AISI ASTM 201 2B Surface Stainless Steel Metal Plate/Sheets Made In China

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

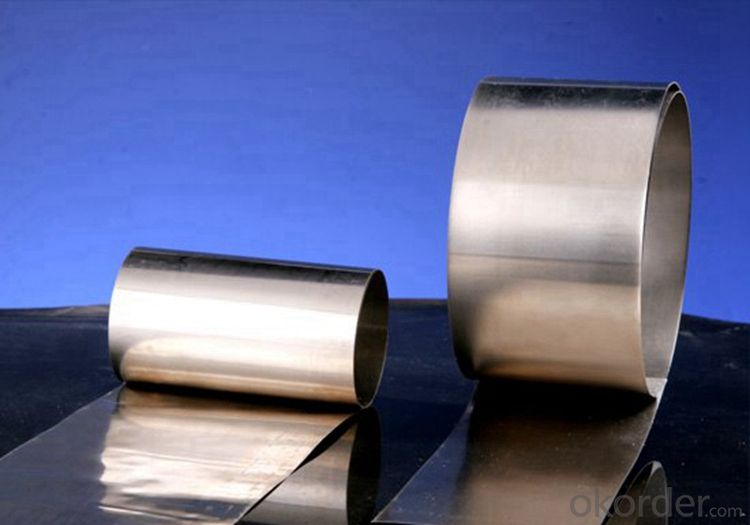

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

ITEM | DESCRIPTION |

Commodity | Stainless Steel Coil |

Material | 201, 202, 301, 321, 304, 304L, 316, 316L, 309S, 310S, 410, 430, etc. |

Surface | 2B, BA, 8K, No. 4 No.1 |

Standard | AISI, ASTM, DIN, EN, GB, JIS, etc. |

Specification | 1. Thickness : 0.3mm -120mm |

Application | 1. Automotive: Automotive trim and molding/Difficult-to-form exhaust-system |

Process | Hot rolled / cold rolled |

Payment | L/C,T/T |

MOQ | 20 Ton |

Productivity | 700 tons per month. |

Package | Standard seaworthy export packing or according to the customers' request. |

Delivery Time | It is based on the order, normally within 30 days after receiving your advance payment. |

Note | We can produce other standard as the customers' requirement. |

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Detail picture for Stainless Steel Coils/Sheets

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

Application for Stainless Steel Coils/Sheets

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: What is the coefficient of expansion of stainless steel sheets?

- The coefficient of expansion for stainless steel sheets may differ based on the particular grade or alloy of stainless steel employed. Nonetheless, as a general rule, stainless steel has a coefficient of expansion ranging from 10.8 to 16.3 x 10^-6 per degree Celsius. Consequently, for each degree Celsius rise in temperature, stainless steel sheets will expand by approximately 10.8 to 16.3 millionths of their original length. It should be emphasized that various grades of stainless steel might possess slightly different coefficients of expansion. Therefore, it is always advisable to consult the manufacturer or specific material specifications for precise information.

- Q: What's the difference between cold rolled plate and stainless steel?

- The biggest difference between the stainless steel plate is the addition of 13% chromium (Cr) elements and even nickel elements (such as the standard 304 stainless steel, chromium containing 18%, nickel containing 9%) during steelmaking, thus having the function of stainless steel

- Q: Are stainless steel sheets suitable for welding or fabrication?

- Yes, stainless steel sheets are suitable for welding and fabrication. Stainless steel is known for its excellent weldability and can be easily welded using various welding processes such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas). It also offers good formability, allowing it to be fabricated into different shapes and structures with relative ease.

- Q: Are stainless steel sheets suitable for architectural wire mesh?

- Yes, stainless steel sheets are highly suitable for architectural wire mesh. Stainless steel is a popular choice for architectural applications due to its numerous advantageous properties. Firstly, stainless steel is exceptionally durable and resistant to corrosion, making it ideal for long-term use in both indoor and outdoor environments. This resistance to corrosion is particularly important for architectural wire mesh, as it ensures the material will maintain its integrity and appearance over time. Additionally, stainless steel sheets offer excellent strength and stability, enabling them to withstand the various stresses and strains that architectural wire mesh may encounter. This is crucial in applications where the mesh needs to support structural loads or provide security. Moreover, stainless steel is available in different grades, with varying levels of strength and flexibility, allowing for customization to meet specific project requirements. Another significant advantage of stainless steel sheets is their aesthetic appeal. The sleek and modern appearance of stainless steel complements contemporary architectural designs and adds a touch of elegance to any space. Furthermore, stainless steel can be finished in different ways, such as brushed, polished, or coated, to achieve the desired visual effect. Lastly, stainless steel is a sustainable material choice for architectural wire mesh. It is 100% recyclable, reducing environmental impact and supporting green building initiatives. Additionally, stainless steel's long lifespan and low maintenance requirements contribute to its sustainability, as it minimizes the need for frequent replacements or repairs. In conclusion, stainless steel sheets are highly suitable for architectural wire mesh due to their durability, corrosion resistance, strength, aesthetic appeal, and sustainability. Their versatility and ability to meet various project requirements make them a preferred material for architects and designers in creating visually stunning and functional wire mesh installations.

- Q: What is the ductility of stainless steel sheets?

- Stainless steel sheets possess a remarkable quality known as ductility. This quality enables them to endure tensile stress without succumbing to fractures or breaks. The stainless steel material is renowned for its outstanding ductility, which grants it the ability to withstand stretching, bending, or hammering without compromising its structural integrity. This exceptional attribute endows stainless steel sheets with great versatility, rendering them suitable for an extensive array of applications such as construction, automotive manufacturing, and kitchen appliances. The high ductility of stainless steel empowers it to be effortlessly molded into intricate shapes or rolled into thin sheets, making it an ideal choice for delicate designs or structures with thin walls. Moreover, the ductility of stainless steel also facilitates easy welding, solidifying its status as a favored option for fabrication processes.

- Q: What are the applications of stainless steel sheets in the automotive industry?

- Due to their advantageous properties, stainless steel sheets are extensively utilized in the automotive industry. These sheets play a vital role in various automobile components, contributing to the overall performance, durability, and aesthetics of vehicles. A key application of stainless steel sheets in the automotive industry is seen in the manufacturing of exhaust systems. With its high resistance to corrosion and heat, stainless steel proves to be an ideal material for exhaust pipes. These sheets can endure the elevated temperatures generated by the engine, ensuring the longevity and reliability of the exhaust system. Furthermore, stainless steel sheets find use in the production of automotive body panels. They offer exceptional strength and rigidity, enabling the creation of lightweight yet robust body parts. The corrosion resistance of stainless steel is also advantageous, as it guarantees the long-lasting quality of the body panels, even in harsh weather conditions. Moreover, stainless steel sheets are employed in the fabrication of fuel tanks and other fluid storage components. The corrosion resistance and ability to withstand high pressure make stainless steel a suitable material for such applications. The integration of stainless steel in fuel tanks ensures their leak-free and durable nature, ultimately enhancing safety and longevity. Additionally, stainless steel sheets are utilized in the manufacture of various interior and exterior trim parts. These include decorative elements like grilles, trims, and accents, which enhance the vehicle's aesthetics. The ability of stainless steel to be polished and finished to a high shine adds an element of elegance and sophistication to the car's design. To summarize, stainless steel sheets have multiple applications within the automotive industry. They are utilized in exhaust systems, body panels, fuel tanks, and trim parts, among others. The exceptional properties of stainless steel, including corrosion resistance, heat resistance, and strength, greatly contribute to the overall performance, durability, and aesthetics of automobiles.

- Q: What are the different types of stainless steel sheet finishes?

- A variety of stainless steel sheet finishes are accessible, each possessing distinctive traits and appearances. Some of the most prevalent finishes comprise: 1. No.1 Finish: Termed "hot rolled annealed and pickled" (HRAP), this finish is the most fundamental and widely employed. It exhibits a dull, coarse surface with visible grain lines. 2. No.2B Finish: By cold rolling the stainless steel sheet and subsequently annealing it in a controlled environment, this finish is achieved. It possesses a smooth, reflective surface with a slight haze. 3. No.2D Finish: Similar to No.2B, this finish is acquired through cold rolling and annealing. However, it has a marginally rougher surface and is commonly utilized for applications not necessitating a highly reflective finish. 4. No.3 Finish: By meticulously polishing the stainless steel sheet using abrasive belts or brushes, this finish is accomplished. It presents a semi-reflective surface with a grainy appearance. 5. No.4 Finish: Termed "brushed finish," this finish is attained by utilizing fine abrasive belts or brushes to create a consistent, linear grain pattern on the surface. It exhibits a matte appearance and is typically employed in architectural and decorative applications. 6. No.6 Finish: Through further polishing the stainless steel with finer abrasives, this finish is realized, resulting in a smoother and more reflective surface. 7. No.7 Finish: Analogous to No.6, this finish is accomplished by employing even finer abrasives, culminating in a highly reflective surface with a mirror-like appearance. 8. No.8 Finish: Also known as the "mirror finish," this represents the highest level of polish achievable on stainless steel. It showcases a flawless, reflective surface that is frequently utilized in decorative and high-end applications. Besides these conventional finishes, there are also specialized finishes obtainable, such as embossed, patterned, or colored finishes, which can further augment the aesthetic allure of stainless steel sheets. The selection of a finish relies on the specific application and desired appearance, with each finish offering its own distinct advantages and characteristics.

- Q: Is stainless steel plate permitted to contact galvanized material?

- The reason why stainless steel can not be welded or contacted directly with ordinary steel is to prevent corrosion of stainless steel, not to prevent corrosion of ordinary steel.

- Q: How do you prevent chloride-induced corrosion in stainless steel sheets?

- One effective way to prevent chloride-induced corrosion in stainless steel sheets is by ensuring proper maintenance and cleaning. Regularly removing any accumulated chlorides and contaminants from the surface of the stainless steel sheets through thorough cleaning with mild detergents or specialized cleaning solutions can help minimize the risk of corrosion. Additionally, applying protective coatings or passivation treatments to the stainless steel sheets can create a barrier between the metal and chloride ions, further reducing the potential for corrosion.

- Q: What are the different types of finishes available for stainless steel sheets?

- Stainless steel sheets come in various finishes, each with its own distinct appearance and level of protection. Some commonly used finishes include: 1. No. 1 Finish: This finish is achieved by hot rolling the stainless steel sheet, resulting in a dull and rough surface that lacks reflection. It is commonly utilized in industrial settings where appearance is not the primary concern. 2. No. 2B Finish: By cold rolling the stainless steel sheet and subsequently annealing it in a controlled atmosphere, a smooth and reflective surface is obtained. This finish is widely favored in applications that require an aesthetically pleasing appearance, such as kitchen appliances and decorative trim. 3. No. 4 Finish: Also known as brushed or satin finish, this technique involves applying a series of abrasive grits to the surface of the stainless steel sheet. It creates a uniform, linear grain pattern that is often used for architectural and decorative purposes. 4. No. 8 Finish: This highly reflective finish is achieved by polishing the stainless steel sheet to a mirror-like appearance. It is commonly employed in applications that demand a sleek and sophisticated look, such as high-end architectural projects and automotive trim. 5. BA (Bright Annealed) Finish: This finish is accomplished by annealing the stainless steel sheet in a controlled atmosphere, followed by pickling or blasting to remove any oxide scale. It results in a smooth and bright surface, making it suitable for applications that require optimum corrosion resistance, such as medical equipment and pharmaceutical processing. 6. Hairline Finish: By mechanically brushing the surface of the stainless steel sheet with fine abrasive belts, a subtle and textured look is achieved. This finish can be utilized for architectural and decorative purposes. 7. Embossed Finish: This finish entails imprinting a raised or recessed pattern onto the surface of the stainless steel sheet using a rolling mill or press. It adds texture and visual interest to the sheet and is commonly employed in applications like elevator interiors, wall cladding, and signage. These are just a few examples of the numerous finishes available for stainless steel sheets, each offering its own unique aesthetic and functional properties. The selection of the appropriate finish depends on the specific application and desired appearance.

Send your message to us

AISI ASTM 201 2B Surface Stainless Steel Metal Plate/Sheets Made In China

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords