Aluminum Sheets Kaccha House - Aluminium Coils for Decoration Ceiling AA3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Coils for Decoration Ceiling AA3003

Aluminium Coils for Decoration Ceiling AA3003 is one semi-finished aluminium material. The coils are widly used in the building,decoration and aluminium circle. The alloy AA1050 is the most common alloy in the aluminium industry. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Aluminium Coils for Decoration Ceiling AA3003

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

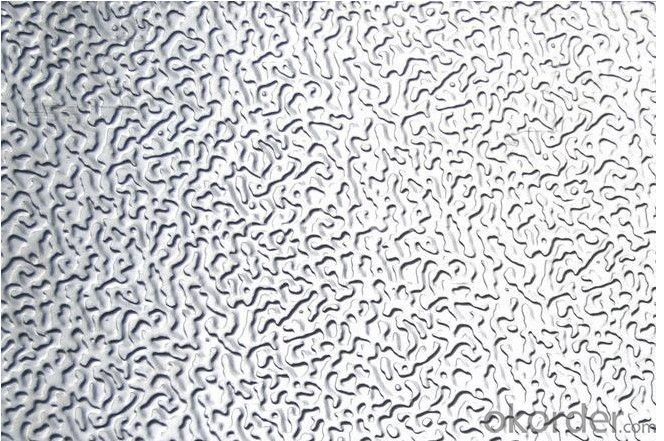

3. Image of Aluminium Coils for Decoration Ceiling AA3003

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA1100 | HO | 0.2MM-3MM | 1000-1500MM | Max 3 tons |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Are 101 aluminum sheets suitable for aircraft manufacturing?

- Yes, 101 aluminum sheets are suitable for aircraft manufacturing. 101 aluminum is a commonly used alloy in the aerospace industry due to its high strength-to-weight ratio, excellent corrosion resistance, and good formability. It is particularly well-suited for structural components and skin panels in aircraft manufacturing. Additionally, 101 aluminum sheets can be easily machined, welded, and joined, making them versatile and efficient for aircraft construction. Overall, 101 aluminum sheets meet the stringent requirements for aircraft manufacturing and are widely used in the industry.

- Q: How do you prevent surface marring of aluminum sheets during handling?

- To prevent any damage to the surface of aluminum sheets when handling them, there are several steps that can be taken: 1. Use clean gloves or finger cots: It is important to avoid direct contact between bare hands and the aluminum sheets, as hands can contain oils, dirt, or other contaminants that may leave marks on the surface. Wearing clean gloves or finger cots acts as a barrier and prevents any transfer of substances onto the sheets. 2. Utilize protective packaging: Before handling the sheets, consider using protective packaging such as foam or plastic sheets to cover the surface. This provides an additional layer of protection against scratches or abrasions during transportation or storage. 3. Implement proper storage and handling techniques: Store the aluminum sheets in a clean and dry environment, away from any abrasive materials or surfaces. When moving or handling the sheets, ensure they are lifted or supported evenly to prevent bending or distortion that could lead to surface damage. Using appropriate lifting equipment, such as suction cups or clamps, helps distribute the weight evenly and minimizes the risk of harm. 4. Regularly clean the surface: Clean the aluminum sheets on a regular basis using a mild detergent or cleaning solution specifically designed for aluminum. This removes any dirt, grime, or other substances that could potentially cause surface damage. Ensure soft, non-abrasive cleaning tools like microfiber cloths or sponges are used to avoid scratching. 5. Implement quality control measures: Establish quality control measures during the handling process to identify any potential causes of surface damage. Conduct regular inspections to check for signs of harm or defects. Properly train employees involved in the handling process to minimize the risk of surface damage. By following these preventive measures, the chances of surface damage to aluminum sheets during handling are significantly reduced, ensuring they remain in pristine condition and maintain their quality.

- Q: Are aluminum sheets suitable for use in HVAC (heating, ventilation, and air conditioning) systems?

- Yes, aluminum sheets are suitable for use in HVAC systems. They offer several advantages such as high thermal conductivity, corrosion resistance, and lightweight nature, making them ideal for efficient heat transfer and durability in HVAC applications.

- Q: Are the aluminum sheets suitable for manufacturing kitchen utensils?

- Indeed, aluminum sheets prove to be exceptionally well-suited for the production of kitchen utensils. Boasting a lightweight and enduring composition, aluminum exhibits remarkable heat dispersal qualities. Its resistance to corrosion renders it an ideal choice for direct contact with food and liquids. Furthermore, its non-reactive nature ensures that no detrimental substances permeate the cooked or stored items. The ease with which it can be cleansed and maintained only adds to its appeal, thus cementing its popularity among kitchen utensil enthusiasts. All in all, aluminum sheets emerge as a dependable and productive alternative for fabricating an extensive variety of kitchen utensils.

- Q: What are the different surface treatments for aluminum sheets to improve corrosion resistance?

- There are several surface treatments available for aluminum sheets that can significantly enhance their corrosion resistance. These treatments include: 1. Anodizing: Anodizing is a widely used surface treatment for aluminum sheets. It involves immersing the aluminum in an electrolyte solution and applying an electric current. This creates a protective oxide layer on the surface of the aluminum, which improves its corrosion resistance. 2. Chromate Conversion Coating: Chromate conversion coating, also known as chemical film or chromating, is another common treatment for aluminum sheets. It involves immersing the aluminum in a solution containing chromate compounds. This forms a thin layer of chromate on the surface, which acts as a barrier against corrosion. 3. Powder Coating: Powder coating is a dry finishing process where a powdered polymer is sprayed onto the aluminum surface and then cured under heat. This creates a durable and corrosion-resistant coating that provides excellent protection against environmental factors. 4. E-coating: Electrophoretic coating, or e-coating, is an immersion-based process in which the aluminum sheet is submerged in an electrically charged paint bath. This attracts the paint particles to the surface, creating a uniform and corrosion-resistant coating. 5. Cladding: Cladding involves bonding a layer of a different metal, such as stainless steel or zinc, to the aluminum sheet's surface. This creates a protective barrier that shields the aluminum from corrosion. 6. Organic Coatings: Applying organic coatings, such as acrylic or polyester paints, to the aluminum surface can provide an effective corrosion-resistant barrier. These coatings form a protective film that prevents moisture and corrosive substances from reaching the aluminum. It is important to note that the choice of surface treatment depends on various factors, including the specific application, environmental conditions, and desired appearance. Some treatments may be more suitable for certain industries or environments, so it is advisable to consult with professionals to determine the most appropriate treatment for a particular application.

- Q: What are the different types of patterns available for textured aluminum sheets?

- Textured aluminum sheets offer a variety of patterns, each with its own unique visual appeal and functionality. Some commonly used patterns include: 1. Diamond pattern: Also called tread plate or checker plate, this pattern features small raised diamonds on the sheet's surface. It provides excellent slip resistance, making it ideal for applications that require traction, such as ramps, stairs, or industrial flooring. 2. Stucco pattern: Resembling a textured wall or ceiling finish, the stucco pattern has raised ridges that create a rough and bumpy surface. It is often used for decorative purposes, adding depth and visual interest to architectural elements like walls, ceilings, or furniture. 3. Hammered pattern: Mimicking the appearance of a surface hammered by hand, the hammered pattern creates a dimpled and uneven texture. It is commonly used in architectural applications, such as wall panels, backsplashes, or decorative accents, to add a rustic and artistic touch. 4. Brushed pattern: The brushed pattern is achieved by brushing the surface of the aluminum sheet with a wire brush, creating long, uniform lines. It offers a sleek and modern appearance, making it popular for applications like kitchen appliances, signage, or interior design elements. 5. Perforated pattern: Unlike the previous patterns, the perforated pattern involves creating small holes across the aluminum sheet's surface. This pattern is often used in applications that require ventilation, sound absorption, or decorative effects, such as speaker grills, filters, or façades. These examples highlight the range of patterns available for textured aluminum sheets. The choice of pattern depends on the specific project requirements, including aesthetics, functionality, and durability.

- Q: This question asks whether it is possible to utilize stamped or embossed aluminum sheets for a specific project.

- <p>Yes, you can use stamped or embossed aluminum sheets in your project. These sheets are known for their strength, durability, and lightweight properties, making them ideal for various applications such as construction, automotive, and aerospace. Stamped aluminum sheets are formed by pressing the material into a specific shape, while embossed sheets have a raised pattern. Both types offer design flexibility and can be customized to meet specific project requirements. Ensure that the aluminum sheets you select meet the necessary specifications for your project, such as thickness, strength, and finish.</p>

- Q: I have seen some stainless steel rifles that you can basically dunk in water, require no cleaning, etc and perform time after time. If SS is so good why are most weapons made of aluminum parts which is then anodized coated black? If you dunk these weapons in water will they rust? Thanks

- Their is no such thing as a corrosion proof metal. It's just corrosion resistant. Some more than others. And regardless it's going to have to be cleaned. When it comes to parts being made out of aluminum instead of steel it boils down to basically weight. Weight saving is a big thing nowadays and while aluminum is up to 5X more expensive its also 3x lighter. Also most aluminum parts on firearms are either low or no stress. Any high stress parts such as the bolt, chamber and barrel has to be made from a steel. No getting around it as aluminum wears out from those types of stresses faster.

- Q: I'd like to have the aluminum on the etching front white. Do any of the experts know that?

- After anodizing, it turns white. If not, the aluminum plate should be white and spray polyester or fluorocarbon paint,

- Q: What unique cleaning techniques should be employed when cleaning aluminum sheets?

- <p>Yes, there are special cleaning methods for aluminum sheets. It's important to use a gentle, non-abrasive cleaner to avoid scratching the surface. Avoid using harsh chemicals or abrasive materials that can damage the aluminum. Instead, use a soft cloth or sponge with a mild detergent solution. Rinse thoroughly with water to remove any cleaning residue, as some detergents can leave a film on the aluminum. Dry the aluminum sheet immediately after rinsing to prevent water spots. Regular cleaning can help maintain the appearance and longevity of aluminum sheets.</p>

Send your message to us

Aluminum Sheets Kaccha House - Aluminium Coils for Decoration Ceiling AA3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords