Aluminum Britetread Sheets 10 - AA3XXX Mil Finished Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

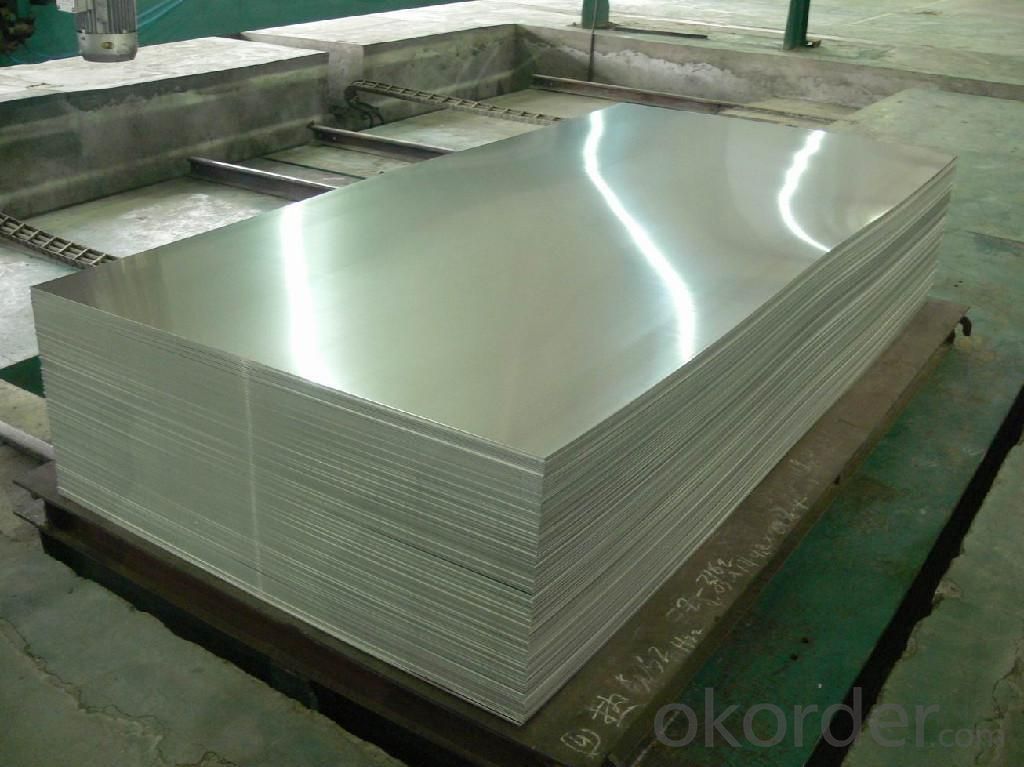

1.Structure of AA3xxx Mil Finished Aluminum Sheets Used for Construction Description

AA3xxx Mil Finished Aluminum Sheets Used for Construction one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA3xxx is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2.Main Features of AA3xxx Mil Finished Aluminum Sheets Used for Construction

1)Excellent weather-proof durability

2)Anti-ultraviolet

3)High erosion resistance

4)Stable color and gloss

5)Good mechanical processing performance

6)Abrasion resistance

7)Anti-impact

3.AA3xxx Mil Finished Aluminum Sheets Used for Construction Images

4.AA3xxx Mil Finished Aluminum Sheets Used for Construction Specification

Alloy | AA3xxx |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA3xxx Mil Finished Aluminum Sheets Used for Construction

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: The which temperature the aluminum evaporates in vacuum?

- Aluminum boils at 2519 °C (4566 °F) at normal pressure. In a vacuum, it might boil (a little) at 808 °C, but actually this is better known as subliming.

- Q: Using thin copper sheets and thin aluminum sheets, respectively, from heat source heat conduction to aluminum heat sink, which kind of efficiency is higher?

- The key is not copper or aluminum, the heat transfer coefficient between the heat source and the heat sink is more important to the overall heat dissipation effect.In theory, copper is good, but copper is relatively expensive and heat dissipation is a little too high.

- Q: Is it possible to incorporate windows made from recycled materials into a construction project?

- <p>Yes, you can use windows made from recycled materials in your project. There are eco-friendly windows available that are manufactured using recycled glass or other sustainable materials. These windows can offer similar performance to traditional ones while reducing the environmental impact of your construction. It's important to check the quality and certifications of the recycled windows to ensure they meet your project's requirements.</p>

- Q: What does everyone think about replacing aluminum bats with wooded ones in high school. More and more cities are going back to wood.........why

- I always say I'm from the times of iron men and wooden bats, so I would love to see them go back. The advantage of metal is they last a lot longer, also they are easier to keep the weights consistant, and you don't kill any trees. The ball does come off the bat a lot hotter but they have been using them long enough that I don't think it's a safety issue. I think it has to do with making the transition back to wood if they are good enough to get that far.

- Q: Are aluminum sheets suitable for food contact applications?

- Yes, aluminum sheets are suitable for food contact applications. Aluminum is a widely used material in the food industry due to its various beneficial properties. It is non-toxic, non-reactive, and corrosion-resistant, making it safe to use with food. Aluminum sheets can be easily formed into different shapes and sizes, making them suitable for a wide range of food packaging and cooking applications. Additionally, aluminum has excellent thermal conductivity, which allows for efficient heat transfer during cooking or baking. It is also impermeable to light, moisture, and oxygen, providing a protective barrier to maintain the freshness and quality of food. Overall, aluminum sheets are a popular choice for food contact applications due to their safety, versatility, and durability.

- Q: Im wondering what type of clutch would be better for my fox body mustang. A aluminum or steal. And why

- aluminum if you are drag racing ( have to learn to feather the clutch a bit) STEEL on the street( easier to keep the fire lit for mere mortals ) course you can use aluminum on the street--most people cant, because you have to be easy with the clutch-but it gives you an excuse why people cant borrow your car

- Q: Are aluminum sheets suitable for interior design applications?

- Yes, aluminum sheets are suitable for interior design applications. Aluminum is a versatile and durable material that can be used in various ways to enhance the aesthetics of interior spaces. It can be easily shaped, cut, and manipulated to create unique and modern designs. Aluminum sheets are available in different finishes, such as brushed, polished, or textured, which allows for a wide range of design possibilities. One of the main advantages of using aluminum sheets in interior design is their lightweight nature. This makes them easy to handle and install, reducing labor and transportation costs. Additionally, aluminum is resistant to corrosion, making it suitable for areas with high humidity or moisture, such as bathrooms or kitchens. Aluminum sheets can be used for various applications in interior design, including wall cladding, ceiling panels, room dividers, furniture, and decorative elements. They can be painted or coated in different colors to match any interior design scheme. Aluminum sheets can also be perforated or engraved to create patterns or intricate designs, adding a unique visual appeal to the space. Furthermore, aluminum is a sustainable material as it is highly recyclable. Its recycling process requires only a fraction of the energy needed to produce new aluminum, making it an eco-friendly choice for interior design applications. In conclusion, aluminum sheets are highly suitable for interior design applications due to their versatility, durability, lightweight nature, resistance to corrosion, and ability to be shaped and manipulated. They offer a wide range of design possibilities and can be used for various applications, making them a popular choice among designers and architects.

- Q: Aluminum does not react with oxygen.Aluminum is a very unreactive metal.Aluminum forms a tough protective coating with oxygen.Aluminum tarnishes instead of corroding.If you could explain why it would be helpful!

- Aluminum forms a tough protective coating with oxygen. The coating of aluminum oxide is not porous enough to let further oxygen through it, so the aluminum underneath is protected from further corrosion.

- Q: How to solve the loose bonding of aluminum sheet and silica gel?

- you can use YH-840 to bond silica gel and aluminum sheet in small area, and it’s hard to tear and will have an effect of destruction and melting, transparent and environmental.

- Q: Can aluminum sheet be used for reflective surfaces?

- Indeed, reflective surfaces can be achieved with the use of aluminum sheet. Renowned for its exceptional reflectivity, aluminum is widely preferred for an array of applications that call for reflective surfaces. By skillfully polishing aluminum sheets, they can attain a remarkable luster, enabling them to reflect light and produce a mirror-like effect. Consequently, they prove to be the perfect choice for applications such as lighting fixture reflectors, solar panels, mirrors, and decorative purposes. Moreover, owing to its reflective properties, aluminum is an ideal material for situations necessitating heat reflection, including thermal insulation and roofing materials. In summary, aluminum sheets offer versatility and effectiveness when it comes to generating reflective surfaces.

Send your message to us

Aluminum Britetread Sheets 10 - AA3XXX Mil Finished Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords