Aluminum Roofing Coil Prices for Roof Ceiling System - Aluminum Sheet Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Sheet Coil for Roof Ceiling Systerm

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

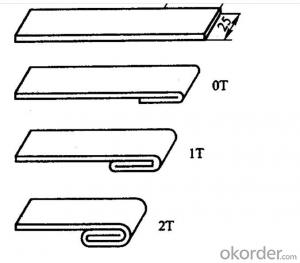

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Aluminum Sheet Coil for Roof Ceiling Systerm

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Sheet Coil for Roof Ceiling Systerm

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

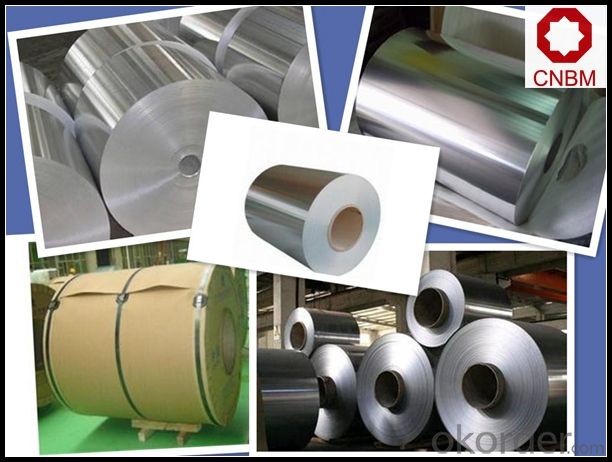

5. Image of Aluminum Sheet Coil for Roof Ceiling Systerm

6. Package and shipping of Aluminum Sheet Coil for Roof Ceiling Systerm

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the tensile strength of aluminum coils?

- The specific alloy and temper employed can cause variations in the tensile strength of aluminum coils. On average, aluminum coils exhibit a tensile strength within the range of 150 to 300 megapascals (MPa). This implies that aluminum coils can endure a pulling force of 150 to 300 MPa without succumbing to breakage or deformation. It is noteworthy that the thickness of the coil, the manufacturing technique, and any supplementary treatments or coatings administered to the aluminum can potentially impact its tensile strength.

- Q: This question asks for a method to compact an aluminum coil by folding it.

- <p>To fold an aluminum coil for compactness, first ensure the coil is free of sharp edges or damage. Use gloves for safety. Start by laying the coil flat. Measure and mark the desired folded length. Begin folding the coil by bringing one end towards the center, aligning the edges neatly. Continue folding back and forth, ensuring each fold is tight and even. Use a rubber mallet or similar tool to secure the folds, if necessary. For larger coils, consider using a mechanical folder or press to apply even pressure. Always work in a well-ventilated area and follow safety guidelines to prevent injury.</p>

- Q: Can aluminum coils be used in corrosive gas environments?

- Yes, aluminum coils can be used in corrosive gas environments. Aluminum is known for its excellent corrosion resistance, especially in atmospheric conditions. It forms a protective oxide layer on the surface that protects the metal from further corrosion. However, it is important to note that aluminum can be susceptible to certain corrosive gases, such as chloride and sulfur compounds. In such cases, additional protective measures, such as surface treatment or coating, may be necessary to ensure the longevity and performance of the aluminum coils in corrosive gas environments.

- Q: why do we use copper more than aluminum? give some characteristic of copper that makes it better then aluminum?

- Unless you have a specific purpose in mind, I don't think copper is used as much as aluminum. Aluminum was used in house wiring for a short time because it is less expensive than the usual copper, but something about it caused house fires. (I think it was thermal expansion caused connections in switches to loosen creating connections that would heat up, or spark.) Copper is preferred for house wiring. Copper is about 3 times more dense, so Al is used where light weight is a consideration. I can't remember the last time I drank something out of a copper can.

- Q: like we have seen a disk of aluminum spinning, and a permanent magnet repell the plate because apparently because of temporary hystersis and because the north or south field causes the same in the aluminum, so why wont a plate of ruby do the same thing? Are not all metals, crystals? Perhaps its just too big and difficult a question for you simple huumans,..eh?

- Hey, magnets work on iron and steel, but not on non-ferrous metals.

- Q: Are aluminum coils suitable for air conditioning systems?

- Yes, aluminum coils are suitable for air conditioning systems. Aluminum coils are commonly used in air conditioning systems due to their many advantages. Firstly, aluminum is a lightweight material, making it easier to handle and transport during installation. This also reduces the overall weight of the unit, making it more energy-efficient. Furthermore, aluminum coils have excellent heat transfer properties, allowing for efficient cooling of the air. They provide enhanced thermal conductivity, which helps in transferring heat quickly and effectively. This results in better cooling performance and improved energy efficiency, reducing electricity consumption and saving costs in the long run. Aluminum coils also offer superior corrosion resistance compared to other materials like copper. This is important in air conditioning systems, as they are exposed to moisture and humidity. Aluminum coils can withstand these conditions without corroding or deteriorating, ensuring longer lifespan and reliable performance. Another advantage of aluminum coils is their affordability. Aluminum is a cost-effective material, making it a popular choice for air conditioning manufacturers. This affordability can translate to lower costs for consumers, making air conditioning systems more accessible and affordable. In conclusion, aluminum coils are suitable for air conditioning systems due to their lightweight, excellent heat transfer properties, corrosion resistance, and affordability. They provide efficient cooling, durability, and cost-effectiveness, making them a preferred choice for air conditioning units.

- Q: Are aluminum coils susceptible to warping or bending?

- Yes, aluminum coils are susceptible to warping or bending due to their relatively low strength and flexibility.

- Q: This question asks for a brief explanation of the process involved in manufacturing aluminum coils.

- <p>To make aluminum coil, start with high-quality aluminum ingots. These are melted in a furnace and then poured into a casting machine to create a continuous cast strip. This strip is passed through a series of rollers to reduce its thickness and achieve the desired width and thickness. The rollers apply heat and pressure, gradually forming the aluminum into a coil. The coil is then cooled, often using water, and wound onto a mandrel for storage or further processing. Quality control checks are performed throughout the process to ensure the coil meets specific strength, thickness, and surface finish requirements. The final product is a tightly wound aluminum coil ready for use in various industries such as construction, automotive, and packaging.</p>

- Q: Explain how the temperature affects aluminum coil properties and behavior.

- <p>The relationship between aluminum coil and temperature is significant as temperature influences the coil's physical properties and performance. At lower temperatures, aluminum coils become more brittle and susceptible to cracking or breaking. As the temperature increases, aluminum's ductility improves, allowing it to be more easily shaped and formed. However, excessive heat can also lead to deformation and loss of strength. The thermal conductivity of aluminum is high, meaning it conducts heat well, which is useful in applications requiring heat transfer. Additionally, the electrical conductivity of aluminum is affected by temperature; as temperature rises, resistance increases, which can impact applications where electrical conductivity is critical.</p>

- Q: im doing an a level physics presentation on aluminium and im trying to compare aluminium and copper in electricity pylons.i know that copper will have a better conductance than aluminium becasue it has a lower resitivity but i need to come up with a calculation to prove why aluminium is better for use in electricity pylons? i know its down to aluminium being more lightweight than copper and also much cheaper. But im not sure how to create an calculation to show this?:) any help is greatly appreciated

- Copper has lower resistance per unit volume, ie, a 1 cm diameter copper wire has less resistance than a 1 cm aluminum wire. BUT, aluminum is much lighter than Cu for the same diameter. If you used an aluminum wire that weighs the same as the 1 cm diameter copper wire, it would have LOWER resistance. And that is why aluminum is used in power transmission, and also in aircraft, where weight is important. to do this you calculate density resistivity which is (resistivity x density). Here is a partial table: Al 28.2e-9 Ω-m * 2700 kg/m? = 76e-6 Ω-kg/m? Cu 17.2e-9 Ω-m * 8960 kg/m? = 154e-6 Ω-kg/m? Ag 15.9e-9 Ω-m * 10500 kg/m? = 167e-6 Ω-kg/m? Au 22.14e-9 Ω-m * 19300 kg/m? = 427e-6 Ω-kg/m? Zn 68e-9 Ω-m * 7130 kg/m? = 485-6 Ω-kg/m? Fe 100e-9 Ω-m * 7870 kg/m? = 787e-6 Ω-kg/m? Note that Al is half that of Cu.

Send your message to us

Aluminum Roofing Coil Prices for Roof Ceiling System - Aluminum Sheet Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords