Al-Zinc coated steel coil For Construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

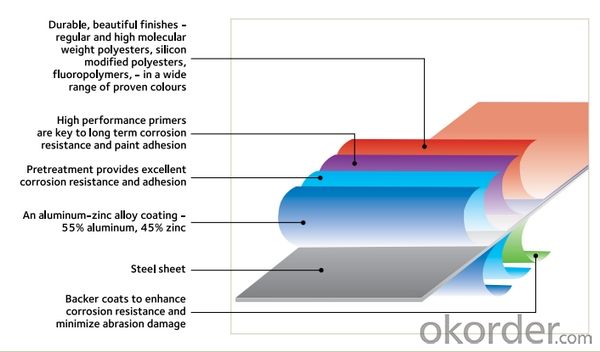

Structure of Al-Zinc coated steel coil

Description of Aluminum Zinc Rolled Coil

The detailed information for the Al-Zinc coated steel coil is as following and it is mainly using for roofing producing, making ceiling grid and all kinds of roll forming structure.

Thickness: 0.20mm to 1.20mm

Width: 914mm, 1000mm, 1200mm, 1219mm and 1250mm, or slit narrow strip according to customer request, can be slit from 20mm to 610mm.

Coil ID: 508mm

Coil weight: 3 tons to 6 tons

Thickness tolerance: +/- 0.02mm or according to customer request.

Main Feature of Al-Zinc coated steel coil

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Al-Zinc coated steel coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Al-Zinc coated steel coil

Prepainted galvanized steel coil ( PPGI ) | Prepainted galvalume steel coil ( PPGL ) | |

Standard | JIS G3312 CGCC | J IS G3322 CGLCC |

Valid thickness | 0. 16 ~1. 2 0mm | 0. 16 ~1. 2 0mm |

Coil width | 600~1250mm | 600~1250mm |

Coil ID | 508mm & 610mm | 508mm & 610mm |

Coil weight | 3~5 tons | 3~5 tons |

Coating | 4 0~275 g/m2 | AZ30 to AZ150 |

Paint t hickness , top side | 15~25 microns | 15~25 microns |

P aint t hickness , reverse | 5~7 microns or 15~25 microns | 5~7 microns or 15~25 microns |

Color | any RAL code | any RAL code |

Package | vertical, eye to sky & horizontal | vertical, eye to sky & horizontal |

MOQ | 25 tons | 25 tons |

FAQ of Al-Zinc coated steel coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Steel used to be made in the #92;Bessemer Converter, write about how steel making processes today produce better quality steel????

- Steel making today is a faster process as use Blast furnace which Coke Limestone Iron ore are fed into the top of the furnace. after these are fed in a exothermic happens and converts these ores into Iron. Iron is not strong enough to be used in thing this is formally known as pig iron. To convert Iron ore into steel it has to go to a process called the BOS Basic Oxygen Steel-making were oxygen is blown onto the iron ore for about 30 to 45 min and this then turns it into steel as all the impurities are taken out and this floats on top and known as slag and used for things such as road building. Once you have steel this is then pored into ladles and taken to the continuous caster and rolled into slabs, billets and bars and then cut off and rolled into a finished products and then taken to compniaes to be made into thins you see made out off metal such as skyscrapers. Hope this helps :o)

- Q: How are steel coils processed for cold rolling or hot rolling?

- Steel coils are first unwound and inspected for any defects. Then, they are cleaned and treated to remove any impurities. For cold rolling, the coils are passed through a series of rollers at room temperature to reduce their thickness and improve their surface finish. On the other hand, for hot rolling, the coils are heated to high temperatures and then passed through rollers to achieve the desired thickness and shape.

- Q: What are the common packaging defects in steel coils?

- Steel coils can have various packaging defects. These include edge damage, rust or corrosion, coil slippage, coil damage during handling, inadequate protection against impacts, improper coil strapping or banding, and insufficient labeling or identification. When the edges of the steel coil are not properly protected or wrapped, it can lead to dents, scratches, or deformities. This compromises the coil's integrity and can result in reduced performance or structural issues. If steel coils are not adequately protected during packaging, they can be prone to rust or corrosion. Moisture or harsh environmental conditions can cause oxidation, resulting in rust spots or widespread corrosion. This weakens the steel and makes it less suitable for its intended use. Improper packaging can cause the coils to shift or slip within the packaging material during handling or transportation. This can lead to misalignment, deformation, or interlocking, making it difficult to separate or use the coils effectively. Rough handling, improper lifting techniques, or inadequate support can cause mechanical damage to the steel coils. This can result in dents, scratches, or more severe structural damage, impacting their functionality or performance. Steel coils need sufficient protection against impacts during transportation or storage. Insufficient padding or cushioning can lead to deformities, dents, or fractures in the coil due to impacts or collisions. If the strapping or banding used to secure the steel coils is not properly applied or tightened, it can cause coil slippage or even complete unraveling of the packaging. This creates a tangled mess of steel coils, making them difficult to handle, transport, or use. Proper labeling and identification are crucial for efficient handling, storage, and tracking of steel coils. Inadequate or incorrect labeling can cause confusion, delays, or even loss of the coils during transportation or storage. To prevent these packaging defects, it is important to follow proper guidelines, use appropriate materials, provide adequate protection, and ensure proper labeling and identification of steel coils. Regular inspections and quality checks throughout the packaging process can help identify and rectify any defects before shipping or use.

- Q: How are steel coils stored and transported?

- Steel coils are typically stored and transported in a horizontal position, either on the ground or on specially designed racks. They are often secured with steel straps or bands to prevent movement or damage during transportation. When being transported, steel coils are typically loaded onto flatbed trucks or shipping containers using cranes or forklifts. The coils are then secured in place with additional straps or chains to ensure stability during transit.

- Q: I have a Charles Daly shotgun and I'm trying to find out if it is ok to shoot steel out of. The side engravings say: Charles Daly 20 GA 3 and the other side says : KBI-HBG, PA made in TurkeyOn their website it says that the barrel on the Charles Daly 300 Field is able to shoot steel but I don't see anywhere that this is a 300 model.Im also not sure if the choke is able to shoot steel. It has no engravings on it. How can I tell if this choke will work? It is the original choke that came with the gun?

- Kbi Shotguns

- Q: I know sterling silver can tarnish, so I was just wondering, how does stainless steel hold up?

- This Site Might Help You. RE: How durable is stainless steel jewelry? I know sterling silver can tarnish, so I was just wondering, how does stainless steel hold up?

- Q: We have to do a project for school on steel mines and i need 4 PROPERTIES OF A STEEL MINE PLEASE HELP!!! URGENT!!!

- The existence of them would be a good start. Steel is produced from iron ore, not mined.

- Q: How are steel coils used in the production of steel plates?

- Steel coils are a critical component in the production of steel plates. They serve as the primary raw material for manufacturing steel plates. The process begins with the production of steel coils, which are created by heating and cooling molten steel to form thin, flat strips. These coils are then processed further in a rolling mill, where they are passed through a series of rollers to reduce their thickness and increase their length. Once the desired dimensions are achieved, the steel coils are then uncoiled and straightened. This process involves feeding the coils through a machine that removes any curvature or deformities, ensuring the strips are completely flat. The straightened coils are then cut into specific lengths to suit the required dimensions of the steel plates. After being cut, the coils undergo another crucial step known as leveling. This process involves passing the strips through a leveling machine, which eliminates any residual stress or warping that may have occurred during the production process. Leveling ensures that the steel plates have a uniform thickness and are free from any distortions, making them suitable for various applications. Once the leveling process is complete, the steel coils are finally transformed into steel plates. These plates can be further processed based on the desired end-use. They may undergo additional treatments such as heat treatment, surface finishing, or coating to enhance their strength, durability, and corrosion resistance. In summary, steel coils are the starting point for the production of steel plates. They undergo several crucial steps, including rolling, uncoiling, straightening, cutting, and leveling, to transform them into flat, uniform steel plates. These plates can then be further processed and customized for a wide range of applications in industries such as construction, automotive, shipbuilding, and manufacturing.

- Q: What are the different types of steel coil edge conditions?

- The different types of steel coil edge conditions include mill edge, slit edge, and deburred edge.

- Q: I like non-stick cookware but it dont hold up no matter how much money you spend. What isthe best kind? Is there something better then stainless steel or iron skillet? I do not care if I have to use extra elbow grease to clean a pan.

- I have a combination of them both. I have Le Creuset enameled cast iron dutch-ovens, pots and pans; as well as All Clad stainless steel saute and deep-rimmed pans which have a copper core. I have one non-stick pan that I use for cooking eggs in.

Send your message to us

Al-Zinc coated steel coil For Construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords