Aluminum Sheets for Sale Buffalo NY - Aluminium Coil for Air Conditioning Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Coil for Air Conditionnal Application Description:

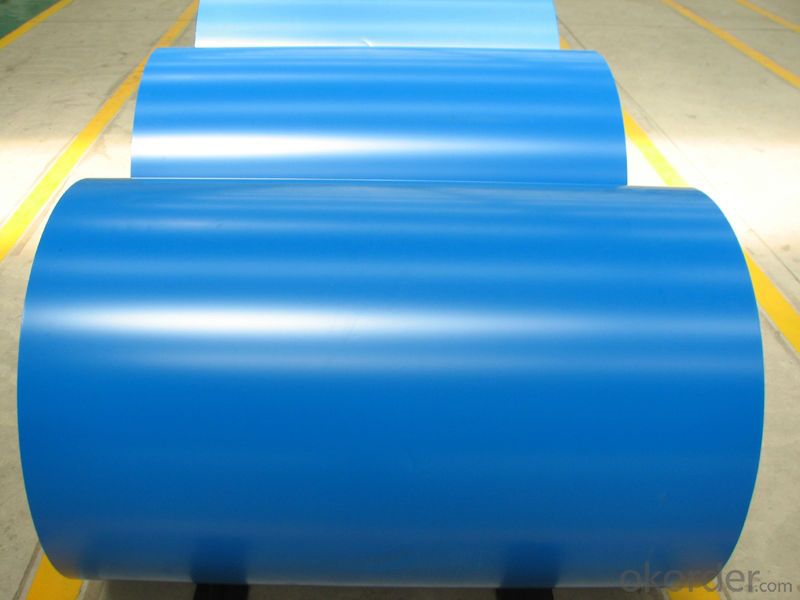

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Coil for Air Conditionnal Application:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Coil for Air Conditionnal Application:

Aluminium Coil for Air Conditionnal Application Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Coil for Air Conditionnal Application:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: This aluminum is on a mobile home. I trying to repaint it and there is alot of areas were rust has ate the metal away. Especially in the seams. How can I get rid of the rust that already exists and stop it from coming back.

- Aluminum doesn`t rust. This is probably tin. If a magnet sticks to it, treat and paint as you would steel.

- Q: 3mm heavy aluminum plate, multiple cubic meters per cubic meter?

- So the theoretical weight should be about two and a half tons of one cubic meter.

- Q: Can aluminum sheets be used in food packaging?

- Yes, aluminum sheets can be and are commonly used in food packaging. Aluminum is a popular choice for food packaging due to its excellent barrier properties, which protect the food from light, oxygen, moisture, and other external factors that can spoil or contaminate it. Aluminum sheets are lightweight, durable, and resistant to corrosion, making them suitable for various types of food packaging, such as foil wraps, containers, trays, and pouches. Additionally, aluminum is a recyclable material, making it an environmentally friendly choice for food packaging.

- Q: Can aluminum sheet be used for insulation?

- Although aluminum sheet can be utilized for insulation purposes, it is not as efficient as alternative insulation materials like fiberglass or foam. This is due to its low thermal conductivity, which implies that it is not a proficient heat conductor. Nevertheless, aluminum lacks adequate insulating properties on its own since it does not offer substantial resistance to heat flow. To enhance its effectiveness for insulation, aluminum sheet is frequently combined with other insulating materials. For instance, aluminum foil is commonly employed as a radiant barrier in buildings to reflect heat and diminish the amount of heat transferred through walls and roofs. In summary, while aluminum sheet can contribute to insulation, it is typically employed in conjunction with other materials to provide superior thermal insulation.

- Q: Can aluminum sheets be used for heat shields in appliances?

- Yes, aluminum sheets can be used as heat shields in appliances. Aluminum is a good conductor of heat, making it an effective material for dissipating and reflecting heat away from sensitive components in appliances. Additionally, aluminum is lightweight, durable, and has good corrosion resistance, making it a suitable choice for heat shield applications in various appliances.

- Q: What is the thermal conductivity of aluminum sheets?

- The thermal conductivity of aluminum sheets is approximately 205-230 watts per meter-kelvin.

- Q: How do you determine the thickness tolerance of an aluminum sheet?

- To determine the thickness tolerance of an aluminum sheet, several factors need to be considered. Firstly, it is important to refer to the industry standards and specifications for aluminum sheets. These standards typically provide guidelines and tolerances for various thicknesses of aluminum sheets, which can vary depending on the specific alloy and grade of the material. Next, it is crucial to use precise measuring equipment such as calipers or micrometers to accurately measure the thickness of the aluminum sheet. Multiple measurements should be taken at different locations on the sheet to account for any potential variations. Once the measurements are obtained, they should be compared to the specified thickness tolerance provided by the industry standards. The tolerance typically represents the acceptable range within which the actual thickness of the sheet can vary. For instance, if the specified thickness tolerance is ±0.002 inches, it means that the sheet's thickness can vary within this range. If the measured thickness falls within the specified tolerance range, the sheet is considered to be within tolerance. However, if the measured thickness exceeds the upper or lower limit of the tolerance range, it indicates that the sheet is out of tolerance and may not meet the required specifications. In some cases, it may be necessary to consult with the manufacturer or supplier of the aluminum sheet to determine the specific tolerance requirements for a particular application. They can provide additional information and guidance regarding the appropriate thickness tolerance to ensure the sheet meets the intended purpose. Overall, determining the thickness tolerance of an aluminum sheet involves following industry standards, using accurate measuring equipment, and comparing the measured thickness to the specified tolerance range. This helps ensure that the sheet meets the required specifications and can be used effectively in various applications.

- Q: Carbon costs more than aluminum. But there are manufactures who make high quality alloy frames which costs just as much, if not more slightly than mediocre carbon frames.In your opinion, which is better, stiffer, and lighter?If you need examples....umm like Cervelo's S1 or CAAD9 compared to the lower quality carbon frames.

- A high end aluminum frame would be a better choice than a mediocre carbon frame. Aluminum frames are light, and a good one could well be lighter than a lower end carbon frame. Stiffness is an overrated quality in a frame. A frame that is unrelentingly stiff can beat you up and be a chore to ride. Good frames are stiff where they need to be and compliant in the right places to make them comfortable to ride. Cannondale was one of the first companies to start building quality aluminum frames for road bikes, before any of the other major bike companies on the market today, and they continue to sell high end aluminum bikes today. Early aluminum frames had durability issues, but those problems have been resolved. Frame weight is not much of an issue. Keep in mind that the rest of the components of a bike weigh far more than the frame. You can't turn a 25 pound bike into a 15 pound bike with a better frame, the difference in weight between a top level carbon fiber frame and an aluminum frame will be much less than 1 pound, even a good steel frame will weigh less than 2 pounds more than the lightest carbon frames.

- Q: Can aluminum sheets be anodized for added durability?

- Indeed, it is possible to anodize aluminum sheets in order to enhance their durability. Anodization involves an electrochemical procedure that generates a protective oxide layer on the aluminum surface. This layer not only improves the material's appearance, but also boosts its ability to resist corrosion, wear, and scratches. By undergoing anodization, aluminum sheets acquire a robust, long-lasting finish, rendering them highly suitable for a range of applications that necessitate durability, including construction, automotive, aerospace, and electronics industries. Moreover, anodized aluminum sheets can be dyed in various colors, enabling them to exhibit enhanced aesthetic appeal while retaining their durability.

- Q: What is the elongation of aluminum sheets?

- The elongation of aluminum sheets denotes the extent to which the sheets can stretch or deform before breaking or tearing. It serves as a gauge of the material's ductility or its capability to elongate without fracturing. The elongation of aluminum sheets may differ depending on variables like alloy composition, tempering, and manufacturing techniques employed. As a general rule, aluminum sheets exhibit a notable elongation percentage, ranging from 15% to 40%. This implies that they can be bent, shaped, or stretched to a certain degree without compromising their structural integrity. The elongation of aluminum sheets emerges as a vital characteristic to contemplate in scenarios where the material must endure deformation or be molded into intricate forms.

Send your message to us

Aluminum Sheets for Sale Buffalo NY - Aluminium Coil for Air Conditioning Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords