'cause There's No Comfort In The Waiting Room Just Nervous Pacers Bracing For Bad News And Then The Nurse Comes Round And Everyone Will Lift Their Heads But I'm Thinking Of What Sarah Said That love Is Watching Someone Die

- Q: Is it possible to utilize recycled aluminum to manufacture new items?

- <p>Yes, recycled aluminum can be used to create new products. Aluminum is highly recyclable, and the process of recycling it requires significantly less energy compared to producing aluminum from raw materials. Recycled aluminum maintains the same properties as new aluminum, making it suitable for a wide range of applications, from packaging to construction materials. The use of recycled aluminum helps reduce waste, conserve resources, and lower environmental impact.</p>

- Q: Are the aluminum sheets available in different finishes (e.g., brushed, polished)?

- Yes, aluminum sheets are available in different finishes including brushed and polished. These finishes are achieved through various processes that alter the surface texture and appearance of the aluminum sheets. Brushed finishes create a textured pattern by brushing the surface with fine abrasive materials, resulting in a satin-like appearance. On the other hand, polished finishes involve buffing the surface to a high shine by using abrasive compounds or polishing wheels. These different finishes allow for customization and versatile applications of aluminum sheets in various industries.

- Q: Can aluminum sheet be used for medical applications?

- Yes, aluminum sheet can be used for certain medical applications. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for various medical devices and equipment. For example, aluminum sheets can be used for manufacturing prosthetic limbs, braces, and orthopedic implants. Additionally, aluminum can be used in the production of medical instruments, such as surgical trays, sterilization containers, and imaging equipment. However, it is important to note that aluminum may not be suitable for all medical applications, as certain medical devices may require specific properties or materials to meet regulatory standards and ensure patient safety. Therefore, the use of aluminum sheet in medical applications should be determined on a case-by-case basis, considering the specific requirements and regulations of each application.

- Q: Are aluminum sheets suitable for food contact applications?

- Yes, aluminum sheets are suitable for food contact applications. Aluminum is a non-toxic and non-reactive metal that does not leach harmful substances into food. It is widely used in the food industry for packaging, cooking utensils, and food storage containers. Additionally, aluminum exhibits excellent heat conductivity and can be easily cleaned, making it a popular choice for food-related applications.

- Q: 8mm which type of aluminum plate is suitable for bending?

- How do I calculate the pressure of the seamless steel tube with the outer diameter of 300mm and the thickness of 18mm L=600mm? material

- Q: What are the different methods for finishing the edges of aluminum sheets?

- Depending on the desired outcome and application, there are several approaches to finishing the edges of aluminum sheets. One commonly used method is edge trimming, where excess material is removed from the sheet's edges to achieve a smooth and straight edge. This can be accomplished using various tools like shears, saws, or routers. Another technique is edge deburring, which is employed to eliminate any sharp or rough edges left after cutting. Sanding or grinding tools are often utilized to smooth out the edges and produce a more polished finish. Moreover, edge rolling is a method that can be employed to create rolled or rounded edges on aluminum sheets. This is achieved by using a rolling machine that applies pressure to the edges, bending them into the desired shape. For a more decorative finish, edge profiling can be employed. This involves using specialized tools or machines to craft custom edge shapes or designs on the aluminum sheet. It allows for unique and aesthetically pleasing edges that enhance the overall appearance of the sheet. Lastly, edge painting or coating is an option worth considering. This process entails applying a protective or decorative paint or coating to the edges of the aluminum sheet. This not only provides a finished look but also helps protect the edges from corrosion or other damage. Ultimately, the choice of method for finishing the edges of aluminum sheets depends on factors such as the intended use, desired appearance, and specific project requirements.

- Q: How to clean the engine oil and kerosene on the surface of aluminum sheet?

- you can buy a bottle of petroleum ether in chemical raw material shop, it will be clean after rubbing, or you can buy solvent oil.

- Q: What oil does the aluminum plate stretch with?

- There are professional tensile oil, you can ask to pull the rice cooker liner manufacturers know, if not a lot of production, you can use peanut oil first try, the effect barely enough!

- Q: Can aluminum sheets be used for electrical enclosures?

- Yes, aluminum sheets can be used for electrical enclosures. Aluminum is a popular choice for electrical enclosures due to its excellent conductivity, corrosion resistance, and lightweight properties. It is a good conductor of electricity, allowing for efficient distribution of electrical current within the enclosure. Additionally, aluminum has a high resistance to corrosion, making it suitable for outdoor and harsh environment applications. Its lightweight nature also makes it easier to handle and install. Overall, aluminum sheets are a reliable and commonly used material for electrical enclosures.

Send your message to us

Corrugated Aluminum Roofing Sheets - Aluminium Prepainted Sheet - Good Price - High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords