Al-Zinc Coated steel Rolled coil for roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

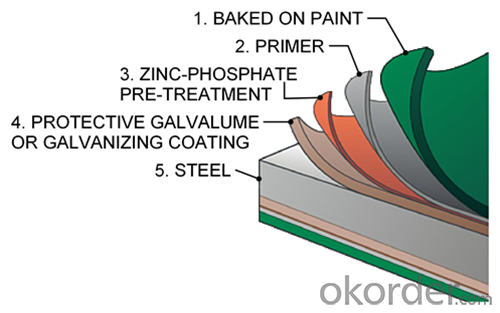

Structure of Al-Zinc coated steel coil

Description of Aluminum Zinc Rolled Coil

Aluminum zinc coils is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Al-Zinc coated steel coil

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Al-Zinc coated steel coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Al-Zinc coated steel coil

Prepainted galvanized steel coil ( PPGI ) | Prepainted galvalume steel coil ( PPGL ) | |

Standard | JIS G3312 CGCC | J IS G3322 CGLCC |

Valid thickness | 0. 16 ~1. 2 0mm | 0. 16 ~1. 2 0mm |

Coil width | 600~1250mm | 600~1250mm |

Coil ID | 508mm & 610mm | 508mm & 610mm |

Coil weight | 3~5 tons | 3~5 tons |

Coating | 4 0~275 g/m2 | AZ30 to AZ150 |

Paint t hickness , top side | 15~25 microns | 15~25 microns |

P aint t hickness , reverse | 5~7 microns or 15~25 microns | 5~7 microns or 15~25 microns |

Color | any RAL code | any RAL code |

Package | vertical, eye to sky & horizontal | vertical, eye to sky & horizontal |

MOQ | 25 tons | 25 tons |

FAQ of Al-Zinc coated steel coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the dimensions of steel coils used in the appliance industry?

- The dimensions of steel coils used in the appliance industry can vary depending on the specific application and requirements. However, the most common dimensions for steel coils used in the appliance industry are typically around 0.015 to 0.035 inches (0.38 to 0.89 millimeters) in thickness, 24 to 36 inches (61 to 91 centimeters) in width, and weighing between 1,500 to 10,000 pounds (680 to 4,535 kilograms). These dimensions allow for efficient handling, transportation, and processing of the steel coils in the appliance manufacturing process. It is important to note that these dimensions can vary and should be confirmed with the specific manufacturer or supplier for accurate and up-to-date information.

- Q: What is the purpose of steel coils?

- The purpose of steel coils is to efficiently store and transport large quantities of steel in a compact and secure manner.

- Q: How are steel coils used in the production of pipelines?

- Steel coils are used in the production of pipelines as they are rolled into flat sheets and then formed into the required shape. These coils provide the necessary strength and durability for the pipelines, ensuring they can withstand the high pressure and harsh conditions they will be exposed to.

- Q: My boyfriend says he has balls of steel.

- Easy to test. Put a magnet near them. If they attract, then they're made of steel. I'd be willing to bet I'd know what will happen, though! I know you can get metal hip replacements but .........

- Q: How are steel coils used in the manufacturing of exhaust manifolds?

- Steel coils are used in the manufacturing of exhaust manifolds as they provide the raw material for creating the manifold's structural components. These coils are typically cut, shaped, and welded to form the intricate and durable design required for efficient exhaust gas flow.

- Q: How are steel coils used in the production of steel containers?

- Steel containers rely heavily on steel coils as a vital component in their production. These coils, made from flat-rolled steel, serve as the foundation for the container's main body. To start the process, the steel coils are unwound and fed into a rolling mill. Here, they undergo a sequence of procedures to shape and mold the steel. One of these steps involves heating the coils to a specific temperature, making them more malleable and easier to manipulate. Subsequently, the hot coils pass through a series of rollers that gradually reduce their thickness and elongate them to the desired size. This entire procedure is referred to as hot rolling. Once the steel coils have been rolled to the necessary thickness, they are then cooled and transformed into sheets. These sheets are further treated to eliminate any imperfections or irregularities, guaranteeing a smooth and even surface. This is accomplished through processes like pickling, where acid is used to remove any scale or rust, and cold rolling, where the sheets are passed through rollers at room temperature to achieve the desired thickness and surface finish. After the sheets have been cleaned and refined, they are molded into the shape of the container. This typically involves a technique known as stamping, in which hydraulic presses are used to press the steel sheets into a mold. The mold determines the container's shape and size, and the steel sheets are pressed against it with great force, resulting in the desired container shape. Once the containers have been formed, they undergo several finishing processes, including welding, painting, and coating. These processes are carried out to enhance the containers' durability, appearance, and resistance to corrosion. These final touches ensure that the steel containers meet the necessary standards and are of high quality for their intended use. In conclusion, steel coils are of paramount importance in the manufacturing of steel containers, as they provide the raw material needed for their production. Through a series of steps, the steel coils are shaped, cut, and formed into sheets, which are then further processed and molded into the desired container shape. The outcome is a robust and dependable steel container suitable for various applications across industries.

- Q: I have lung cancer. My doctor told me to invest in stainless steel pots to cook with, instead of magnalite. What's the difference between the all stainless steel pots and the Hard-Anodized pots? and are there any stainless steel pots that are nonstick?

- The difference in stainless steel cookware is the amount of different metals used when making them. 18-10 is the best combination. I have Tramontina SS pots and pans and love them. Nice heavy bottoms that evenly heat. Getting used to cooking with stainless is a bit difficult. You need to start with high heat and then turn it down when you add ingredients. This assists in food not sticking.

- Q: For robotics homework, I need to find out how steel is galvanized and why. I researched a little bit, and I'm not sure I grasp the entire concept. Simple words would be helpful :) Thank you!!!

- Steel can be galvinised by electroplating process. Galvinising means providing a zinc coating on steel surface. It protects the material from rusting and loosing the shinining.

- Q: I have heard of Cold Rolled steel, Castle Forged steel and Valerian steel and i was just wondering the difference between them.I know Valerian steel is by far the strongest and durable but what about the other two types? Do you know because i haven't read all the books yet.

- Cold rolled steel is referring to rolled steel. It is referring to weapons made from rolled steel that is unrolled and stamped out. In real-life, rolled steel isn't nearly as strong as steel that is cast and forged. Think of a cheap dinner fork that you can easily bend and a nice dinner fork you can't bend at all. The cheap fork is stamp-pressed out of rolled steel and the nice fork is cast. In Game of Thrones, cold rolled steel is crap, but it's cheep and common. Castle forged steel is the best most people have available, much higher quality than cold rolled steel. Presumably it's forged in the castles of Westeros, including King's Landing. Valerian steel is special, rare steel that was anciently forged that is stronger than any other steel. They no longer make Valerian steel since the fall of Valeria. As such, the only Valerian steel available is by getting it from things already made. In real-life, it might be comparable to the extremely high quality steels forged into ancient katanas, ninja fighting swords from Japan. The Lanisters took a sword made of Valerian steel that had been passed down to Ned Stark and had it melted down, recast, then forged into two smaller swords.

- Q: haii, i have this guitar thats quite old and im not quite sure whether to put steel strings on it. there were very thin badly worn steel strings on it when i got it, so i think its an acoustic

- if you can get a good picture of the bridge i can tell for sure i thing steel

Send your message to us

Al-Zinc Coated steel Rolled coil for roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords