High Quality Aluminum Coil Wholesale for Roofing and Boats - Coated Aluminum Sheet from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of coated aluminum sheet

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

2. Application of coated aluminum sheet

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of coated aluminum sheet

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

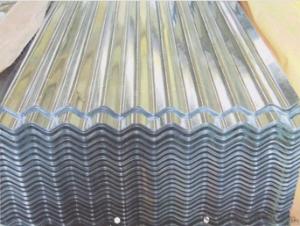

5. Image of coated aluminum sheet

6. Package and shipping of coated aluminum sheet

eye to wall

eye to the wall

with wood pallet

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used for electrical transformers?

- Indeed, electrical transformers can utilize aluminum coils. The application of aluminum as a material for transformer coils is attributed to its superior electrical conductivity and cost-effectiveness in comparison to copper. Traditionally, copper has been favored for transformer windings; nevertheless, the utilization of aluminum has gained traction in recent times due to its lighter weight and more affordable price. Additionally, aluminum coils offer advantages in terms of thermal conductivity, as they efficiently dissipate heat in contrast to copper. Nevertheless, it is crucial to take into account the specific demands and design considerations of the transformer, as the decision between aluminum and copper coils may hinge upon factors such as voltage, current, size, and insulation requirements.

- Q: I know aluminum has gone up in price. I know very little about gutter material. Durability, leaf guards, etc. I am on a limited income, and need the most and best for my few bucks. Thanks Lee

- aluminum is the best for you. plastic is junk

- Q: Can aluminum coils be used in the manufacturing of electronic devices?

- Electronic devices can utilize aluminum coils due to their versatile nature and widespread use in various industries, including electronics. Transformers, inductors, and other components of electronic devices often incorporate aluminum coils. The lightweight nature of aluminum coils is one of their major benefits in electronic devices. Compared to materials like copper, aluminum is significantly lighter, making it easier to handle and transport. Moreover, aluminum possesses excellent thermal conductivity, promoting efficient heat dissipation within electronic devices. In addition, aluminum coils exhibit resistance to corrosion, which is vital in electronic applications where exposure to moisture or harsh environments is likely. This corrosion resistance plays a crucial role in extending the lifespan of electronic devices and ensuring their reliability. Furthermore, aluminum coils can be easily shaped and sized to fit various electronic device designs. This flexibility allows for customization to meet specific requirements, such as fitting into compact spaces or achieving desired electrical characteristics. In summary, aluminum coils offer numerous advantages in the manufacturing of electronic devices, including their lightweight nature, good thermal conductivity, resistance to corrosion, and flexibility in design.

- Q: What can I get easily at Home Depot that will successfully bond rubber to aluminum?? I have tried several things with no success! Surely, there must be some sort of construction adhesive to do the job.Thanks!

- have you tried a strong adhesive such as crazy glue? i'm sure that'll bond to anything but try sand down the rubber before you put on the glue so it holds, hope i've helped?

- Q: Can aluminum coils be used for roofing?

- Yes, aluminum coils can be used for roofing. Aluminum is a popular and commonly used material for roofing due to its durability, lightweight nature, and resistance to corrosion. It is often chosen for its ability to withstand harsh weather conditions and its long lifespan, making it a suitable option for various roofing applications.

- Q: How much is aluminum-plastic panel with the 0.155mm thick aluminum per ton?

- The price is around 17000 yuan per ton, but you need to take the surface effect into account

- Q: Can aluminum coils be used in the production of aluminum composite roofs?

- Yes, aluminum coils can be used in the production of aluminum composite roofs. Aluminum coils are commonly used in the manufacturing process of aluminum composite roofs due to their durability, lightweight nature, and ability to resist corrosion. The coils can be easily formed and shaped into the desired profile for the roof, ensuring a seamless and aesthetically pleasing finish. Additionally, aluminum offers excellent thermal and sound insulation properties, making it an ideal choice for roofing applications. Its high strength-to-weight ratio also contributes to the overall structural integrity of the roof. Overall, using aluminum coils in the production of aluminum composite roofs provides a reliable and long-lasting roofing solution.

- Q: How is Aluminum formed??Thanks!!

- okorder nice.

- Q: Is it possible to utilize recycled aluminum coils for a project instead of purchasing new ones?

- <p>Yes, you can use recycled aluminum coils in your next project instead of buying new ones. Recycled aluminum is environmentally friendly and often more cost-effective. It maintains the same properties as new aluminum, making it suitable for various applications. Ensure the recycled coils meet the quality standards required for your project. Check for any impurities or damage that might affect performance. Using recycled materials not only reduces waste but also conserves resources.</p>

- Q: What are the necessary safety measures to be taken while handling and using aluminum coils?

- <p>When using aluminum coil, safety precautions include wearing appropriate personal protective equipment such as gloves and safety glasses to prevent cuts and eye injuries. Ensure good ventilation to avoid inhaling aluminum dust or fumes. Keep the work area clean and free from clutter to prevent tripping hazards. Use proper tools to handle the coils to avoid strain or injury. Be cautious of electrical hazards if the aluminum coil is being used in conjunction with electrical equipment. Always follow the manufacturer's guidelines for safe operation and storage of aluminum coils.</p>

Send your message to us

High Quality Aluminum Coil Wholesale for Roofing and Boats - Coated Aluminum Sheet from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords