Ac Aluminum Coil White - Aluminum Coil/Aluminum Circle/Aluminum Sheet Famous Supplier from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Circle

1) Alloy | AA1050, AA1060, AA1100, AA1235, AA1070, AA3104, AA3003, AA3004, AA3105, AA5005, AA5052, AA8011etc |

2) Temper | O/H12/H14/H16/H18/H32/H34/H36/H38//H22/H24/H26/H28/T6/T651/T3/T351 etc |

3) Thickness | 0.2mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | AluminIum |

7) Coil Inner diameter | 76mm, 152mm or as required |

2. Application of Aluminum Circle

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors.

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations.

(3).Advertisement: display platforms, signboards, fascia, shop fronts.

3. Feature of Aluminum Circle

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

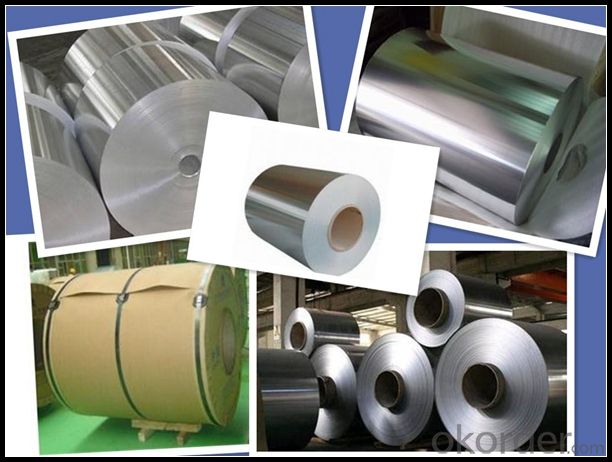

5. Image of Aluminum Circle

6. Package and shipping of

eye to wall

eye to the wall with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 30 to 35 days

2)What is the QC system:

We have QC staffs of 20 person and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) Where is your mainly market?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How are aluminum coils used in the automotive industry?

- Due to their numerous advantages over traditional materials, aluminum coils play a crucial role in the automotive industry. They are widely used in various parts and components of vehicles, enhancing performance, improving fuel efficiency, and reducing overall weight. A primary application of aluminum coils in the automotive industry is in the manufacturing of heat exchangers, such as radiators and condensers. Aluminum's excellent thermal conductivity enables efficient heat transfer, regulating engine temperature and optimizing performance. By incorporating aluminum coils in heat exchangers, vehicles can achieve better cooling efficiency, preventing engine overheating and maintaining optimal operating conditions. Furthermore, aluminum coils are utilized in the production of air conditioning systems, specifically in the condenser and evaporator units. These coils have excellent heat exchange capabilities, enabling efficient cooling or heating of the vehicle's interior. As a result, vehicles equipped with aluminum coil-based air conditioning systems can provide a comfortable environment for passengers while minimizing energy consumption. Moreover, aluminum coils are used in constructing lightweight body panels and structural components like doors, hoods, roofs, and chassis. Aluminum's high strength-to-weight ratio makes it ideal for reducing vehicle weight without compromising structural integrity. This weight reduction leads to improved fuel efficiency, reduced emissions, and enhanced performance in acceleration, handling, and braking. Additionally, aluminum coils find application in producing electrical systems in automobiles. Their excellent electrical conductivity makes them suitable for wiring harnesses, connectors, and other electrical components. The use of aluminum coils in these systems ensures efficient transmission of electrical signals and reduces overall vehicle weight, contributing to improved fuel economy. In conclusion, aluminum coils are extensively used in the automotive industry for various purposes, including heat exchangers, air conditioning systems, body panels, and electrical components. The exceptional properties of aluminum, such as thermal conductivity, strength-to-weight ratio, and electrical conductivity, enable automakers to produce lighter, more efficient, and environmentally friendly vehicles.

- Q: Can aluminum coils be used for food processing conveyor systems?

- Yes, aluminum coils can be used for food processing conveyor systems. Aluminum is a popular choice for conveyor systems in the food processing industry due to its various beneficial properties. Firstly, aluminum is a lightweight material, which makes it easier to install and transport. This is particularly important for conveyor systems that may require frequent reconfiguration or relocation. Additionally, aluminum has excellent corrosion resistance, which is crucial in food processing environments where exposure to moisture, chemicals, and food particles is common. Furthermore, aluminum is a hygienic material that is easy to clean and maintain, ensuring food safety standards are met. Lastly, aluminum coils can be easily formed and customized to fit specific conveyor system requirements, allowing for efficient and effective food processing operations. Therefore, aluminum coils are a suitable choice for food processing conveyor systems.

- Q: Why 5052 turn black after annealing during the production of aluminum alloy?

- It has been sooted.

- Q: Are aluminum coils suitable for use in heating applications?

- <p>Yes, aluminum coils can be used for heating. They are known for their excellent thermal conductivity, which allows for efficient heat transfer. Aluminum's lightweight nature and resistance to corrosion make it a popular choice in various heating applications, such as in electric heating elements, heat exchangers, and cookware. However, it's important to note that aluminum's low melting point means it's not suitable for high-temperature applications and should be used within safe temperature limits to prevent melting or damage.</p>

- Q: What are the regulations and standards governing the production of aluminum coils?

- Various regulations and standards are in place to govern the production of aluminum coils, ensuring product quality, safety, and environmental sustainability. These regulations may vary depending on the country or region, but there are common industry standards that are widely recognized. One primary regulation that governs the production of aluminum coils relates to product quality and specifications. Organizations such as the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO) set specific standards that aluminum coils must meet. These standards define the physical and chemical properties that the coils must possess, such as thickness, width, tensile strength, and chemical composition. Safety regulations are also in place to protect workers and facilities involved in the production process. For example, the Occupational Safety and Health Administration (OSHA) outlines safety measures and requirements to prevent accidents and ensure safe working conditions. This includes guidelines for handling and storing aluminum coils, personal protective equipment requirements, and emergency response protocols. The production of aluminum coils is also subject to environmental regulations that aim to minimize its impact on the environment and promote sustainable practices. These regulations may include guidelines for waste treatment and disposal, the use of energy-efficient equipment, and the reduction of greenhouse gas emissions. Industry-specific organizations, such as the Aluminum Association in the United States or the European Aluminium Association in Europe, also establish voluntary standards and best practices for aluminum coil production. They collaborate with manufacturers to develop guidelines for quality control, sustainability, and continuous improvement in the industry. Overall, compliance with these regulations and standards ensures the production of high-quality aluminum coils that meet customer requirements and contribute to a sustainable and responsible industry.

- Q: Can aluminum coils be used for electromagnetic shielding?

- Yes, aluminum coils can be used for electromagnetic shielding. Aluminum is a good conductor of electricity and can effectively block or divert electromagnetic radiation. Its high conductivity and ability to create a Faraday cage make it a suitable material for shielding against electromagnetic interference (EMI) in various applications such as electronics, telecommunications, and power transmission.

- Q: Are aluminum coils available in different colors?

- Yes, aluminum coils are available in different colors. The process of coloring aluminum coils involves coating the surface with a durable finish that can be in various colors. This coating is typically achieved through a process called coil coating, where the aluminum coil is cleaned, pre-treated, and then coated with a layer of paint or other colored material. This allows for a wide range of colors to be applied to the aluminum coils, providing flexibility in design and aesthetic options for various applications.

- Q: How are aluminum coils used in packaging?

- Aluminum coils are widely used in packaging due to their excellent properties and versatility. These coils are usually made from aluminum alloy, known for its lightweight yet strong characteristics. One common application of aluminum coils in packaging is in the production of aluminum cans. The coils are rolled into thin sheets, which are then formed into cans of various shapes and sizes. The lightweight nature of aluminum makes it ideal for manufacturing cans that are easy to transport and handle, reducing overall packaging weight. Aluminum coils are also used in the production of flexible packaging materials such as foils and laminates. These materials are commonly used for packaging food products, pharmaceuticals, and other perishable goods. The flexibility of aluminum allows it to be easily shaped and formed into different packaging formats, ensuring efficient and convenient use. Another important use of aluminum coils in packaging is in the production of closures and bottle caps. Aluminum closures provide an airtight seal, protecting the contents of the package from external factors such as moisture, contaminants, or oxidation. Additionally, aluminum closures can be easily opened and closed, providing convenience to consumers. Furthermore, aluminum coils are employed in the production of blister packs, which are widely used in the pharmaceutical industry. Blister packs consist of a plastic sheet with aluminum foil lamination, creating a barrier against moisture, light, and oxygen. This packaging format ensures the integrity and safety of pharmaceutical products by protecting them from degradation or contamination. In summary, aluminum coils are extensively used in packaging due to their lightweight, strength, and versatility. These coils are transformed into various packaging formats such as cans, flexible foils, closures, and blister packs, providing durability, protection, and convenience to both manufacturers and consumers.

- Q: The user is asking if it's possible to recycle old aluminum coils to create new ones.

- <p>Yes, you can recycle old aluminum coils into new ones. Recycling aluminum is a highly efficient process, and it's very common in the industry. Aluminum has one of the highest recycling rates among metals due to its value and the energy savings associated with recycling compared to producing new aluminum from raw materials. When you recycle aluminum, it can be melted down and reformed into new coils or other products without losing its properties. This process helps conserve resources and reduces environmental impact.</p>

- Q: Aluminum coil thickness measurement, real-time measurement of aluminum coil thickness value, you can use displacement sensor?

- You should use the eddy current displacement sensor KD2306 if the object is aluminum,

Send your message to us

Ac Aluminum Coil White - Aluminum Coil/Aluminum Circle/Aluminum Sheet Famous Supplier from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords