Lowes Aluminum Sheets - Aluminum Panel Ceiling Sheet from China Wholesaler

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

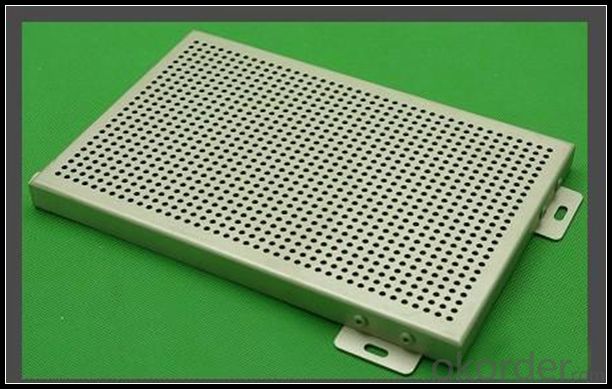

1.Structure of Aluminum Panel Ceiling Sheet From China Wholesaler

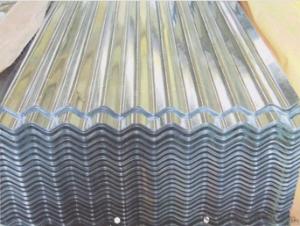

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminum Panel Ceiling Sheet From China Wholesaler

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

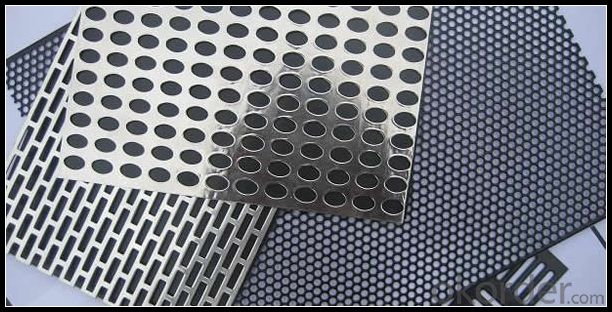

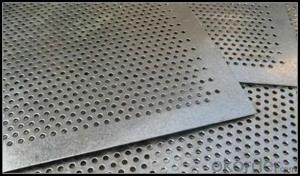

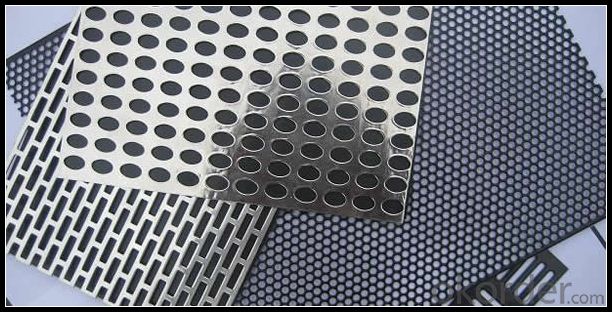

3. Aluminum Panel Ceiling Sheet From China Wholesaler Images

4.Specification of Aluminum Panel Ceiling Sheet From China Wholesaler

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: how much should the current be adjusted when I use pulse aluminum welding machine to weld 0.7 aluminum sheet?

- 60-70A current is enough for 0.7 aluminum sheet,the key poiny is that the thin sheet should be bonded with iron sheet or other assistant cooling device when you weld it, or it will be burned through.

- Q: Can aluminum sheet withstand heavy loads?

- Indeed, the durability of aluminum sheet is such that it can endure substantial loads. Renowned for its exceptional strength-to-weight ratio, aluminum proves to be an exceptional selection for endeavors necessitating both resilience and load-bearing capacities. Notably prevalent in sectors like aerospace, automotive, construction, and marine, aluminum sheets are frequently employed in scenarios involving weighty burdens. Moreover, the innate corrosion resistance of aluminum further fortifies its capacity to bear heavy loads for extensive durations. Nevertheless, it is crucial to take into account the precise grade and thickness of the aluminum sheet, as diverse alloys and thicknesses yield differing load capacities.

- Q: Can aluminum sheets be utilized as a material for constructing caravan roofs?

- <p>Yes, aluminum sheets can be used for caravan roofs. They are lightweight, durable, and resistant to corrosion, making them an ideal material for this purpose. Aluminum sheets are easy to install and maintain, and they can also reflect heat, helping to keep the interior of the caravan cooler. However, it's important to ensure that the aluminum sheets are of good quality and properly sealed to prevent water ingress and to maintain structural integrity over time.</p>

- Q: Can the aluminum sheets be used for manufacturing automotive radiators?

- Indeed, automotive radiators can be manufactured using aluminum sheets. The lightweight nature of aluminum, along with its exceptional heat transfer qualities and resistance to corrosion, make it a favored material for automotive radiators. The malleability of aluminum sheets allows for effortless shaping and sizing to meet the specific requirements of radiator construction. Furthermore, aluminum radiators outperform traditional copper radiators in terms of cooling efficiency. Consequently, employing aluminum sheets for the production of automotive radiators is a feasible and beneficial choice.

- Q: I deal with aluminum plate material 2A12, thickness 14mm, crack, same temperature treatment, diameter 8mm aluminum bars, no cracks, original aluminum plate quenching crack, and aluminum plate, the material is closed

- If the material is right may be burned, a full air bubble is parts of the surface, whether the intergranular cracking section, part to do see the metallographic analysis of grain size, lower furnace installed furnace capacity amount control too much away from the direction of the thermocouple parts temperature indicator indicates the temperature to the temperature time lag of thermocouple thermocouple has high temperature parts away from the direction. 510 is enough to regularly test the stove uniformity and precision with 2 kinds of stove fan check

- Q: For example, now the price of aluminum is 30000 yuan / ton. How much is that 2mm aluminum sheet with 1 square meters? What's the formula?What about the stainless steel plate, iron plate, and galvanized sheet? Can these (yuan / ton) be converted into (yuan / square)?Hurry! Which expert can I help you?!

- Know that the density of aluminum is 2.7 g / cubic centimeter or 2700 kg / cubic meterThen 2mm thick aluminium plate with a weight of 1 square meters is:M= P *v=2700*1*0.002=5.4 (kg)=5.4*10^ (-3) tonsThe price of aluminium is 30000 yuan / ton nowTherefore, the title of the money required should be 30000* (5.4*10^ (-3)) =162 yuanEmpathy,The density of iron is 7.8 KG/M3The density of stainless steel is 7.52-7.75 KG/M3The same is true of galvanized sheets, as long as the density is known

- Q: My aluminum storm windows are wasting energy in my home, however, the $7000 estimate to replace them is beyond (well beyond) my comfort zone.I know aluminum is a great conductor of hot and cold. I was considering cleaning the frames, and then coating them with a brush on clear or possibly white liquid rubber to reduce the conductivity. Any idea as to how much benefit I'll realize? Is flammability going to be an issue?I need some solid answers please. Trolls go get your two points elsewhere.Thanks.Your help is much appreciated.

- Coating your existing aluminum windows will help absolutely zero. To be effective, you would need a thermal break between the aluminum and the heated portion of your house. Unless you have aluminum storms applied directly to aluminum windows, you should already have some kind of thermal break. At the end of the day, the aluminum is not really costing you much in terms of energy loss. Adding any kind of coating to the storms does not help because it is not between the aluminum and your heated area. I can't think of a way you could do this anyway. Aluminum is incredibly hard to get a coating to stick to and I have never seen a product that would be suitable for this.

- Q: Are the aluminum sheets suitable for manufacturing aircraft wings?

- Yes, aluminum sheets are suitable for manufacturing aircraft wings. Aluminum is widely used in the aerospace industry due to its excellent strength-to-weight ratio, corrosion resistance, and high thermal conductivity. These properties make it an ideal choice for constructing lightweight yet durable aircraft components, such as wings. Aluminum sheets can be easily formed, welded, and machined, allowing for complex wing designs. Additionally, aluminum's low density helps reduce the overall weight of the aircraft, improving fuel efficiency and maneuverability. Overall, the use of aluminum sheets in manufacturing aircraft wings is a common and proven practice in the aviation industry.

- Q: What is the typical electrical conductivity of aluminum sheets?

- Aluminum sheets typically exhibit an electrical conductivity ranging from 35.0 to 45.0 MS/m (mega siemens per meter) or 35,000 to 45,000 S/m (siemens per meter). Renowned for its exceptional electrical conductivity, aluminum possesses approximately 61% of the conductivity found in copper. As a result, aluminum is extensively used in diverse electrical applications, including wiring, power transmission lines, electrical busbars, and electrical equipment components. The conductive nature of aluminum facilitates the seamless and dependable flow of electric current, rendering it an invaluable material within the electrical industry.

- Q: Aluminum plate belongs to steel or non ferrous metal?

- Of or consisting of pure aluminum or aluminum alloy material made by pressing (cutting or sawing); a rectangular material with a rectangular cross section and a uniform thickness. See China ferroalloy on line

Send your message to us

Lowes Aluminum Sheets - Aluminum Panel Ceiling Sheet from China Wholesaler

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords