Aluminum Cladding Sheets - Aluminium Checkered Plate for Auto Trailers Supply from CNBM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminium Checkered Plate for Auto Trailers Supply from CNBM

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Aluminium Checkered Plate for Auto Trailers Supply from CNBM

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminium Checkered Plate for Auto Trailers Supply from CNBM

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

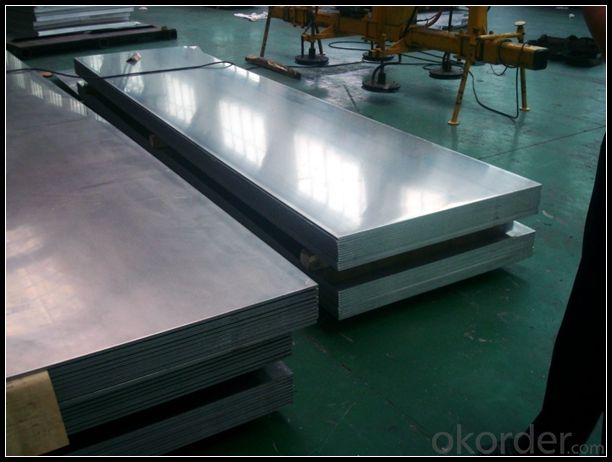

5. Image of Aluminium Checkered Plate for Auto Trailers Supply from CNBM

6. Package and shipping of Aluminium Checkered Plate for Auto Trailers Supply from CNBM

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum sheets be anodized for corrosion protection?

- Yes, aluminum sheets can be anodized for corrosion protection. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum. This oxide layer is highly resistant to corrosion and provides a durable and long-lasting protection. Anodizing can be done on various aluminum products, including sheets, to enhance their corrosion resistance, improve their appearance, and increase their lifespan. The process involves immersing the aluminum sheet in an electrolyte solution and applying an electric current, which causes oxygen ions to bond with the surface of the metal, forming the protective oxide layer. Anodized aluminum sheets are widely used in industries such as aerospace, automotive, construction, and electronics, where corrosion resistance is crucial.

- Q: Inquire whether aluminum sheets are generally more costly compared to other sheet metal materials.

- <p>Aluminum sheets are not necessarily more expensive than other types of sheet metal. The cost can vary based on factors such as the current market price of the metal, the thickness and grade of the sheet, and the specific alloy used. Generally, aluminum is less expensive than metals like stainless steel or copper, but it can be more expensive than common metals like steel or iron. Prices fluctuate, so it's best to check current market prices for the most accurate comparison.</p>

- Q: What are the different methods of surface treatment for adhesive bonding of aluminum sheet?

- There are several methods of surface treatment for adhesive bonding of aluminum sheet, including mechanical cleaning, chemical cleaning, anodizing, and conversion coating. Mechanical cleaning involves removing dirt, grease, and oxide layers through methods such as sanding, grinding, or brushing. Chemical cleaning uses solvents or detergents to remove contaminants and prepare the surface for bonding. Anodizing forms a protective oxide layer on the aluminum surface, enhancing its resistance to corrosion and improving bond strength. Conversion coating involves applying a chemical treatment to create a thin layer of metal oxide or phosphate, which promotes adhesion between the adhesive and aluminum.

- Q: Can aluminum sheets be used for architectural applications?

- Architectural applications can definitely make use of aluminum sheets. Aluminum, being a lightweight and versatile material, offers numerous advantages for architectural projects. It possesses durability, resistance to corrosion, and the ability to withstand extreme weather conditions, making it an ideal choice for different architectural applications like roofing, cladding, facades, windows, doors, and decorative elements. The availability of aluminum sheets in various thicknesses, finishes, and colors allows architects and designers to achieve their desired aesthetic while maintaining structural integrity. With the material's flexibility in being easily shaped, bent, and formed into complex designs, architects are provided with creative freedom and flexibility. Aside from its aesthetic appeal, aluminum is also an environmentally sustainable choice for architectural applications. It is highly recyclable, contributing to a high recycling rate and promoting eco-friendly options. The use of aluminum sheets in architectural projects helps in reducing the carbon footprint and promoting sustainable design practices. Moreover, aluminum sheets offer excellent thermal and acoustic properties that contribute to energy efficiency and sound insulation in buildings. The material aids in reducing energy consumption and enhancing occupant comfort, making it an attractive option for architects and building owners. In conclusion, the versatility, durability, sustainability, and aesthetic appeal of aluminum sheets make them a popular choice for architectural applications. They provide numerous benefits and can be utilized in various ways to create stunning architectural designs while ensuring long-lasting performance.

- Q: What are the different types of surface treatments available for aluminum sheets?

- There are several different types of surface treatments available for aluminum sheets, including anodizing, powder coating, painting, polishing, and brushing. These treatments can enhance the appearance, durability, corrosion resistance, and overall performance of the aluminum sheets.

- Q: Are aluminum sheets suitable for aerospace fuel tanks?

- Aerospace fuel tanks can indeed utilize aluminum sheets. In the aerospace industry, aluminum is widely employed because of its lightweight yet robust characteristics. Its strength-to-weight ratio is commendable, rendering it an ideal choice for fuel tanks that must endure the forces of flight while minimizing the aircraft's overall weight. Moreover, aluminum's resistance to corrosion is pivotal for aerospace fuel tanks, considering their exposure to diverse fuels and environmental conditions. Furthermore, aluminum's ease of fabrication and widespread availability make it a cost-efficient option for aerospace applications. In summary, aluminum sheets are a fitting material for aerospace fuel tanks due to their strength, lightweight nature, corrosion resistance, and cost-effectiveness.

- Q: Can aluminum sheets handle high temperatures?

- Certainly! High temperatures are well-tolerated by aluminum sheets. With a melting point of 660 degrees Celsius (1220 degrees Fahrenheit), aluminum proves itself suitable for various applications requiring elevated temperatures. Furthermore, aluminum possesses exceptional thermal conductivity, enabling rapid heat dissipation. This attribute renders aluminum sheets ideal for deployment in environments necessitating resistance against high temperatures, including engine components, heat exchangers, and oven linings. Nevertheless, it is crucial to take into account the specific alloy and thickness of the aluminum sheet, as different alloys may impose different temperature thresholds.

- Q: This question asks for a list of various types of aluminum profiles that are typically used in conjunction with aluminum sheets.

- <p>Aluminum profiles are extruded shapes commonly used with aluminum sheets for various applications. The different types include: 1. Angle profiles, which are used for corners and edges. 2. Channel profiles, suitable for creating channels or frames. 3. T-slot profiles, ideal for modular systems requiring adjustable components. 4. U-channel profiles, used for covering edges and creating frames. 5. H-profiles, often used in structural applications. 6. Flat bar profiles, used for simple straight edges. 7. Round and square tube profiles, used for structural support and design elements. 8. Special profiles, which are custom-made for specific applications. These profiles are chosen based on the structural needs and design requirements of the project.</p>

- Q: How to solve the loose bonding of aluminum sheet and silica gel?

- Bonding silicone rubber needs surface treatment, after using silicone rubber surface treating agent of Kuer , you can bond them with 4211 adhesive.

- Q: What is the fatigue strength of aluminum sheets?

- The fatigue strength of aluminum sheets can vary based on several factors, including the composition of the alloy, thickness, condition of the surface, and the specific loading conditions. When compared to other metals, aluminum alloys typically exhibit favorable fatigue strength. To determine the fatigue strength of aluminum sheets, fatigue testing is commonly employed. This involves subjecting specimens to cyclic loading until failure. The fatigue behavior of aluminum sheets is characterized by the S-N curve, which represents the relationship between the applied stress amplitude (S) and the number of cycles to failure (N). Aluminum alloys, such as 2024-T3 and 6061-T6, are frequently used in industries like aerospace and automotive due to their high fatigue strengths. These alloys can endure millions of cycles at specific stress levels. For instance, at 10^6 cycles, 2024-T3 aluminum alloy has a fatigue strength of approximately 105 MPa (15,000 psi), while 6061-T6 aluminum alloy has a fatigue strength of around 96 MPa (14,000 psi). It is worth noting that the fatigue strength of aluminum sheets can be influenced by various factors, including surface defects, corrosion, temperature, and loading frequency. To enhance the fatigue strength, it is important to properly prepare the surface by smoothing it and eliminating sharp edges. Additionally, the use of appropriate stress relief treatments and design considerations, such as avoiding stress concentrations and optimizing joint design, can also improve the fatigue performance of aluminum sheets. In conclusion, the fatigue strength of aluminum sheets is generally considered good. However, it is crucial to consider the specific alloy, thickness, surface condition, and loading conditions in order to accurately determine and optimize the fatigue performance in practical applications.

Send your message to us

Aluminum Cladding Sheets - Aluminium Checkered Plate for Auto Trailers Supply from CNBM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords