AISI A240 304 Stanless Steel Plate 8K for Elevator Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 23000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

roduct Details | |

Product name | Stainless steel plate |

Brand name | RONSCO |

Standard | ASTM A240, ASTM A480, EN10088, JIS G4305 |

Material | 304, 316L, 321, 310S, 1.4301, 1.4307, 1.4404, S31803, S32750, 904L, Monel 400, Inconel 800 |

Surface | NO.1,2B,NO.4,BA,SB,Satin,Brushed,Hairline,Mirror |

Certificate | ISO9001, CE, SGS, TUV, DNV, BV, LR, GL, NK, RMRS |

Packing | In wooden cases,in wooden pallets |

Shipment | By sea, by air, by express |

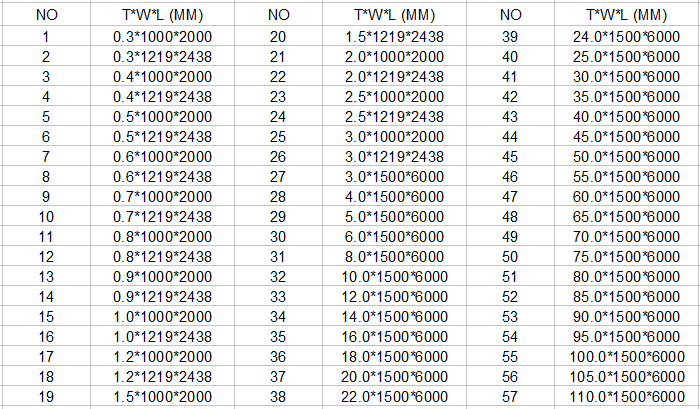

Specifications |

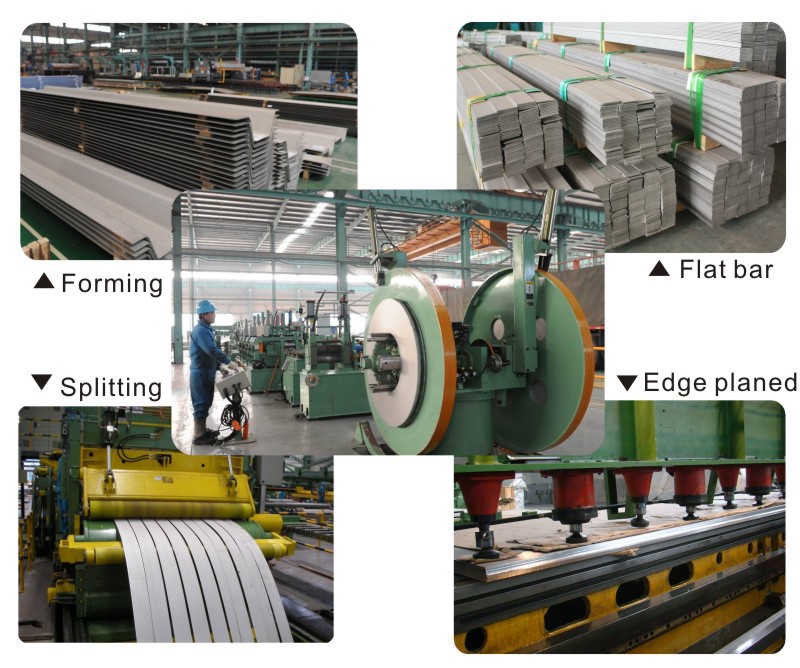

Finished Products

Stocks of the 201 stainless steel sheet

Why choose us?

19 Years specialized in processing,sales and technical services of high quality stainless steel plates and coils.

Our company located in Chariman Mao's hometown- Changsha,Hunan Province,we provide stainless steel plates and coils to our customers all over the world.

One of the biggest agent of Baosteel,TISCO in the South of China.

6 processing platform such as "Shearing,cutting,surface finish,forming,welding and machine platforms".

- Q: What are the different types of stainless steel sheets?

- There are several different types of stainless steel sheets, including austenitic, ferritic, martensitic, and duplex stainless steel sheets. Each type has unique properties and is suitable for different applications.

- Q: Can stainless steel sheets be used for elevator floors?

- Yes, stainless steel sheets can be used for elevator floors. Stainless steel is a durable and hygienic material that is resistant to corrosion and staining, making it a suitable choice for elevator flooring.

- Q: Can stainless steel sheets be used for kitchen utensils?

- Yes, stainless steel sheets can be used for kitchen utensils. Stainless steel is a popular choice for kitchen utensils because it is durable, easy to clean, and resistant to rust and corrosion. Stainless steel sheets can be shaped and formed into various utensils such as spoons, forks, knives, spatulas, and more. Additionally, stainless steel is non-reactive, meaning it does not leach any harmful chemicals into food, making it a safe option for cooking and eating utensils. Overall, stainless steel sheets are a great material choice for kitchen utensils due to their strength, hygiene, and longevity.

- Q: Are stainless steel sheets suitable for chemical transport containers?

- Yes, stainless steel sheets are suitable for chemical transport containers. Stainless steel is highly resistant to corrosion, making it an ideal material for withstanding the potentially corrosive nature of chemicals. It also offers excellent strength and durability, ensuring the safe transportation of chemicals without compromising their integrity. Additionally, stainless steel is easy to clean and maintain, which is crucial for preventing cross-contamination during transportation.

- Q: Can stainless steel sheets be used for escalator cladding?

- Yes, stainless steel sheets can be used for escalator cladding. Stainless steel is a popular choice for cladding materials due to its durability, corrosion resistance, and aesthetic appeal. It can withstand heavy usage and is resistant to wear and tear, making it suitable for escalators. Stainless steel sheets can be fabricated into various shapes and sizes, allowing for customization and seamless installation on escalator surfaces. Additionally, stainless steel has a sleek and modern appearance, enhancing the overall aesthetics of the escalator.

- Q: What are the common methods of cutting stainless steel sheets?

- There are several common methods of cutting stainless steel sheets, each with its own advantages and limitations. Here are a few commonly used methods: 1. Shearing: Shearing involves using a machine with two blades to slice through the stainless steel sheet. This method is suitable for thinner sheets and produces clean, straight cuts. However, it may leave a slight burr on the edge of the cut. 2. Plasma cutting: Plasma cutting is a versatile method that uses a high-temperature plasma arc to melt and blow away the metal. It is effective for cutting stainless steel sheets of various thicknesses and shapes. Plasma cutting provides fast, precise cuts and can handle both straight and curved lines. 3. Laser cutting: Laser cutting uses a focused laser beam to cut through stainless steel sheets. It is highly accurate and produces smooth, precise cuts with minimal distortion. Laser cutting is suitable for both thin and thick sheets, but it can be slower than other methods for thicker materials. 4. Waterjet cutting: Waterjet cutting involves using a high-pressure stream of water mixed with abrasive particles to cut through stainless steel. This method is precise and can handle various thicknesses and shapes. Waterjet cutting is known for its clean edges and the ability to cut without heat-affected zones. However, it may be slower than other methods and can be more expensive. 5. Sawing: Sawing is a traditional method that involves using a saw blade to cut through stainless steel sheets. It is suitable for thicker sheets and can handle both straight and curved cuts. Sawing produces relatively clean cuts but may result in more material waste compared to other methods. These are just a few of the common methods used to cut stainless steel sheets. The choice of method depends on factors such as the thickness of the sheet, desired cut quality, shape complexity, and budget. It is important to consider the specific requirements of the project and consult with professionals to determine the most suitable cutting method.

- Q: Can stainless steel sheets be used for architectural canopies?

- Yes, stainless steel sheets can be used for architectural canopies. Stainless steel is a durable and corrosion-resistant material that can withstand outdoor elements, making it suitable for use in canopies. It offers a sleek and modern appearance and can be customized to fit various design requirements.

- Q: What are the different types of textured patterns available for stainless steel sheets?

- There are several types of textured patterns available for stainless steel sheets, including diamond, quilted, linen, and checkerplate patterns.

- Q: Can stainless steel sheets be used for water tanks or storage containers?

- Certainly, water tanks or storage containers can be made using stainless steel sheets. This material is widely chosen for these purposes because of its remarkable resistance to corrosion and durability. Its ability to resist rust and corrosion makes it perfect for storing water or other liquids. Moreover, stainless steel is hygienic and effortless to clean, which is vital for preserving the purity of stored water or food items. Furthermore, stainless steel sheets can be easily shaped and sized to meet the specific needs of the water tank or storage container. All in all, stainless steel sheets are a dependable and enduring choice for water tanks or storage containers.

- Q: Are stainless steel sheets suitable for architectural mesh applications?

- Yes, stainless steel sheets are highly suitable for architectural mesh applications. Stainless steel is a versatile and durable material that offers numerous benefits for architectural applications. It is resistant to corrosion, which is crucial for long-term performance in outdoor and high-moisture environments. Additionally, stainless steel has excellent strength and can withstand heavy loads, making it ideal for structural applications. Architectural mesh made from stainless steel sheets offers a unique combination of functionality and aesthetics. It can be used for a wide range of applications, including facades, cladding, sunshades, balustrades, and partitions. The mesh can be woven or welded into various patterns and shapes, allowing for creative and visually appealing designs. Stainless steel architectural mesh also provides excellent transparency and airflow, making it suitable for applications that require ventilation or light transmission. It can enhance the aesthetics of a building by creating a sense of openness while providing privacy and security. Moreover, stainless steel offers a high degree of customization. It can be finished in different colors and surface textures, allowing architects and designers to achieve their desired look and feel. Additionally, stainless steel is a sustainable material as it is fully recyclable and has a long lifespan, reducing the environmental impact of architectural projects. In conclusion, stainless steel sheets are highly suitable for architectural mesh applications due to their corrosion resistance, strength, versatility, and aesthetic appeal. They provide architects and designers with a wide range of options to create visually striking and functional structures.

Send your message to us

AISI A240 304 Stanless Steel Plate 8K for Elevator Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 23000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords